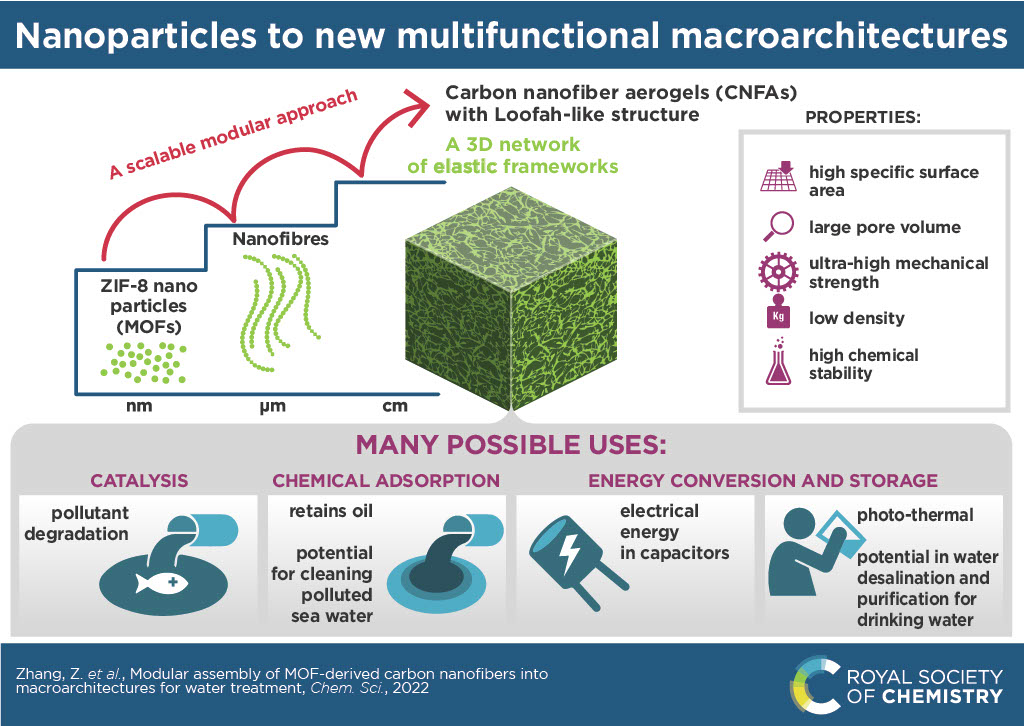

Metal-organic framework (MOF) nanoparticles combine with carbon microfibres to make large-scale materials with many possible applications

Assembling very small-scale nanoparticles into larger structures, commonly known as macroarchitectures, offers opportunities to exploit the nanoparticles’ unique chemical and physical properties while they are embodied within much larger components. Researchers in China, Australia and Japan developed a method that readily combines nanoparticles called metal-organic frameworks (MOFs) and micron-sized carbon fibres into versatile macroarchitecture materials.

The team, at Nanjing University of Science and Technology, China, the University of Queensland, Australia and the JST-ERATO Yamauchi Materials Space Tectonics Project, Japan, report their innovation in an article in the open access journal Chemical Science.

“While retaining the characteristics of the nanomaterial they are built from, our macroarchitectures also add in many new kinds of features such as high surface areas, high mechanical strength and low density,” says Professor Yusuke Yamauchi of the University of Queensland group.

From nano to macro in a simpler process

The manufacturing procedure begins with the MOF nanoparticles, which consist of metal ions or metallic clusters connected by organic (carbon-based) linker groups. Varying the metallic and organic components can generate a wide variety of MOFs with different chemical and physical properties.

The MOFs are then combined with hollow carbon-based fibres to form much larger centimetre-scale aerogels, which are highly porous and have extremely low densities. These unique materials can be generated in a variety of desired shapes, and possess great elasticity and compressibility, combined with chemical stability and physical strength.

Existing methods for making similar materials are problematic as their assembly usually yields products with relatively poor mechanical properties, and requires the use of adhesives or templates which have to be removed in additional steps. In contrast, the new method causes ‘zeolitic imidazolate framework (ZIF-8)-polyacrylonitrile nanofibers’ to directly assemble into centimetre-sized aerogels with controllable shapes and tuneable properties.

“The materials integrate the properties of one-dimensional nanofibers and three-dimensional carbon aerogels,” says Yamauchi.

Many possible uses

The macroarchitectures composed of three-dimensional porous interconnected networks could have commercial applications in many fields. The initial key to unlocking a wide range of practical uses is to design MOF structures that will achieve specific functions in each resulting aerogel. These could involve adsorbing specific chemicals into the pores of the final structure, catalysing chemical processes, or converting and storing energy, including electrical energy within capacitors.

Laboratory-scale trials have already demonstrated that some of the porous structures – which the researchers describe as “somewhat resembling that of a loofah sponge” – have impressive oil-retaining properties when exposed to mixtures of oil and water. This effect could be exploited to clean oil from polluted water. One version of the materials also has catalytic properties that could be useful for chemically degrading a variety of other pollutants.

The aerogels also have an impressive ability to absorb light and convert it into heat at high efficiency, which could be used to prepare drinkable water by desalinating seawater. “We believe that in the future our materials could be used for several large-scale and cost-effective water purification applications,” says Yamauchi.

The researchers now aim to develop the potential for moving from laboratory scale proof-of-concept demonstrations to commercially useful applications.

Chemical Science is open and free for both readers and authors.

Article details:

Zhang, Z. et al: “Modular assembly of MOF-derived carbon nanofibers into macroarchitectures for water treatment.” Chem. Sci., 2022, 13, 9159-9164