Synthesis of porous materials with tunable pore size remains a long-standing challenge for materials research. These materials, particularly hierarchical porous materials with copious different sized pores, are attractive candidates as catalysts, battery electrodes, and guest molecule hosts etc. An ideal synthesis protocol of hierarchical porous materials should be easy and capable of fine tuning pore size within a wide size range as well as able to preserve structural integrity. Unfortunately, it is extremely challenging for the currently developed methods to achieve the aforementioned three characteristics simultaneously.

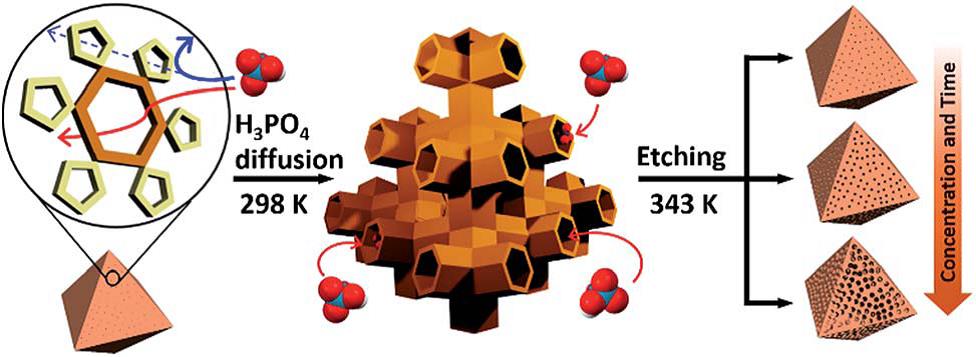

Recently, this challenge has been addressed by Kimoon Kim and co-workers from the Institute of Basic Science and the Pohang University of Science and Technology in Republic of Korea. Their strategy targeted at metal organic frameworks (MOFs), a family of highly porous crystalline materials built by interconnected metal-organic complexes, as the starting materials. Phosphoric acid was chosen to selectively break down the building blocks and create pores with tunable diameters (Figure 1). Detailed synthesis procedures are published in Chemical Science.

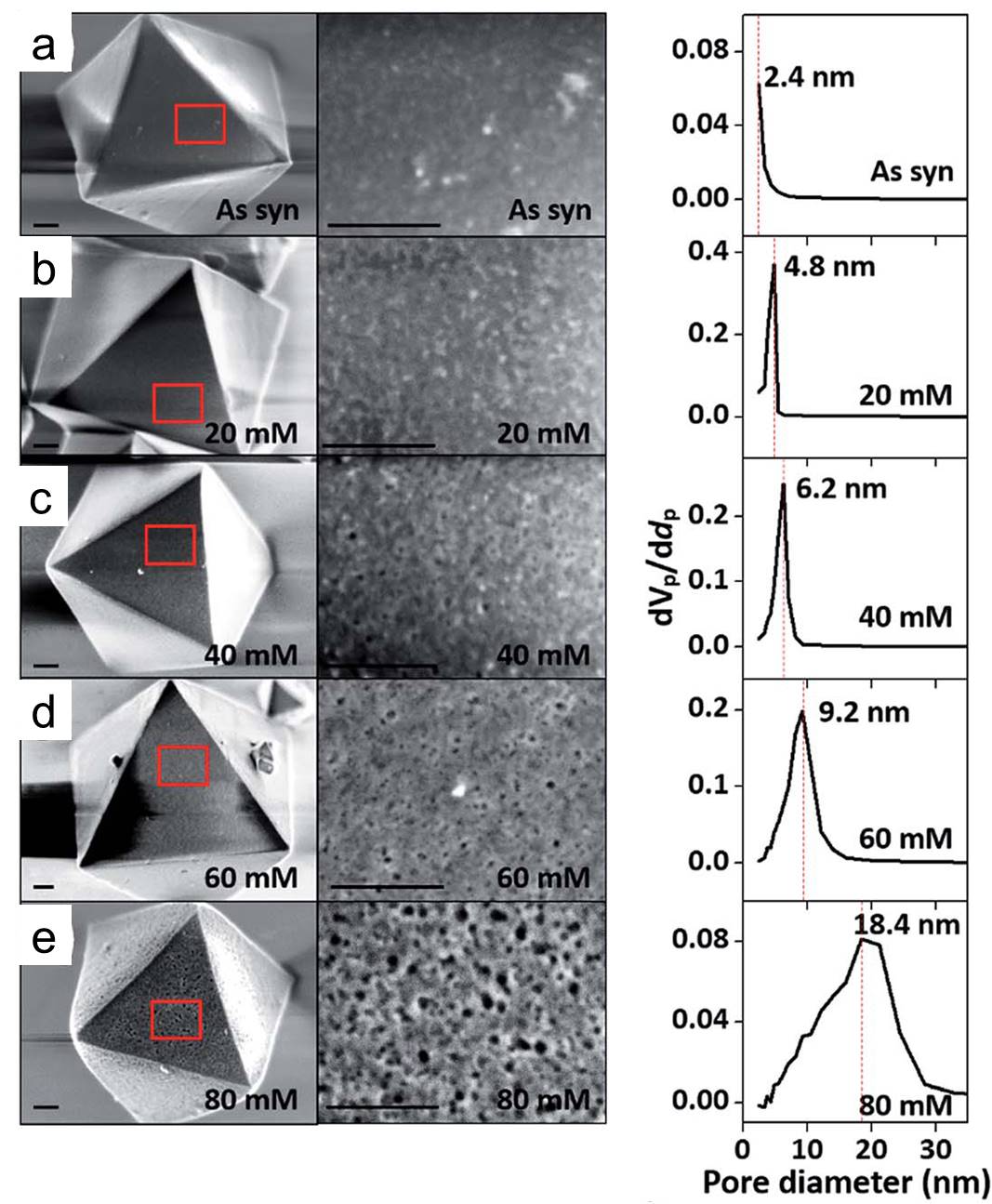

The authors specifically chose the octahedral-shaped MIL-100(Fe) MOF crystals as an example, and demonstrated that their method could readily turn the original smooth crystals into highly porous ones merely by phosphoric acid aqueous solutions. Moreover, simply changing the concentration of phosphoric acid was able to tune the diameter of the created pores from 2.4 nm to 18.4 nm (Figure 2).

Figure 2. Scanning electron microscopy images and pore diameter distributions (showing pores larger than 2 nm only) of different MOFs: (a) the untreated MIL-100(Fe) and the acid treated MIL-100(Fe) with phosphoric acid concentration of (b) 20 mM, (c) 40 mM, (d) 60 mM and (e) 80 mM. All scale bars represent 200 nm.

Structural evolution analysis revealed that the etching process initiated preferably by cleaving the coordination bonds between metal cores and organic ligands around the hexagonal windows on (2 2 0) crystal planes. It further propagated to dig out the inner part of MIL-100(Fe), forming pores on surface.

This method is expected to be applicable to other MOFs coupled with properly selected etchants, thus making the hierarchical porous crystals with tailorable porous structures readily available to worldwide materials researchers.

To find out more please read:

Jaehyoung Koo, In-Chul Hwang, Xiujun Yu, Subhadeep Saha, Yonghwi Kim and Kimoon Kim

DOI: 10.1039/c7sc02886e

About the blogger:

Tianyu Liu is a Ph.D. in chemistry graduated from University of California-Santa Cruz. He is passionate about scientific communication to introduce cutting-edge researches to both the general public and the scientists with diverse research expertise. He is a web writer for the Chem. Commun. and Chem. Sci. blog websites. More information about him can be found at http://liutianyuresearch.weebly.com/.

Tianyu Liu is a Ph.D. in chemistry graduated from University of California-Santa Cruz. He is passionate about scientific communication to introduce cutting-edge researches to both the general public and the scientists with diverse research expertise. He is a web writer for the Chem. Commun. and Chem. Sci. blog websites. More information about him can be found at http://liutianyuresearch.weebly.com/.