Maybe I’m stating the obvious, but solar cells are incredibly complex devices with more components than just the light absorber.

While the focus on the active layer by chemists looking to develop new materials is understandable, in order to truly create next-generation solar cells the other components of the architecture must be improved. Creating the crack-resistant or resilient layers necessary for functional flexible solar cells is a major challenge currently being addressed. These new materials and approaches also need to work within the general framework of fabrication techniques used for the other layers – ideally at low temperature and solution processible.

An often-neglected piece of the puzzle is the electrode. Electrodes are traditionally composed of a thin metal layer, which is often vapor deposited at high temperatures and low pressures. This class of electrodes is expensive, susceptible to degradation, and can damage the critical hole transport or active layers. One emerging alternative is carbon-based electrodes, applied as pastes. These low-cost, highly stable, and hydrophobic materials are attractive given their compatibility with emerging photovoltaic technologies, particularly perovskites. Their broad application has been limited by the necessity of toxic solvents to create the pastes, but researchers in China have developed a low-temperature, highly conductive carbon paste that can be screen printed onto perovskite solar cells without using toxic solvents.

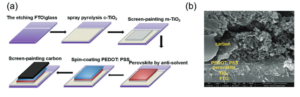

Figure 1. (a) Fabrication schematic for perovskite solar cells with carbon electrodes and hole transport layers. (b) Cross sectional SEM image of a device.

Not only are the solvents more environmentally friendly compared to those previously used, they also increase the mechanical strength of the final film and, under fabrication conditions, do not damage the perovskite active layer or organic hole transport layer. While the hole transport layer isn’t strictly necessary to create a working device, it has been shown to increase the champion efficiency from 11.7% to 14.55%. This is likely due to poor contact between the perovskite and carbon electrode, which the thin hole transport layer (PEDOT:PSS) helps remedy.

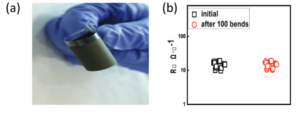

Figure 2. (a) A sample undergoing a bending test. (b) The electrode sheet resistance before and after 100 bends.

The most exciting aspect of these electrodes is their resilience when subjected to a bending test. After 100 bends, the researchers saw no visible film damage or increase in the sheet resistance when compared to the initial sample. Actual flexible solar cells fabricated and studied did show a decrease in performance after 1,000 bends, but this was attributed to known robustness issues in the base ITO layer. This work with carbon-based electrode materials could lead to simpler manufacturing for fabricating perovskite solar cells at a commercial level.

To find out more please read:

Shiyu Wang, Pei Jiang, Wenjian Shen, Anyi Mei, Sixing Xiong, Xueshi Jiang, Yaoguang Rong, Yiwen Tang, Yue Hu & Hongwei Han

Chem. Commun., 2019, 55, 2765-2768

This article is also part of the Chemical Communications ‘Perovskites‘ themed collection.

About the blogger:

Beth Mundy is a PhD candidate in chemistry in the Cossairt lab at the University of Washington in Seattle, Washington. Her research focuses on developing new and better ways to synthesize nanomaterials for energy applications. She is often spotted knitting in seminars or with her nose in a good book. You can find her on Twitter at @BethMundySci.