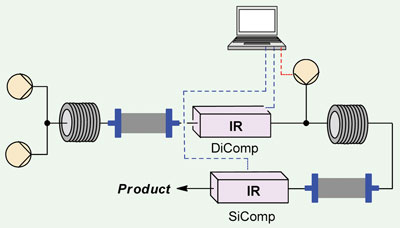

Technology that could bring flow chemistry into the domain of complex natural product synthesis has been developed by UK scientists.

The best things in life don’t come without a struggle – or so the saying goes. It certainly appears that way with chemistry. Very rarely are the chemicals desirable in a modern society made in a single step. Indeed, it is not unusual for a drug to require at least 10 distinct processes. Conventional batch synthesis can often put a considerable burden on the efficiency of these steps, demanding excess chemicals and solvents and generating large and unacceptable quantities of waste materials.

Now, a team led by Steven Ley at the University of Cambridge are advocating a more machine-assisted approach, particularly using flow chemistry techniques combined with scavenger materials to bring about multi-step operations with in-line purification.

To find out more, read the full news story in Chemistry World and download Ley’s Edge article for free from Chemical Science.

Also of interest:

Unclogging the problems of flow chemistry: US scientists have found a way to stop solid by-products clogging channels in continuous flow reactors