Microring resonators are pretty amazing things, offering label-free biosensing by coupling with light and then circulating the photons inside the cavity of the ring, enhancing the interaction between the light and the analytes.

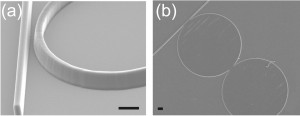

However, I like to think of traditional microring resonators as tents: difficult to construct. They require a submicrometer gap between the input waveguide and the resonator ring structure to allow the coupling of light and before you can even get to that stage, you need to make the microring resonator, which requires a series of complex fabrication steps (FIG 1a). In this Communication, which is part of ChemComm‘s Microfluidics themed web collection, Professor Jonathan Cooper and his colleagues at Glasgow University and at the International Islamic University Malaysia’s CTS Department have made (what I think of as) the double pop-up tent equivalent– or as they call it, the dual disk resonator (DDR). Made from SU8, an epoxy-based polymer used in microfluidics chips, it can be patterned in a single lithographic step. Not only that, but the DDR uses a gapless design and two rings, increasing the sensitivity of the device (FIG 1b).

FIG 1: The hard way or the easy way (a) the traditional microring resonator with submicrometer gap (b) gapless dual disk resonator

Once they had constructed the DDR, the team characterised the optical sensitivity of the device using sucrose solutions to vary the refractive index of the sample above the waveguide. They then went on to show that the sensor could be used to evaluate the dynamics of antibody interactions on surfaces, exploring avidin-biotin-based immobilisations; sharp resonance shifts confirmed the assembly and disassembly of constructs.

The simpler fabrication shows great promise, as the authors suggest that the sensitivity of the device could be greatly improved by coupling more disks to it– in which case Beyoncé might soon be singing ‘if you like it, then you should put a chain on it.’

Read this ‘HOT’ ChemComm article today:

Polymer dual ring resonators for label-free optical biosensing using microfluidics

Muhammad H. M. Salleh, Andrew Glidle, Marc Sorel, Julien Reboud and Jonathan M. Cooper

DOI: 10.1039/C3CC38228A