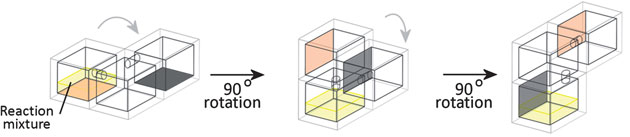

Scientists in the UK have used reactors made on a 3D printer to complete a three stage organic synthesis. The reagents, catalyst and purification step for the synthesis are completely integrated into the chambers of the sealed reactor. When the reactor is rotated, gravity pulls reactants through the different chambers to complete the synthesis.

Initially, Leroy Cronin, who lead the work at the University of Glasgow, had envisaged a ‘Rubik’s cube for synthesis’, where different manipulations of the reactor would produce different products. ‘The code, like opening a safe, would be in the rotation,’ he explains. ‘I thought it was genius. My group told me I was stupid.’ The team convinced Cronin to start with an easier L-shaped three step reactor, but he still plans to create the Rubik’s cube in the future.

A three-step organic reaction sequence was performed in the L-shaped reactor. The sequence began with…

Read the full article in Chemistry World»

Read the original journal article in Chemical Science:

Combining 3D printing and liquid handling to produce user-friendly reactionware for chemical synthesis and purification

Philip J. Kitson, Mark D. Symes, Vincenza Dragone and Leroy Cronin

Chem. Sci., 2013, Advance Article

DOI: 10.1039/C3SC51253C