We are delighted to announce this open call for papers to contribute to a themed collection for Journal of Materials Chemistry C and RSC Mechanochemistry on Mechanoluminescence, guest edited by Prof. Dr. Robert Göstl (University of Wuppertal, Germany), Prof. Wai-Yeung Wong (Hong Kong Polytechnic University, China) and Prof. Xinxing Zhang (Sichuan University, China).

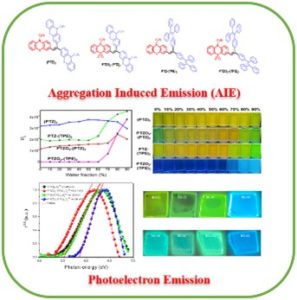

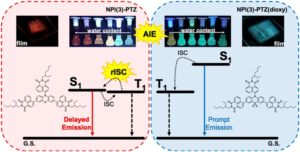

Mechanoluminescence, as the name suggests, refers to the unique fluorescence and chemiluminescence phenomena from various organic, inorganic, and polymer materials in response to mechanical force. Recently, the field of mechanoluminescence materials has attracted great attention due to its fascinating prospects in sensors, anti-counterfeiting, encryption, light sources and medical health, etc. This collection focuses on the deep understanding of mechanoluminescence materials in synthesis methods, luminescence principles and device fabrication, paving the way towards next-generation multifunctional devices and integrated smart systems.

Please consider contributing to this open call for papers for our upcoming themed collection on Mechanoluminescence to be published in Journal of Materials Chemistry C and RSC Mechanochemistry.

Submissions should fit within the scope of Journal of Materials Chemistry C and RSC Mechanochemistry. Please see the journals’ websites for more information on the journal’s scope, standards, article types and author guidelines.

This call for papers is open for the following article types:

- Communications

- Full papers

Open for Submissions until 24 October 2025

If you would like to contribute to this themed collection, you can submit your article directly to the online submission service for Journal of Materials Chemistry C or RSC Mechanochemistry. Please mention that this submission is a contribution to the Mechanoluminescence collection in the “Themed issues” section of the submission form and add a “Note to the Editor” that this is from the Open Call. The Editorial Office reserves the right to check suitability of submissions in relation to the scope of both the journal and the collection, and inclusion of accepted articles in the final themed issue is not guaranteed.

Please also note that all submissions will be subject to initial assessment and rigorous peer review to meet the usual high standards of Journal of Materials Chemistry C and RSC Mechanochemistry.

Meet the Guest Editors

Prof. Dr. Robert Göstl (University of Wuppertal, Germany)

Robert Göstl studied chemistry at the Humboldt University of Berlin. There, he obtained his diploma degree in 2011 and his doctoral degree in 2014. Afterwards, he pursued his postdoctoral research at the Eindhoven University of Technology until 2016. At the DWI – Leibniz Institute for Interactive Materials and the RWTH Aachen University he was leading an independent research group until 2024 when he became Professor for Sustainable Macromolecular Chemistry at the University of Wuppertal. He was distinguished for his career achievements by the German Chemical Society, the Royal Society of Chemistry, and the American Chemical Society. The Capital magazine selected him as Top 40 under 40.

Prof. Wai-Yeung Wong (Hong Kong Polytechnic University, China)

Wai-Yeung Wong (Raymond) obtained his B.Sc. (Hons.) and Ph.D. degrees from The University of Hong Kong. After postdoctoral works at Texas A&M University (Advisor: Prof. F. A. Cotton) and the University of Cambridge (Advisors: Profs. The Lord Lewis and P. R. Raithby), he joined Hong Kong Baptist University from 1998 to 2016 and he now works at the Hong Kong Polytechnic University as the Dean of Faculty of Science and Chair Professor of Chemical Technology. He was awarded the RSC Chemistry of the Transition Metals Award, FACS Distinguished Young Chemist Award, State Natural Science Award from China, Croucher Senior Research Fellowship and RGC Senior Research Fellow Award, among others. His research focuses on organometallic and materials chemistry, especially aiming at developing multifunctional molecules and polymers for organic optoelectronics, energy science and metal-based nanomaterials. He has served as the Associate Editor for the Journal of Materials Chemistry C from 2013 to 2022. He is currently the Chairman of Hong Kong Chemical Society and is a Fellow of the Royal Society of Chemistry. In 2023, he was elected as the Foreign Member of the European Academy of Sciences.

Prof. Xinxing Zhang (Sichuan University, China)

Xinxing Zhang received his Ph.D. degree in 2010 from Sichuan University. Currently, he is a professor of State Key Laboratory of Polymer Materials Engineering, Polymer Research Institute of Sichuan University. Prof. Zhang’s research interests include functional polymer composites and flexible devices with a focus on the interfacial dynamic bonds, including the development of mechanically robust sensors, actuators, energy devices and self-healing materials enabled by interfacial dynamic bonds.

Comments Off on Open Call for submissions: Mechanoluminescence