The ability to mimic cascade and linked enzyme reactions has potential applications for disease diagnosis and pharmaceutical manufacturing, to name just two. However, the optimisation of the ratios of the interacting enzymes can be a time consuming step when carried out using standard solution based enzyme assays. With the problem becoming exponentially more difficult with the number of enzymes in the system, Jun Ge and Zheng Liu of the Department of Chemical Engineering at Tsinghua University, with colleagues, have looked to overcome this hurdle by developing a simple, fast and high throughput method based on ink-jet printing.

The team replaced the colour inks in a standard inkjet printer with enzyme and substrate solutions. The ratio of these solutions could be controlled by varying the overall colour that was printed. Optimisation of cascade and coupled enzymatic reactions could be carried out rapidly and inexpensively compared to the standard solution based method.

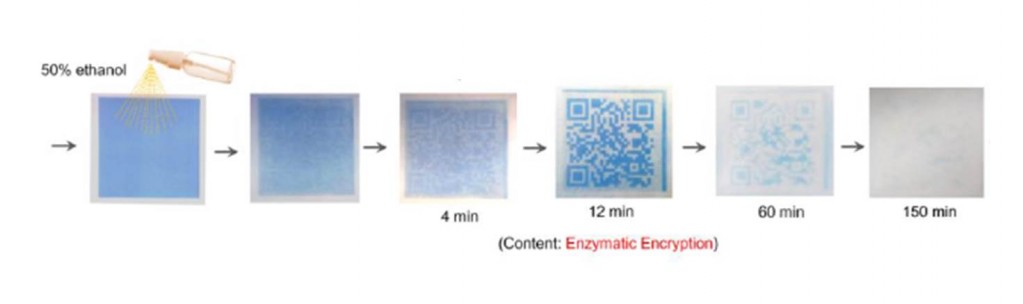

Precise two-dimensional control of enzyme placement via ink-jet printing also raises the possibility of creating 2D codes with enzymatic encryption built in, as the figure demonstrates. I don’t want to give the secret of this encryption technique away so you’ll have to read the paper today.

To read the details, check out the ChemComm article in full:

Ink-jet printing an optimal multi-enzyme system

Yifei Zhang, Fengjiao Lyu, Jun Ge, Zheng Liu

Chem. Commun., 2014, Accepted Article

DOI: 10.1039/C4CC06158F