Posted on behalf of Sarah Brown, web writer for RSC Advances

‘Waste not, want not’ my mother dearest would say, a strong proponent of cling-film and pourer of scorn on sell-by dates. She would be delighted to read that scientists have been able to produce potential scaffolds for bone grafts from beer production waste.

The waste contains phosphorous, silicon, magnesium and calcium – the main components of bone – making it an ideal candidate to develop treatments, coatings, grafts and implants for osteo-based trauma.

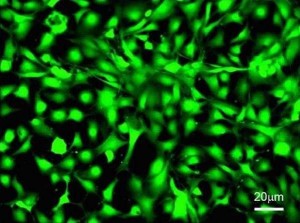

Osteoblasts grown on a 3D biomaterial matrix

Reporting their work in RSC Advances, M. Angeles Martin-Luengo and co-workers investigated the residues from three different beer production plants in Spain to determine whether their origin would affect their suitability as biomaterial precursors.

The authors performed in vitro cell proliferation assays in the presence of the beer waste materials of different plants and found no discernable difference between the different wastes. No cytotoxicity was observed either, encouraging further investigations into their use in bone tissue engineering.

One of the major advantages of using beer production waste is the reduced cost in producing these medical aids compared with conventional materials. While commercial materials currently sell at $150 per gram, beer production waste costs around $40 per ton.

In short, these potential biomaterials are environmentally and economically friendly – I’ll drink to that!

Interested in finding out more? Read the full article using the link below:

Preparation, characterization and in vitro osteoblast growth of waste-derived biomaterials

M. Angeles Martin-Luengo and co-workers

RSC Adv.,2014, 4, 12630-12639