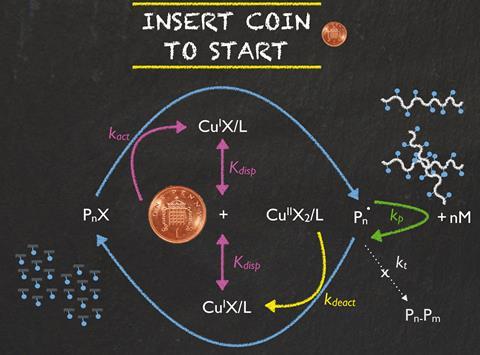

Scientists in Germany have successfully collapsed single polymer chains into dense nanoparticles, to make single-chain nanoparticles, by adding palladium.1 The nanoparticles mimic enzymatic pockets with defined environments around their metal centres and can catalyse a carbon coupling reaction.

The intramolecular crosslinking process creates single-chain nanoparticles that catalyse a Sonogashira coupling reaction

Enzymes use their carefully shaped reaction cavities to selectively catalyse organic reactions. Industrial processes crave selectivity, but also demand straightforward procedures. Synthesising and separating enzymes in practical quantities is, however, tricky, so they aren’t always suitable for industry. One solution to this might be single-chain nanoparticles, which have recently become a hot topic in the field of polymer chemistry.2 Their applications range from sensing to recognition, and medicine to catalysis, but only a few groups have studied their synthesis and even fewer have looked at the introduction of metals.

To read the full article visit Chemistry World.

Pd-complex driven formation of single-chain nanoparticles

Johannes Willenbacher, Ozcan Altintas, Vanessa Trouillet, Nicolai Knöfel, Michael J. Monteiro, Peter W. Roesky and Christopher Barner-Kowollik

Polym. Chem., 2015, Advance Article

DOI: 10.1039/C5PY00389J, Paper