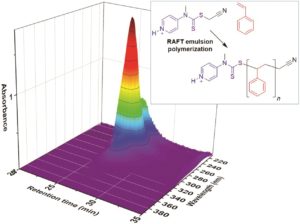

Reversible addition fragmentation chain transfer (RAFT) polymerization has revolutionized the field of polymer chemistry providing access to a wide range of materials with controlled molecular weight, functionality, end-group fidelity and dispersity. In their current contribution, the groups of Moad, Keddie and Fellows joined forces to report a range of low molar mass cationic RAFT agents that allow for predictable molecular weight and dispersity in ab initio emulsion polymerization. In particular, upon utilizing the protonated RAFT agent ((((cyanomethyl)thio)carbonothioyl)(methyl)amino)pyridin1-ium toluenesulfonate and the analogous methyl-quaternized RAFT agents, 4-((((cyanomethyl)thio) carbonothioyl)(methyl)amino)-1-methylpyridin-1-ium dodecyl sulfate, styrene could be efficiently polymerized yielding polystyrene with narrow molecular weight distributions (Đm 1.2–1.4). The authors attribute the success of ab initio emulsion polymerization with the former RAFT agent to the hydrophilicity of the pyridinium group which allows for the predominant partition of the water-soluble RAFT agent into the aqueous phase. The RAFT agent also gives minimal retardation. In addition, by employing 4-((((cyanomethyl)thio) carbonothioyl)(methyl)amino)-1-methylpyridin-1-ium dodecyl sulfate, a “surfactant-free” RAFT emulsion can be achieved producing a low Đm polystyrene although the RAFT end-group was lost upon isolating the polymer. Additional preliminary experiments were also performed demonstrating that this class of RAFT agents can be broadly applicable in ab initio emulsion polymerization of a range of other more-activated monomers including acrylates and methacrylates producing low dispersity polymers while the polymerization of less activated monomers such as vinyl acetate showed good control over the molecular weight, albeit broader molecular weight distributions. The authors are currently investigating such systems to establish their full utility in emulsion polymerization and develop robust and scalable conditions for the formation of block copolymers.

Tips/comments directly from the authors:

There are two significant challenges in implementing successful ab initio emulsion polymerization in a high throughput platform such as the Chemspeed®

- Devising a protocol for vortexing/agitating so as to form, and then maintain, a stable latex. The protocol reported was the end-result of many experiments.

- Degassing the reaction medium. RAFT polymerization can be successfully carried out in non-degassed media. However, for good reproducibility, optimal dispersity, high end group fidelity and acceptable polymerization rates, degassing remains important. In conducting experiments on the Chemspeed®, it is important to make sure the media to be dispensed by the robot are degassed, and that all of the solvent lines, and the solvent used to prime and wash the syringe needles are degassed.

Read the full article for FREE until 6th December!

Ab initio RAFT emulsion polymerization mediated by small cationic RAFT agents to form polymers with low molar mass dispersity, Polym. Chem., 2019, 10, 5044-5051, DOI: 10.1039/C9PY00893D

About the Web Writer

Dr. Athina Anastasaki is an Editorial Board Member and a Web Writer for Polymer Chemistry. Since January 2019, she joined the Materials Department of ETH Zurich as an Assistant Professor to establish her independent research group.

Dr. Athina Anastasaki is an Editorial Board Member and a Web Writer for Polymer Chemistry. Since January 2019, she joined the Materials Department of ETH Zurich as an Assistant Professor to establish her independent research group.