In a recent talk at the Physical Aspects of Polymer Science conference in the UK, Olli Ikkala discussed his work looking at the self-assembly of polymers and biopolymers.

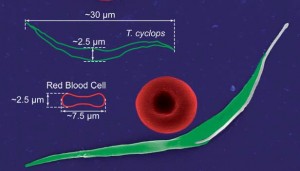

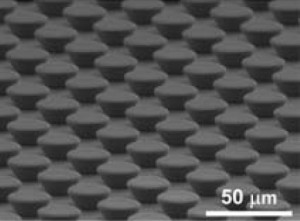

The self-assembly of polymers is a powerful tool for creating or increasing the functionality of a material. Several different functionalities can often be combined in one material, which may also respond to external stimuli. The scale of the pattern required determines the material that should be used. For example surfactants and amphiphiles self-assemble with patterns on the 1-10nm scale, block copolymers on the 10-100nm scale and colloidal platelets or nanofibres form patterns >100nm. Examples of self-assembled functional materials include tuneable optically active materials, electrically conducting materials and porous materials for use as filters or catalysis templates.

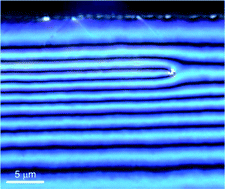

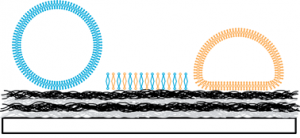

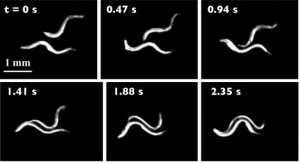

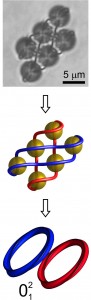

But what if we want to do something more fancy and use biological materials to form structures? This is exactly what Ikkala has been doing, using nature as his inspiration. Examples in his talk included the self-assembly of diblock copolypeptides to form ‘woodpile’ like structures with well-defined lamellae spacing’s. Also discussed was the formation and assembly of cellulose nanofibres to form mechanically robust macrofibres. This was done via a wet extrusion process. The resulting materials have excellent mechanical properties. Using these nanocellulose fibres to form aerogels and coating with titania dioxide results in materials with excellent oil absorbency. This was demonstrated in a nice video. Since the materials float on water and only absorb oil (no water), the materials could potentially be used to clean up oil spills.

Ikkala is also interested in using nanoclays to produce artificial nacre. The replication of nacre in the lab often involves time consuming, complex, energy intensive processes. The use of nanoclays enables lightweight nacre-mimetic films to be created in a roll-to-roll process. These materials have good strength and are very good heat shields. In a video played by Ikkala it was seen that a few mm of the nanoclay nacre was sufficient to protect silk, held on the other side, from damage by a 3000°C (?) heat torch. According to Ikkala: nanoclays are a “good approach to mimicking nacre, but the [material design] is not yet complete”. They do however “know exactly what they need to do” to iron out the problems.

Other work by Olli Ikkala, which may be of interested to Soft Matter readers includes:

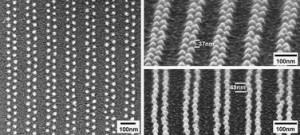

Controlled growth of silver nanoparticle arrays guided by a self-assembled polymer-peptide conjugate, Soft Matter (2010).

Long and entangled native cellulose I nanofibres allow flexible aerogels and hierarchically porous templates for functionalities, Soft Matter (2008).

Tailoring of the hierarchical structure within electrospun fibres due to supramolecular comb-coil block copolymers, Soft Matter (2007).