This month sees the following articles in Lab on a Chip that are in the top ten most accessed July – September:-

Detection of waterborne parasites using field-portable and cost-effective lensfree microscopy

Onur Mudanyali, Cetin Oztoprak, Derek Tseng, Anthony Erlinger and Aydogan Ozcan

Lab Chip, 2010,10, 2419-2423

DOI: 10.1039/C004829A

Electrowetting-based actuation of droplets for integrated microfluidics

M. G. Pollack, A. D. Shenderov and R. B. Fair

Lab Chip, 2002,2, 96-101

DOI: 10.1039/B110474H

High-purity and label-free isolation of circulating tumor cells (CTCs) in a microfluidic platform by using optically-induced-dielectrophoretic (ODEP) force

Song-Bin Huang, Min-Hsien Wu, Yen-Heng Lin, Chia-Hsun Hsieh, Chih-Liang Yang, Hung-Chih Lin, Ching-Ping Tseng and Gwo-Bin Lee

Lab Chip, 2013,13, 1371-1383

DOI: 10.1039/C3LC41256C

Paper-based microfluidic point-of-care diagnostic devices

Ali Kemal Yetisen, Muhammad Safwan Akram and Christopher R. Lowe

Lab Chip, 2013,13, 2210-2251

DOI: 10.1039/C3LC50169H

Recent advances in microfluidics combined with mass spectrometry: technologies and applications

Dan Gao, Hongxia Liu, Yuyang Jiang and Jin-Ming Lin

Lab Chip, 2013,13, 3309-3322

DOI: 10.1039/c3lc50449b

Recent advances in particle and droplet manipulation for lab-on-a-chip devices based on surface acoustic waves

Zhuochen Wang and Jiang Zhe

Lab Chip, 2011,11, 1280-1285

DOI: 10.1039/C0lC00527D

Droplet microfluidics

Shia-Yen Teh, Robert Lin, Lung-Hsin Hung and Abraham P. Lee

Lab Chip, 2008,8, 198-220

DOI: 10.1039/B715524G

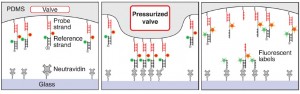

Probing cell–cell communication with microfluidic devices

Feng Guo, Jarrod B. French, Peng Li, Hong Zhao, Chung Yu Chan, James R. Fick, Stephen J. Benkovic and Tony Jun Huang

Lab Chip, 2013,13, 3152-3162

DOI: 10.1039/C3LC90067C

Albumin testing in urine using a smart-phone

Ahmet F. Coskun, Richie Nagi, Kayvon Sadeghi, Stephen Phillips and Aydogan Ozcan

Lab Chip, 2013,13, 4231-4238

DOI: 10.1039/C3LC50785H

Clear castable polyurethane elastomer for fabrication of microfluidic devices

Karel Domansky, Daniel C. Leslie, James McKinney, Jacob P. Fraser, Josiah D. Sliz, Tiama Hamkins-Indik, Geraldine A. Hamilton, Anthony Bahinski and Donald E. Ingber

Lab Chip, 2013,13, 3956-3964

DOI: 10.1039/C3LC50558H

Why not take a look at the articles today and blog your thoughts and comments below.

Fancy submitting an article to Lab on a Chip? Then why not submit to us today or alternatively email us your suggestions.