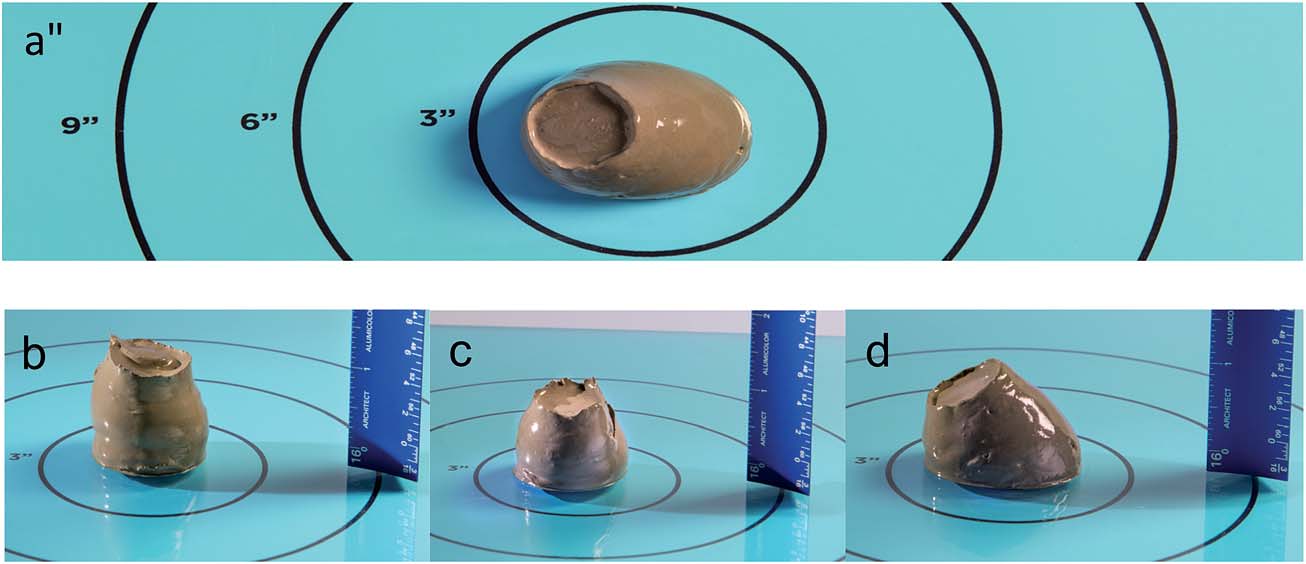

Superplasticisers are a class of materials used to inhibit aggregation in hydraulic cement, improving workability and reducing water requirements without sacrificing strength. Most superplasticisers are anionic polymer dispersants, such as the leading commercial products, polycarboxylate ethers. A low-cost alternative to this class of materials is provided by the plant-derived biopolymer lignin. Lignin is an abundant biopolymer as it is found in most land plants as a component in cell walls. However, Lignin-based substances are poorly performing plasticisers and attempts to significantly improve their properties by copolymerisation with synthetic monomers have thus far been relatively unsuccessful.

In this recent report Gupta et al. provide an alternate approach to the production of high-performance superplasticisers by utilising lignin as a macroinitiator for a reverse addition-fragmentation chain-transfer (RAFT) polymerisation. RAFT is a controlled radical polymerisation technique, which affords good control of molecular weight and polydispersity. Acrylamide was polymerised from the lignin surface in order to create grafted architectures composed of lignin cores with synthetic polyacrylamide coronas. It is found that the lignin compounds synthesised using RAFT polymerisation are more efficient superplasticisers than those prepared by free radical polymerisation, due to their unique polymer-grafted architecture.

The resulting lignin based materials reduced the yield stress of cement paste to similar levels as a leading commercial superplasticiser at concentrations ten-fold lower. These compounds have excellent potential as next-generation admixtures for hydraulic cement, with further work needed to clarify optimal grafting density and length of coronal polymer-chains.

To findout more read the full article below:

Molecular Architecture Requirements for Polymer-Grafted Lignin Superplasticizers by Chetali Gupta, Madeline J. Sverdlove and Newell R. Washburn, Soft Matter, 2015, Advance Article. DOI: 10.1039/C4SM02675F

This post was written by web writer Rob Woodward. Rob is currently based in Imperial College London working in the Polymer and Composite Engineering (PaCE) group. Rob has a background in both responsive polymeric surfactants and microporous organic polymers for carbon capture and storage.