US scientists have devised a method of generating 3D structures from flat surfaces by printing patterns onto a polymeric children’s toy and letting an IR heat lamp do the rest.

Polymers that are responsive to an applied stimulus have attracted interest in a variety of areas, and polymers that self-fold have potential applications in packaging, mechanical actuation, sensors and drug delivery.

Shape memory polymers, which return to a pre-programmed form upon a threshold temperature or other stimulus, suffer from limited movement and require complex syntheses, as the parts of the polymer that respond to the synthesis must be chemically different to the panels that move. This new technique, however, uses conventional black printer ink to print a hinge onto a cheap and readily available pre-stressed polystyrene polymer. Interested to know more? Read the full article in Chemistry World here…

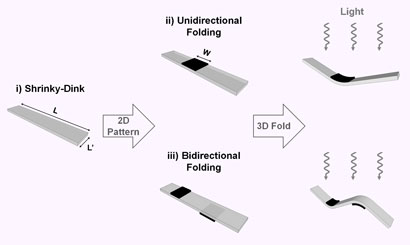

(i) A Shrinky Dink; (ii) unidirectional folding via absorption of light by black ink patterned on one side of the Shrinky Dink; (iii) bidirectional folding due to ink on both sides of the Shrinky Dink. Owing to effective light absorption by the ink, the polymer under the black ink heats up faster than the rest of the polymer

Self-folding of polymer sheets using local light absorption

Y Liu, J K Boyles, J Genzer and M Dickey

Soft Matter, 2011

DOI: 10.1039/c1sm06564e

To keep up-to-date with all the latest research, sign up for the Soft Matter e-Alert or RSS feeds or follow Soft Matter on Twitter or Facebook