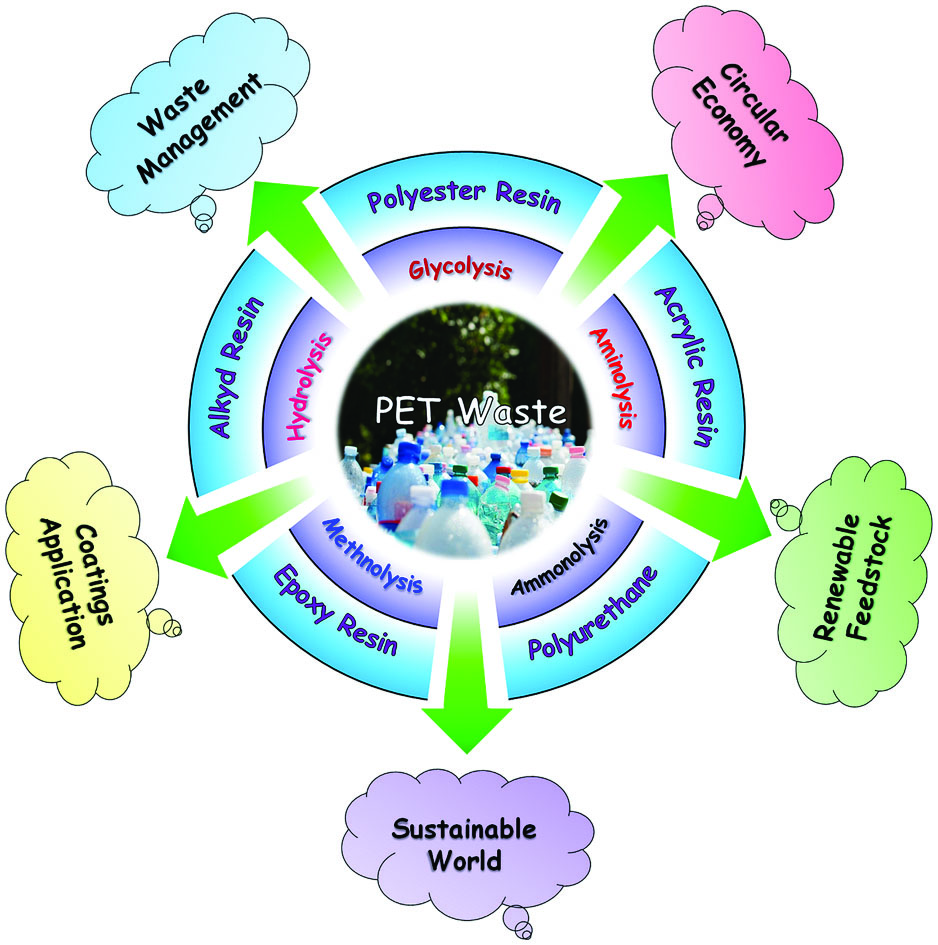

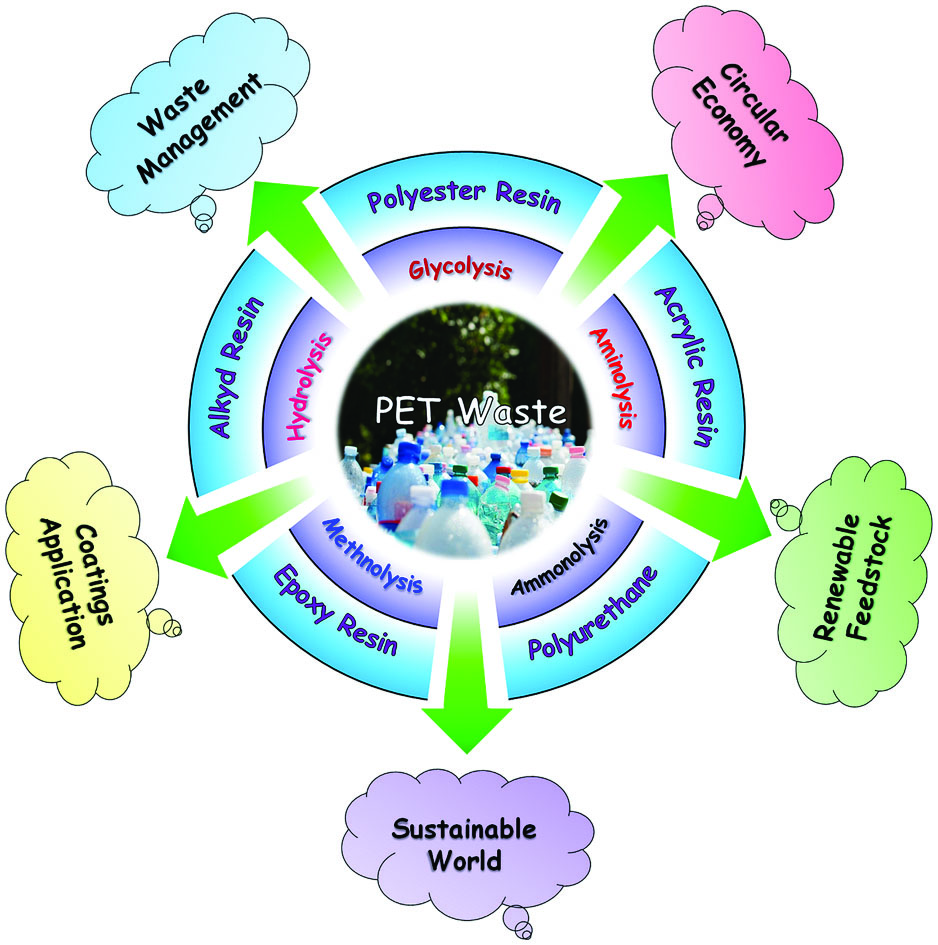

Recent advances in chemical recycling of polyethylene terephthalate waste into value added products for sustainable coating solutions – hope vs. hype

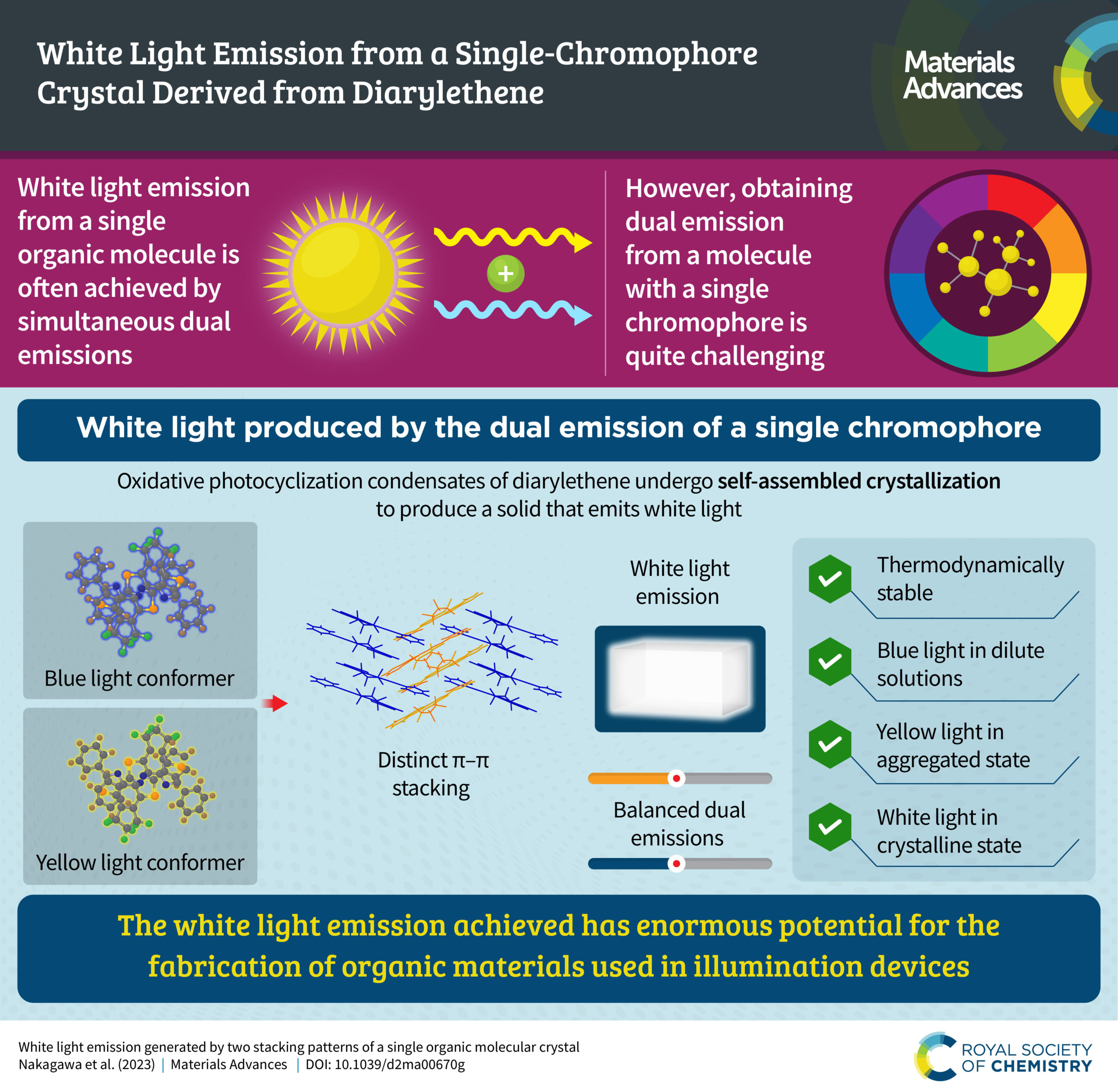

Materials Advances publishes review articles on topics across materials science, which are open access and free to read. To celebrate our excellent review articles, we asked the authors of some of our most well-received review articles to discuss their work in more detail.

In this post, we share insights from our interview with Krishanu Ghosal and learn more about the authors of recently published paper Recent advances in chemical recycling of polyethylene terephthalate waste into value added products for sustainable coating solutions – hope vs. hype.

Insights from the authors of a highly cited Materials Advances review article

What aspect of your research are you most excited about at the moment?

“In this polymer age, the unprecedented escalation in the production, consumption, and disposal of post-consumer polymeric waste materials has become a critical environmental concern of paramount importance. According to a World Bank report, in 2016, the global production of plastic waste reached a staggering 242 million tonnes, constituting approximately 12% of the total solid waste generated worldwide. Historically, a significant portion of this plastic waste has been managed through methods such as landfills or incineration.

To address this escalating issue, researchers are now concentrating on the 3R (reduce, recycle, and reuse) concept of plastic products. Currently, I am specifically working on the recycling of plastic waste into value-added chemicals, which can serve as raw materials or intermediates for the creation of new materials, including novel biodegradable polymers. More precisely, my work involves developing new classes of biodegradable polymers derived from recycled polymeric materials waste focusing on biomedical and coatings applications.”

What do you find most challenging about your research?

“I feel that, the most challenging part about my research is translation of technology from lab to commercial scale. It’s common for reactions, processes, or technologies that prove effective in a lab setting to encounter significant drawbacks when implemented on an industrial scale. This challenge is particularly pronounced in the field of polymer recycling, where there has been a surge in research articles. Unfortunately, only a handful of these innovations make it to commercialization while maintaining socio-economic viability.

A noteworthy observation is the disparity between the promising laboratory results and the practical hurdles faced during industrial implementation. A recurring issue is the elevated cost of recycled raw materials compared to readily available fresh raw materials in the market, which diminishes the feasibility of recycling initiatives. Additionally, it’s imperative to consider the environmental impact of the recycling process. An ideal recycling method should not only be economically viable but also environmentally sustainable, ensuring a carbon-neutral or even negative footprint, while avoiding the generation of harmful chemicals throughout the entire process.”

What does it mean to you to have a highly cited review article?

“Receiving acknowledgment from peers in the same field is a truly gratifying experience for any researcher. It not only validates the dedication and effort invested in one’s work but also fosters a sense of professional camaraderie and shared appreciation within the research community.”

How do you feel about Materials Advances as a place to publish research on this topic?

“All of the journals of Royal Society of Chemistry’s Materials family are highly reputed among materials researchers. The Materials Advances platform offers a unique opportunity for researchers to showcase their latest findings in the dynamic field of materials science. Publishing in Materials Advances experience is really amazing. Additionally, because Materials Advances is an OA journal, the reach of the journal is broader, which attracts many researchers working in different fields of materials to read and publish in Materials Advances.”

What is one piece of career-related advice or wisdom that you would like to share with early career scientists?

“I feel that, early career researchers should choose problem statements wisely. To address these challenges, early career scientists should take the initiative and independently formulate solutions for their chosen problem statements. Engaging in discussions with fellow researchers and colleagues regarding the problem statement and potential solutions serves as a valuable process for refining and sharpening the proposed solution. This collaborative process not only hones their problem-solving skills but also cultivates critical thinking, fostering the development of well-rounded and innovative researchers.

Furthermore, I would recommend that early career scientists actively explore opportunities to translate their research into commercial applications. This initiative not only maximizes the societal impact of their work but also exposes them to the complexities and practicalities of taking scientific innovations from the lab to the market. By bridging the gap between research and commercialization, these scientists can bring out the true potential of their findings to the broader public, making a meaningful difference in the real world.”

Meet the authors

Dr Krishanu Ghosal is currently a Post-Doctoral Fellow at the Wolfson Faculty of Chemical Engineering, Technion-Israel Institute of Technology. Before joining Technion he worked as an Assistant Technical Manager in Shalimar Paints Ltd. He did his Ph.D at the Department of Polymer Science and Technology, University of Calcutta, with a thesis titled “Synthesis of biopolymers from recycled plastic waste and natural resources for tissue engineering applications”. He obtained his B.Sc. in Industrial Chemistry and M.Sc. in Applied Chemistry from Ramakrishna Mission Vidyamandira, Howrah, India. During his B.Sc. and M.Sc., he was actively involved in various research activities as well as industrial training. During an M.Sc. summer internship, he worked under Professor T P Radhakrishnan, School of Chemistry, University of Hyderabad. There he worked on a project titled “Synthesis of ultrathin film based on poly-N-octadecylaniline based gold and silver nanoparticles using the air-solution interface”. He also worked under the guidance of Dr Atanu Bhattacharya at IISc Bangalore, completing his master’s thesis titled “Ground state decomposition mechanism of metal contained nitramine molecule”. His research interests include several diverse fields including synthesis of novel polymers, recycling of polymeric materials into value-added products, synthesis of nanomaterials and their biomedical applications, green chemistry etc. |

Mr Chinmaya Nayak is currently serving as the Head of Industrial R&D in Shalimar Paints Limited. Previously he worked as a Senior Development Manager in R&D at Berger Paints India Ltd, Kolkata. He received his M.Sc. degree in Chemistry from Delhi University and his M.Tech. (Corrosion Science & Technology) from NIT-Durgapur. He has 24 years of experience in the paint industry. As a seasoned R&D professional in the paint industry, he has designed and commercialized more than 2000 formulations. Additionally, he has trained more than 100 professionals in the field of paint technology. He has been a part of numerous technical events and conferences. In addition to that, he has been actively involved in the presentation and publication of technical papers. |

We congratulate the authors on their impactful work and wish them success in their future academic research!