Responses provided by Juliane Hefel, PPG general manager of specialty coatings & materials and Janice Mahon, Universal Display Corporation (UDC), senior vice president of technology commercialization and general manager, Commercial Sales Business.

Responses provided by Juliane Hefel, PPG general manager of specialty coatings & materials and Janice Mahon, Universal Display Corporation (UDC), senior vice president of technology commercialization and general manager, Commercial Sales Business.

What relevance does this industry have to the readers of Materials Advances?

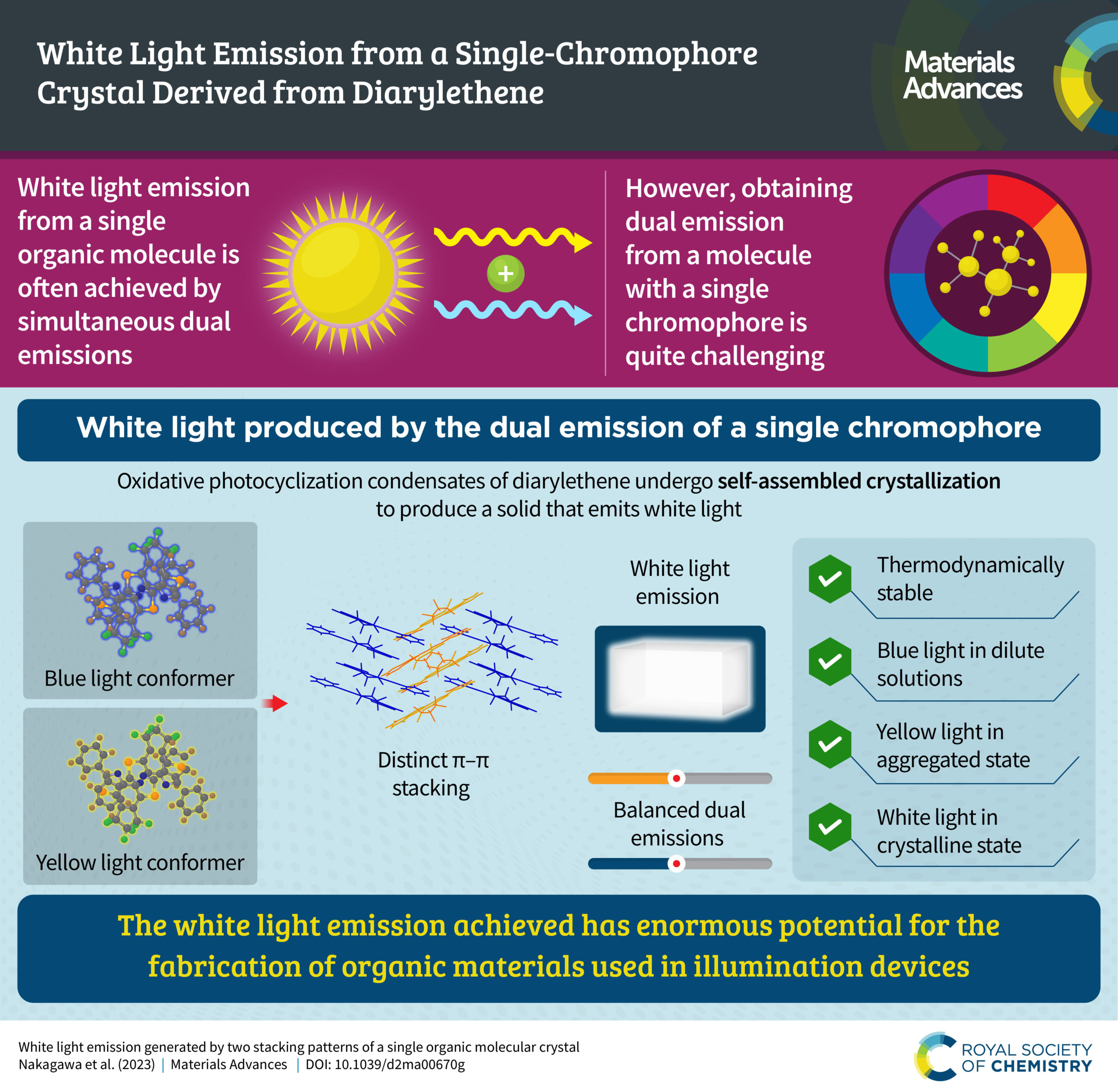

Both: Complex small molecule organic and organometallic materials manufacturing holds immense relevance for researchers, particularly concerning the advances organic chemistry has made in the electronics industry and its potential to transform our daily lives.

Through the years, organic molecules have evolved to play an increasingly crucial role in enabling miniaturization and enhancing connectivity of electronics, such as OLEDs, organic photovoltaic cells (OPVs), and organic field-effect transistors (OFETs), and other industries that rely on material science.

OLEDs and other small organic molecule-based devices can be lightweight and flexible, enabling ultra-thin, bendable, and lightweight electronic products, including wearable devices, flexible displays, and electronic textiles.

One of the most significant advantages of small molecule organic materials in electronics is its sustainability as they can be developed to be incredibly energy efficient, potentially reducing the reliance on fossil fuels and minimizing environmental impact.

The interdisciplinary nature of materials science opens up exciting opportunities. From the lab to the plant, researchers and scientists working in the OLED industry, and manufacturing sector in general, collaborate in the design of disruptive advancements that create next-generation materials. With the potential to reshape the future of electronics and contribute to a more sustainable world, organic molecule manufacturing in general presents an exciting and impactful avenue in the field of chemistry and a doorway to diverse and high-tech career paths

What are your roles at PPG and UDC, respectively?

Juliane: I’m the general manager of PPG’s Specialty Coatings and Materials business. In my role, I deliver strategic and operational leadership to the business which creates solutions that enhance the surfaces and materials critical in our daily lives. Our products help secure the personal information in passports and ID cards to combat fraud, make our car tires safer and more fuel-efficient, and provide monomers, coatings and photochromic dyes in eyeglass lenses that improve and enhance your vision. We also produce energy-efficient organic light-emitting diode (OLED) materials to create the vibrant images you see on your TV, smartphone and other consumer electronics through our partnership with Universal Display Corporation (UDC). Together, we married UDC’s innovative technologies and materials with PPG’s expertise with ultra-high-purity organic material manufacturing, leading to breakthroughs in the high-efficiency phosphorescent OLEDs that fuel the display industry.

Janice: I’m the senior vice president of Technology Commercialization and general manager of Commercial Sales Business at Universal Display Corporation. I lead the transition of our high-performing, energy-efficient phosphorescent OLED (PHOLED) materials from our R&D labs in Ewing, New Jersey to the worldwide commercial market. I’m responsible for the manufacture, quality assurance and delivery of UDC’s PHOLED materials to the world’s leading display and lighting panel makers. It has been more than 20 years since I helped form the successful partnership between UDC and PPG. Through these two-plus decades, PPG and UDC have established robust systems that drive efficiency, reliability, and customer satisfaction. This unwavering commitment to assured supply and quality are critical to our strong leadership position in the OLED ecosystem.

What aspect of your work are you most excited about now and what do you find most challenging?

Both: Keeping up with the speed of electronic evolution presents an exciting opportunity as we look to the future. As consumer electronics technology and requirements evolve, so must our production of OLED emitters. The development of new and next-generation devices moves fast, and it takes agility and ingenuity to keep pace.

The equipment used to produce and test the products, combined with PPG and UDC’s 20-plus years of know-how, allows both companies to offer next-generation products smartly and respond to customer requests rapidly. Through this collaboration and as we experience the quick pace of product evolution in consumer electronics, PPG and UDC look forward to product launches that deliver increasingly sustainable manufacturing practices.

We’re also excited about the real power savings advantages that phosphorescent OLED technology offers. When used in smartphones, PHOLED materials are estimated to save more than 860,000 metric tons of carbon dioxide equivalent each year. Based on EPA’s calculator, this is comparable to the carbon sequestered by more than 14 million tree seedlings grown for ten years.

In May, PPG and UDC officially opened a new state-of-the-art OLED manufacturing facility in Shannon, Ireland. The site is expected to double the production capacity and diversify the worldwide manufacturing footprint for UDC’s energy-efficient phosphorescent OLED emissive materials to support the rapidly growing consumer electronics and display marketplaces.

Increasing global capacity through retrofitting an existing manufacturing plant in Shannon, we were able to pivot quickly to meet increasing customer needs now and into the future.

How are the materials specifications evolving in consumer electronics?

How are the materials specifications evolving in consumer electronics?

Both: UDC’s phosphorescent OLED molecules are designed to convert electricity to photons of light efficiently. Like with semiconductors, there is a requirement for extreme purity to ensure optimal function of the compound in an OLED device.

Agility is another must, as consumer electronic specifications continue to evolve. We must adopt the latest technology to make materials and monitor quality. Our focus on increasing sustainability of our manufacturing processes along with changing policies and restrictions also require innovative approaches. Flexibility is necessary to meet the exacting requirements as they continue to shift.

What do you see as the next big challenge to overcome in the area? (both from the consumer electronics and high-purity large scale manufacturing)

Juliane: We work with our customers and suppliers to solve problems with each new material and collaborate with partners as a key to success. From a manufacturing standpoint, we continuously evaluate how best to stay ahead of quickly changing customer requirements and needs.

With UDC, we’re actively delivering leading-edge phosphorescent PHOLED materials with leading-edge quality. Like pharmaceuticals, manufacturing phosphorescent emitters for OLEDs is a complex process to get to the precise purity level needed for materials that ultimately convert electricity into light.

Identifying and creating an environment to effectively manufacture this material requires extensive technical manufacturing know-how and will face continual evolution.

Janice: The evolution of consumer electronics continues at a rapid pace, driven by ongoing technological breakthroughs and changing consumer expectations. Our team of scientists, engineers and technicians are continuously discovering, developing and delivering next-generation phosphorescent OLED materials to meet the ever-changing and ever-evolving specifications for energy efficiency, operational lifetime and color gamut. Quickly scaling these materials from lab to high volume commercial market quantities and quality can be challenging, however, PPG and UDC’s long-standing commitment to excellence, cost-effectiveness and delivery reinforces our position as a trusted partner to the OLED industry.

Can you share one piece of career-related advice for early career scientists?

Juliane: Be transparent and hold yourself and others accountable for making progress and reaching goals. This builds trust in you as individual, as team player and your capabilities. I can’t emphasize enough the value of teamwork in accountability. Collective decision-making and goal agreement allows for bolder choices and calculated risk-taking.

I also always encourage a mindset that embraces change. Tap into others who also welcome change to create a multiplier effect. This type of engagement is key to developing the future. When we understand and anticipate the needs of partners and customers, we can accelerate change and becoming future-ready solution creators. With the integration of advanced technology like AI becoming increasingly important in the world, scientists should be ready for changing challenges.

Janice: Prioritize integrity in your actions and decisions, as it fosters strong relationships, inspires trust, and establishes a reputation of consistent and dependable character that will benefit your career in the long run. UDC’s core value of integrity has created a corporate culture that thrives, takes risks, and innovates. It has also been critical in establishing and solidifying our long-standing partnerships and reinforcing our position as a pioneering leader in the OLED ecosystem. In both personal and professional settings, integrity and trust are crucial for establishing credibility, cultivating healthy relationships, and achieving shared goals.