Green Chemistry is proud to present the Green Chemistry Emerging Investigators Series, showcasing work being conducted by Emerging Investigators. This collection aims to highlight the excellent research being carried out by researchers in the early stages of their independent career from across the breadth of green chemistry. For more information about this series, click here

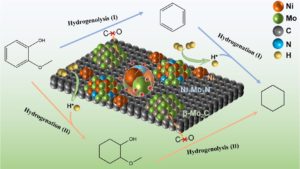

Among the contributions to this series is a Paper entitled Complementary acid site mechanisms in hydrogen-free polyethylene upcycling: elucidating the distinct roles of Brønsted and Lewis sites in Ce-modified zeolites (DOI: 10.1039/D5GC01799H).

Read our interview with the corresponding author Prof. Insoo Ro below.

How would you set this article in a wider context?

Most advanced plastic-to-fuel methods still depend on fossil-derived hydrogen. By clarifying how Brønsted and strong Lewis acid sites can work together to use the plastic’s own hydrogen, our study outlines a hydrogen-free route that could lower cost and carbon intensity and offers a design framework extendable to other difficult plastics.

What is the motivation behind this work?

We aimed to remove the hidden hydrogen and noble-metal costs from polyolefin upcycling and answer a mechanistic question: can Lewis acid sites actively drive hydrogen transfer under hydrogen-free conditions? Our results indicate they can—and quantify their impact.

What aspects of this work are you most excited about at the moment and what do you find most challenging about it?

I’m excited that we can tune the acid-site balance to push selectivity to valuable liquids while suppressing coke. Key challenges now are scale-up in continuous flow, handling mixed/contaminated waste streams, and maintaining site proximity and strength over long times on stream.

What is the next step? What work is planned?

We will (i) Translate the chemistry into continuous reactors and regeneration protocols; (ii) optimize site proximity and mesostructure to stabilize strong Lewis sites; (iii) extend hydrogen-free concepts to mixed polyolefins and difficult feeds; and (iv) complete techno-economic and life-cycle assessments with partners.

Please describe your journey to becoming an independent researcher

I received my B.S. from Rice University and Ph.D. from the University of Wisconsin–Madison, followed by postdoctoral research at UC Santa Barbara. I started my independent group in 2020 and am now an Associate Professor at Korea University.

Can you share one piece of career-related advice or wisdom with other early career scientists?

Write your “mechanism of impact” as early as you write your experimental plan—what changes if you’re right, and who cares. It keeps projects focused, eases collaboration, and helps you avoid distracting side paths.

Why did you choose to publish in Green Chemistry?

The journal’s mission aligns with our goal of lowering the carbon and resource footprints of plastics upcycling. Green Chemistry also reaches a community where mechanistic catalysis and sustainability meet, and the Emerging Investigators Series offers timely visibility with rigorous peer review.

Meet the author

Angelo Scopano

Angelo Scopano