Watching paint dry can be fun and rather surprising! David Fairhurst from Nottingham Trent University has been looking at the structures that form when polymer droplets are left to dry.

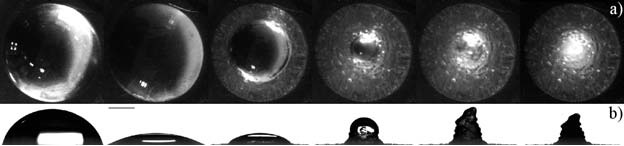

Small droplets of aqueous poly(ethylene oxide) (PEO) are placed onto glass substrates and the water allowed to evaporate. Initially, pinned drying is observed; the radius of the droplet remains fixed while the height and contact angle decrease. When the polymer concentration, at the contact line, reaches the saturation concentration PEO starts to precipitate. A semi-crystalline solid forms and the contact line starts to recede. As the droplet dewets polymer is continually deposited at the contact line. The solid layer pushes the droplet back further in an autophobic like manner. This process continues until the height of the droplet starts to increase. Now the PEO is deposited on top of itself. The edge of the ever shrinking droplet is lifted and a conical structure forms. Any remaining water evaporates, leaving behind a semi-crystalline PEO tower.

The structure which forms is dependent on a number of parameters including: the initial polymer concentration in the drop, the relative humidity, temperature and pressure under which the droplet is dried and the contact angle of the drop when it is first deposited. The results, recently published in Soft Matter, are explained in terms of polymer flow within the drop due to evaporative flux and the diffusion of the polymer. Diffusion drives the homogenisation of the polymer within the droplet, while the evaporative flux induces an outward flow of the polymer. If the evaporative flux dominates, deposition at the contact line occurs and a pillar structure forms.

Various videos of the drying droplets can be found here and are well worth a look. Fairhurst suggested in his talk that these solutions could be used as potential antidrip paints. When left to dry on a slanted substrate the pillars form uphill of the initial drop. Missing corners when painting could be a thing of the past.

K. Baldwin, M.Granjard, D. I. Willmer, K. Sefiane and D. J. Fairhurst, Drying and deposition of poly(ethylene oxide) droplets determined by Péclet number, Soft Matter, 2011, 7, 7819-7826