Developing efficient crop fertilisation has become an ever-growing concern given the increasing demand for global food production. Slow-release fertilisers have been developed as a strategy to increase the efficiency of crop production while minimizing nutrient waste, reducing negative environmental impacts and enhancing crop yield. Mechanisms for controlled nutrient diffusion include semi-soluble or complex forms of the nutrient, slow hydrolysis of water-soluble compounds, and encapsulation of the nutrient within semipermeable or permeable coatings for controlled solubility/release (among many others). While slow-release strategies are promising, technical limitations such as the brittle nature of inorganic coatings and composites or the imperishable nature of synthetic polymer coatings hinder their industrial utility.

In a collaborative study published by Professor Justin Chalker of Flinders University, the group sought to develop an efficient and durable slow-release fertiliser derived from canola oil and elemental sulfur. Sulfur is highly appealing given its low cost, abundance, and that it is a secondary plant nutrient and fungicide. Numerous studies and years of research, however, have demonstrated that a persistent limitation of sulfur-coated fertilizers is their brittle nature. The present study, therefore, focused on converting sulfur to a more durable polymer form to be used as a composite with or encapsulate NPK (nitrogen, phosphorous, and potassium) nutrients.

In a collaborative study published by Professor Justin Chalker of Flinders University, the group sought to develop an efficient and durable slow-release fertiliser derived from canola oil and elemental sulfur. Sulfur is highly appealing given its low cost, abundance, and that it is a secondary plant nutrient and fungicide. Numerous studies and years of research, however, have demonstrated that a persistent limitation of sulfur-coated fertilizers is their brittle nature. The present study, therefore, focused on converting sulfur to a more durable polymer form to be used as a composite with or encapsulate NPK (nitrogen, phosphorous, and potassium) nutrients.

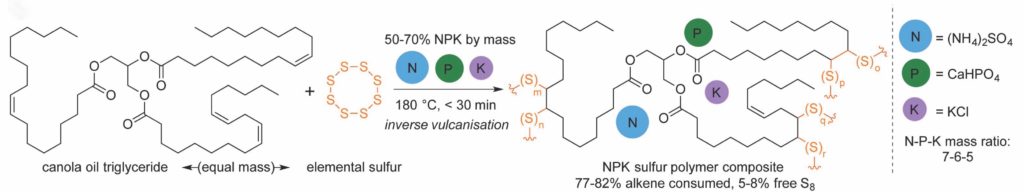

Inverse vulcanisation was used to prepare the sulfur polymer. In this process, elemental sulfur is heated to promote the production of thiyl radicals which can react with an unsaturated small-molecule cross-linker. In this case, canola oil was used as the cross-linker to form a polysulfide polymer capable of encapsulating NPK nutrients.

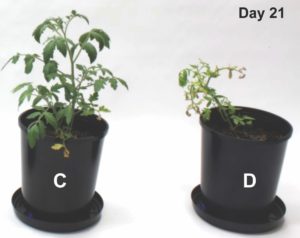

Elution studies in which fertiliser is placed in a soil column and conductivity of the outflow is measured demonstrated the superior capabilities of the sulfur-encapsulated NPK fertiliser in controlling NPK nutrient release relative to free NPK. A small-scale plant growth study also found that plants treated with the composites were significantly healthier and produced more fruit relative to other groups. What’s even more exciting is the fact that the canola oil polysulfide can be made from recycled cooking oil, converting food waste into valuable fertilisers.

With the rising challenge of feeding a rapidly growing population while also mitigating damaging environmental impacts, studies such as this that make significant strides toward efficient and sustainable agricultural practices are more important than ever.

To find out more see:

Sulfur polymer composites as controlled-release fertilisers

Maximilian Mann,

DOI:10.1039/C8OB02130A

Victoria Corless has recently completed her Ph.D. in organic chemistry with Prof. Andrei Yudin at the University of Toronto. Her research is centered on the synthesis of kinetically amphoteric building blocks which offer a versatile platform for the development of chemoselective transformations with particular emphasis on creating novel biologically active molecules. She is passionate about communicating new discoveries to enhance science literacy.