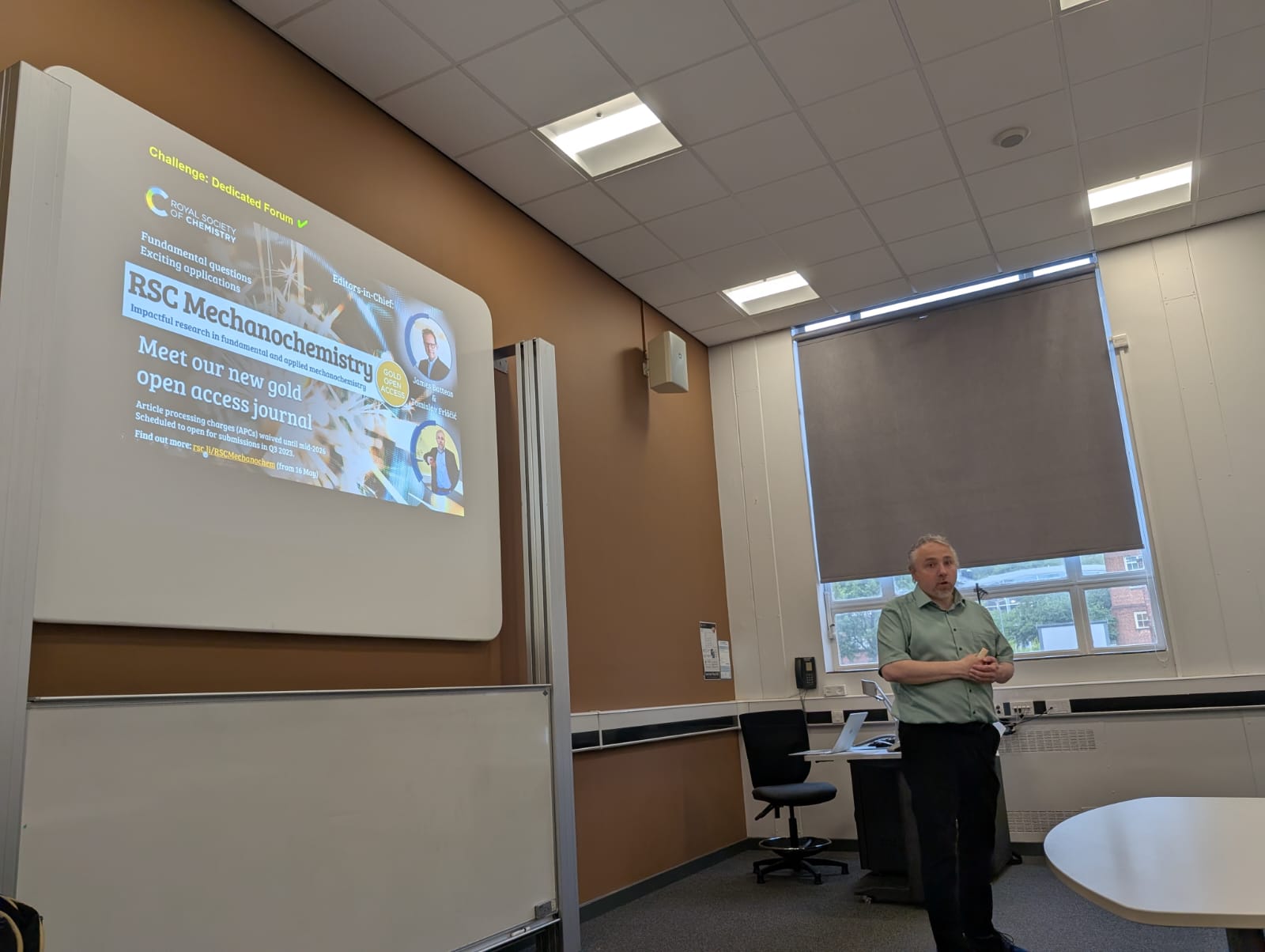

Mechanochemistry is one of the oldest areas of chemistry, but one with significant potential to contribute to a more sustainable future. In 2019 IUPAC named it as one of the ten emerging technologies in chemistry. Like every field, mechanochemistry has its own challenges and opportunities. In our ongoing Editorial series Moving Mechanochemistry Forward, we explore these challenges and opportunities to help inspire researchers and move the field forward.

To date we have published six Editorials:

Moving mechanochemistry forward

James Batteas, Kerstin G. Blank, Evelina Colacino, Franziska Emmerling, Tomislav Friščić, James Mack, Jeffrey Moore, Maria Elena Rivas and Wilfred Tysoe

RSC Mechanochem., 2025, 2, 10-19

Shaken not stirred: procedures in mechanochemical syntheses and how to define them

James Batteas and Tomislav Friščić

RSC Mechanochem., 2025, 2, 175-177

Moving Mechanochemistry Forward: Mechanochemistry and the non-covalent bond

Adam A. L. Michalchuk and Tomislav Friščić

RSC Mechanochem., 2025, 2, 333-335

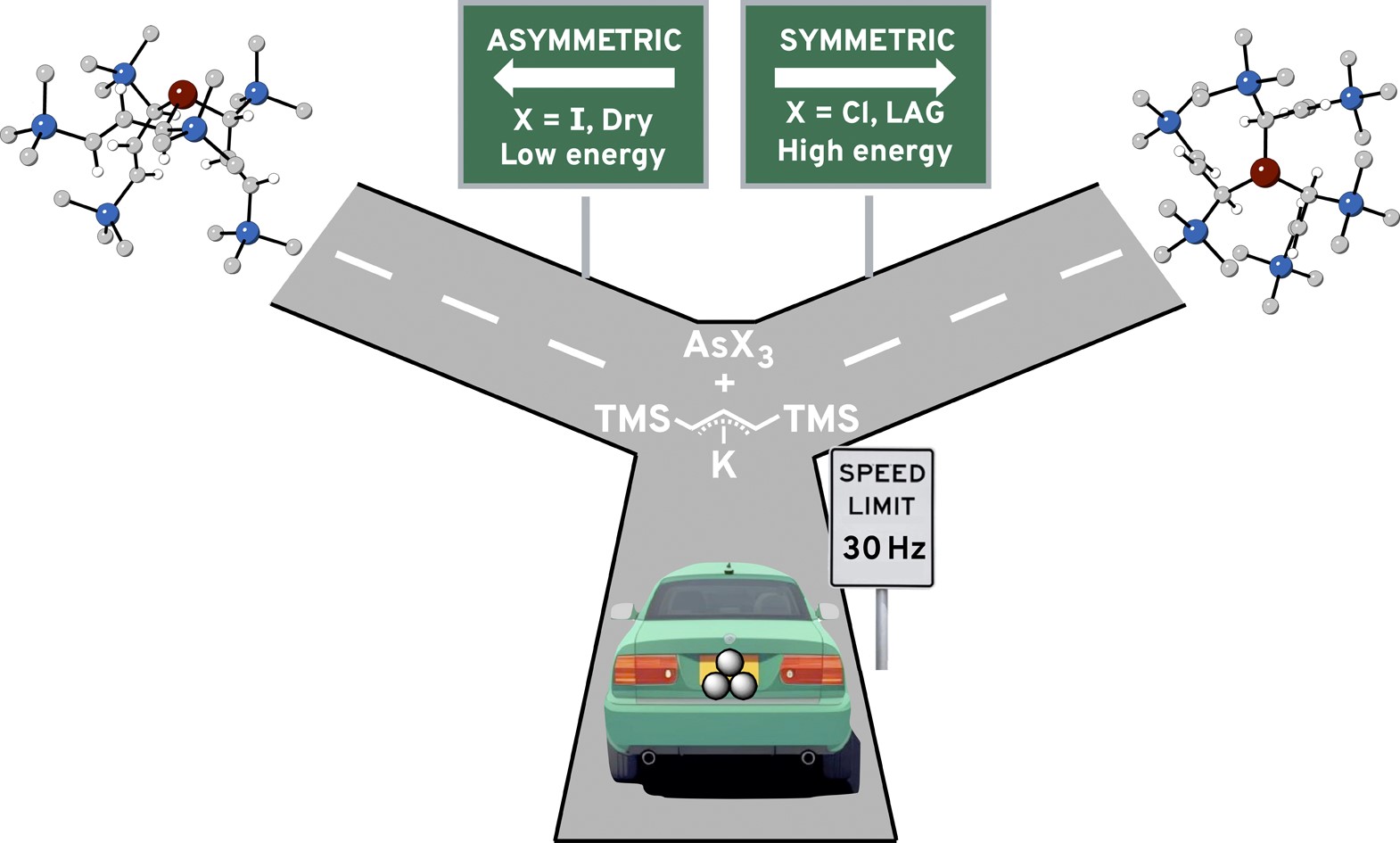

Moving mechanochemistry forward: reimagining inorganic chemistry through mechanochemistry

Felipe García, Mamoru Senna and Vladimir Šepelák

RSC Mechanochem., 2025, 2, 499-502

Moving mechanochemistry forward: programming force-induced responses into macromolecular systems

Kerstin G. Blank and Robert Göstl

RSC Mechanochem., 2025, 2, 627-630

Moving Mechanochemistry Forward: Mechanochemical Polymer Synthesis and Recycling

Jeung Gon Kim

RSC Mechanochem., 2025, Advance Article

|

Are you ready to contribute to the future of mechanochemistry? RSC Mechanochemistry offers you an inclusive and dedicated home for the ideas, scientific language and approaches that cut across the many disciplines mechanochemistry touches. Here we are seeking to build knowledge, as well as foster innovation and discovery at this forefront of chemistry. Whether you are seeking to understand the fundamentals of mechanochemistry, or you are excited by its applications and potential, this journal is for you. All of the content in this journal is gold open access, which means that you can read every article for free, and we are covering all publication costs until mid-2026. |

In my field of soft matter mechanochemistry, we have seen some pretty exciting progress thanks to the development of increasing numbers of synthetic molecules that respond to mechanical force in specific ways. Some key examples are mechanochromic, mechanofluorescent and mechanoluminescent reporters, as well as force-triggered release mechanisms through mechanochemical linkers, reactions kick-started by radicals or mechanocatalysts, mechanochemical switches, and, more recently, artificial catch bonds. What is really exciting is that more and more of these mechanoresponsive systems are working in water, which opens up a lot of possibilities for integrating them with biological systems.

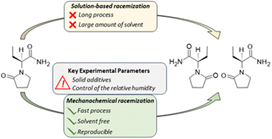

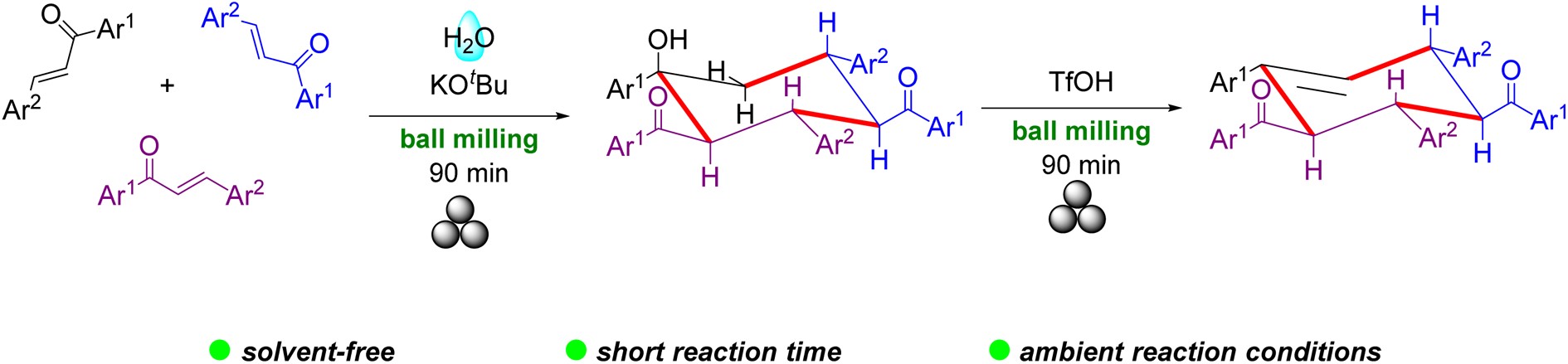

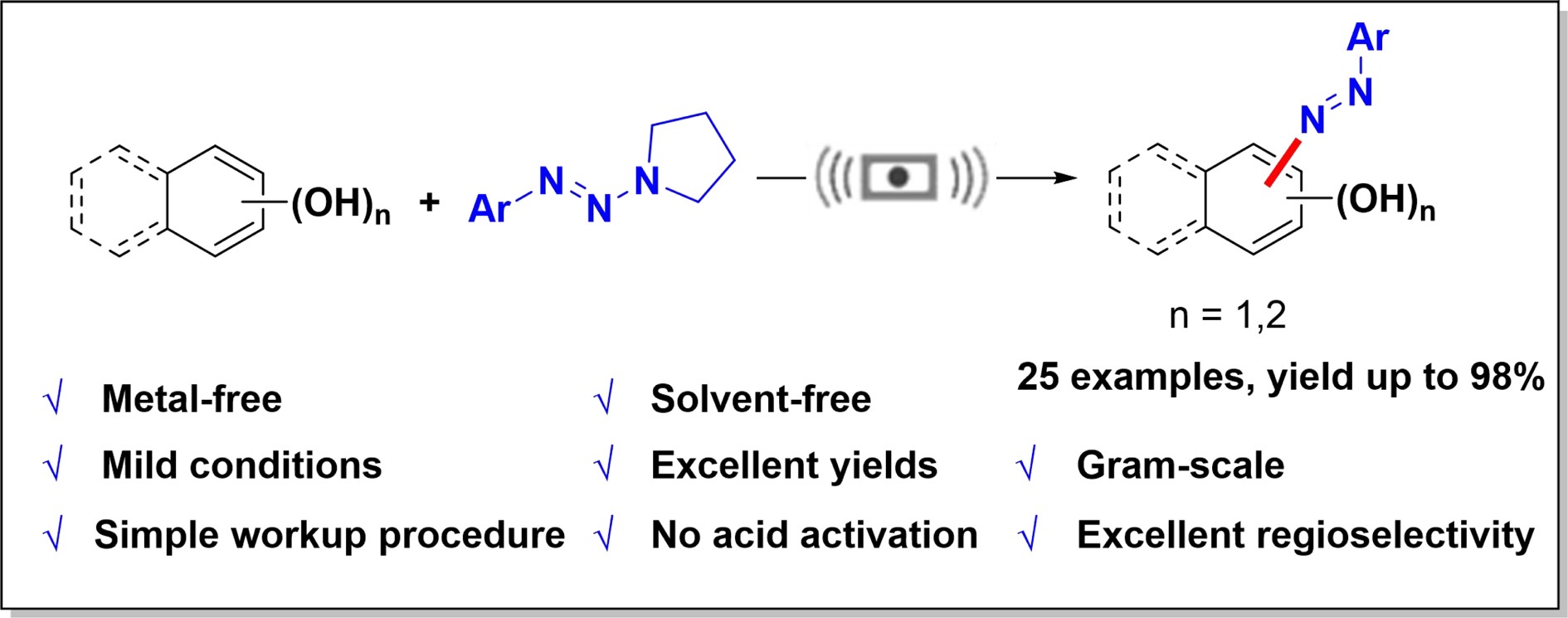

In my field of soft matter mechanochemistry, we have seen some pretty exciting progress thanks to the development of increasing numbers of synthetic molecules that respond to mechanical force in specific ways. Some key examples are mechanochromic, mechanofluorescent and mechanoluminescent reporters, as well as force-triggered release mechanisms through mechanochemical linkers, reactions kick-started by radicals or mechanocatalysts, mechanochemical switches, and, more recently, artificial catch bonds. What is really exciting is that more and more of these mechanoresponsive systems are working in water, which opens up a lot of possibilities for integrating them with biological systems. There is considerable evidence that mechanochemistry is often better than other synthetic methods, especially solution-based ones. Mechanochemistry uses mechanical force to drive chemical reactions, and it can be more efficient, resource-saving and environmentally friendly than traditional solutions.

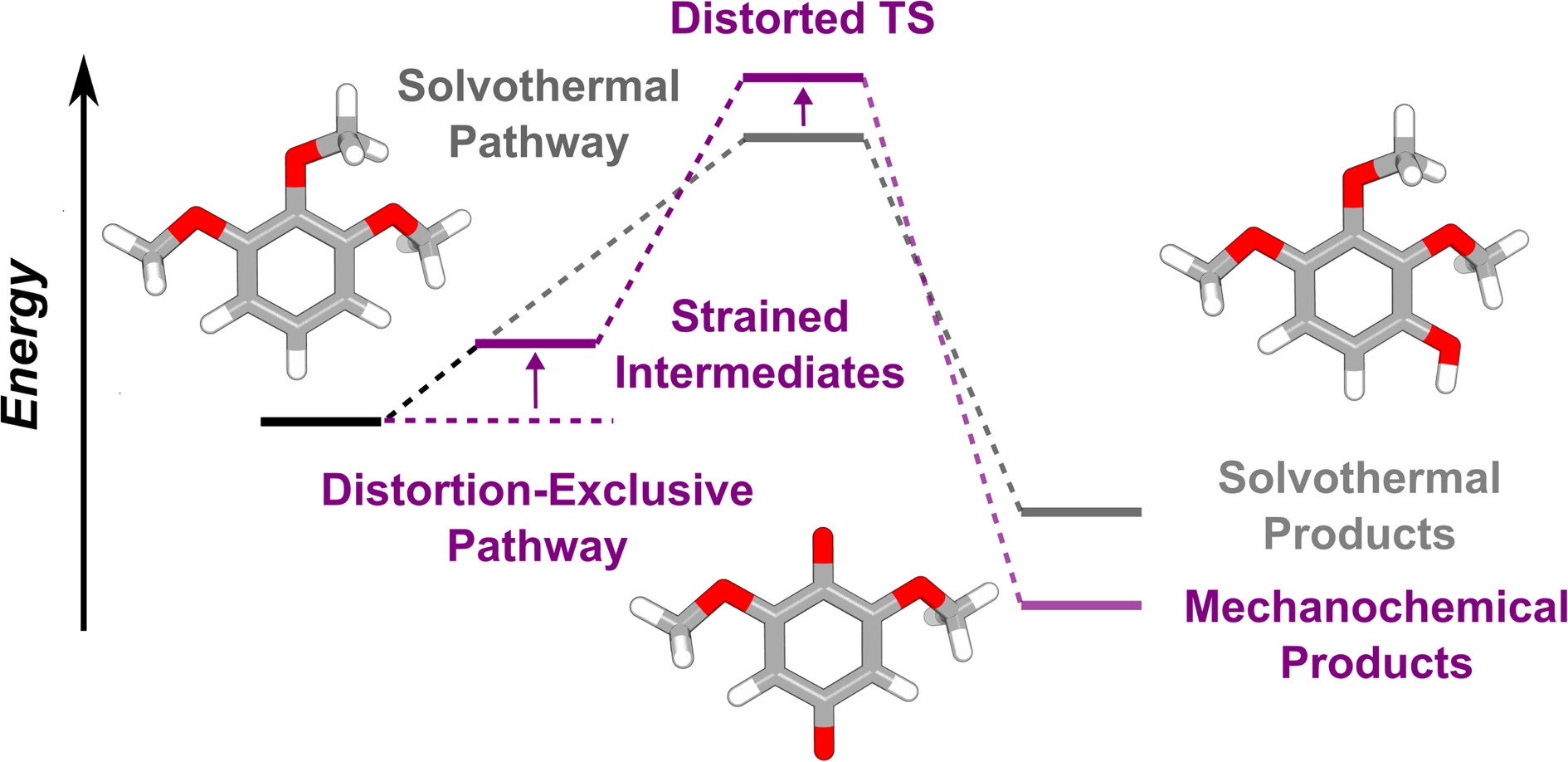

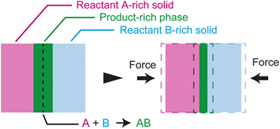

There is considerable evidence that mechanochemistry is often better than other synthetic methods, especially solution-based ones. Mechanochemistry uses mechanical force to drive chemical reactions, and it can be more efficient, resource-saving and environmentally friendly than traditional solutions. Mechanochemistry has always been a paradigm-shifting method for conducting chemical reactions. While we often celebrate groundbreaking ideas in hindsight, they are not always embraced immediately. Consider Galileo Galilei, who faced life imprisonment for endorsing Copernicus’ theory that the Earth orbits the sun. Similarly, Alfred Wegener encountered not just skepticism, but outright hostility for proposing the concept of continental drift, suggesting that continents were once connected and moved across the Earth. One of Wegener’s detractors stated “It is certain the Wegener’s theory was established with a superficial use of scientific methods, ignoring the various fields of geology.” He continued to state “We can only try to keep our distance and beg him not to deal with geology any longer…” Even Einstein’s view of quantum physics was not all that favorable, famously stating “God does not play dice with the Universe” and describing what we now call quantum entanglement as “spooky action at a distance”. These examples highlight not just a mere clash of ideas, but also the hostility directed towards the individuals advocating them.

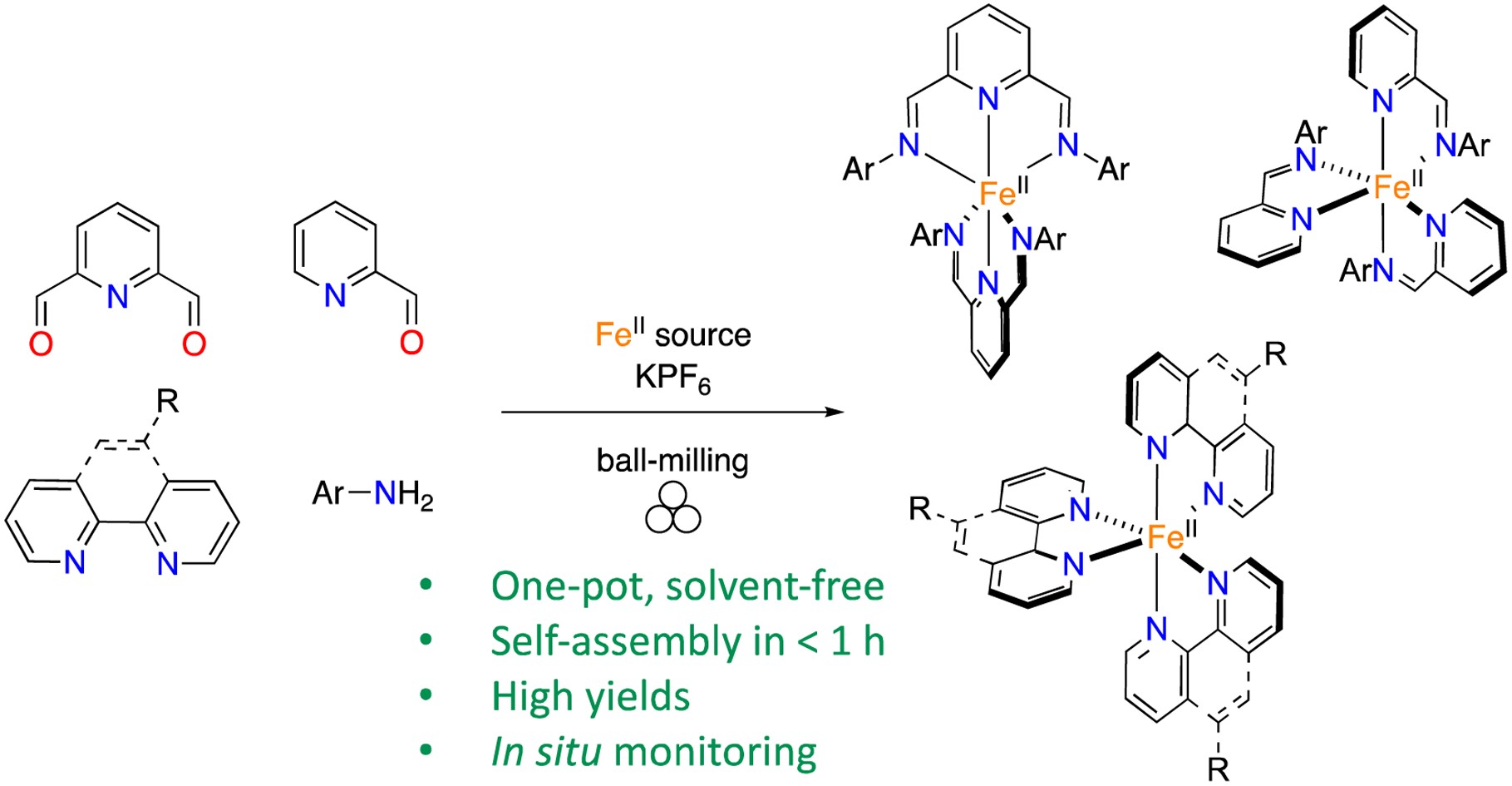

Mechanochemistry has always been a paradigm-shifting method for conducting chemical reactions. While we often celebrate groundbreaking ideas in hindsight, they are not always embraced immediately. Consider Galileo Galilei, who faced life imprisonment for endorsing Copernicus’ theory that the Earth orbits the sun. Similarly, Alfred Wegener encountered not just skepticism, but outright hostility for proposing the concept of continental drift, suggesting that continents were once connected and moved across the Earth. One of Wegener’s detractors stated “It is certain the Wegener’s theory was established with a superficial use of scientific methods, ignoring the various fields of geology.” He continued to state “We can only try to keep our distance and beg him not to deal with geology any longer…” Even Einstein’s view of quantum physics was not all that favorable, famously stating “God does not play dice with the Universe” and describing what we now call quantum entanglement as “spooky action at a distance”. These examples highlight not just a mere clash of ideas, but also the hostility directed towards the individuals advocating them. Mechanochemistry has the potential to revolutionise many industrial applications, such as energy, nanomaterials, and environmental remediation. By using mechanochemistry, our industry can potentially reduce their costs, waste, and environmental impact, while increasing their efficiency, quality, and innovation. Mechanochemistry can also enable the discovery of new compounds and mechanisms that are inaccessible by conventional methods.

Mechanochemistry has the potential to revolutionise many industrial applications, such as energy, nanomaterials, and environmental remediation. By using mechanochemistry, our industry can potentially reduce their costs, waste, and environmental impact, while increasing their efficiency, quality, and innovation. Mechanochemistry can also enable the discovery of new compounds and mechanisms that are inaccessible by conventional methods.