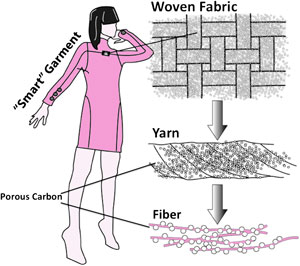

Scientists in the US have taken the first steps towards designing a flexible and lightweight fabric that can act as a power supply for smart garments.

Electronic textiles, or ‘smart’ textiles, are fabrics that have built-in functions such as sensing, data storage and communication. But as with all electronics, they require a power source. Conventional batteries are too bulky to wear, so a power source that can be combined and integrated into the garment is highly desirable.

Previous attempts to make wearable energy storage devices involved the use of nonwoven materials not usually used in clothes and expensive active materials like carbon nanotubes and nanowires.

Yury Gogotsi and colleagues at Drexel University, Philadelphia, have taken everyday fabrics like woven cotton and polyester materials and impregnated them with porous carbon powders, taking advantage of the natural porous nature of these materials. Using common techniques like screen printing, ink-jet printing and dip-coating, textile electrodes can be made on a large scale without the expense of new processes needing to be designed.

A battery can be integrated into a garment by impregnating woven cotton and polyester fabrics with porous carbon

‘Our work makes a significant advancement in this area as our electrodes can store 400-700 times the energy per area of previously reported literature while also being flexible, non-toxic and has great potential to be integrated into textiles and clothing,’ says Gogotsi.

The woven and knitted fabrics have empty space between individual fibres and between yarns, and it is into these spaces that the carbon powders are inserted, allowing ion transfer. The team were able to achieve higher mass loadings and capacitance levels on comparison with previous techniques.

‘The relatively simple approach to engender conductivity to textile substrates has broad impact,’ comments Tushar Ghosh, a specialist in textile engineering from North Carolina State University, US. ‘The work contributes to the body of knowledge necessary for energy harvesting and storage in textiles of the future.’

Although more work is needed to get a finished product, the hope is to develop this technology into a number of smart garment devices that can be used in a variety of fields such as healthcare, the army and even aerospace exploration.

Rebecca Brodie

Read the paper from Energy & Environmental Science:

Carbon coated textiles for flexible energy storage

Kristy Jost, Carlos R. Perez, John K. McDonough, Volker Presser, Min Heon, Genevieve Dion and Yury Gogotsi

Energy Environ. Sci., 2011

DOI: 10.1039/c1ee02421c