The next generation of flexible electronic devices will use transparent nanopaper, a flexible, renewable and tunable substrate that can be used in thin film resistors, organic light emitting diodes and organic photovoltaics.

Renewable, flexible paper electronics have been a tantalizing prospect for quite a while, yet they suffered from significant flaws including large surface roughness and high opacity. New techniques have been developed to extract what is known as nanofibril cellulose (NFC) from natural wood fibers. The paper that can be made from NFC has high transparency, extremely low surface roughness and good mechanical properties. This review article covers fabrication techniques for nanopaper, optical and mechanical properties of the nanopaper, and devices constructed using electronics on transparent nanopaper.

While researchers are still working to develop high throughput, low energy fabrication techniques for nanopapers, the currently developed techniques have already yielded paper with exciting properties. The optical transparency of the nanopaper can be as high as 90%, and the amount of haze can be tuned to optimize for a variety of applications. High haze is ideal for light scattering in photovoltaics and in screens for outdoor viewing, while low haze is optimal for high clarity screens for indoor viewing. Nanopaper also has extremely low surface roughness (5 nm), high mechanical strength and low thermal expansion.

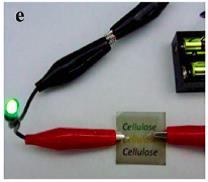

These physical and optical properties make nanopaper an ideal medium for the next generation of flexible electronics. When coated with a conductive layer such as ITO, carbon nanotubes or silver nanowires, the conductivity of the nanopaper is high enough to allow it to be used in thin film transistors and organic LEDs. Though not yet as efficient as plastic substrates, nanopaper can also be used to make organic photovoltaics with much higher efficiencies than those with paper substrates. Finally, researchers have created a resistive touch screen from nanopaper – one that outperforms PET (polyethylene terephthalate) in sunny conditions.

Want to know more? Check out the full article in EES today!

Transparent paper: fabrications, properties, and device applications

Hongli Zhu, Zhiqiang Fang, Colin Preston, Yuanyuan Li and Liangbing Hu

DOI: 10.1039/c3ee43024c