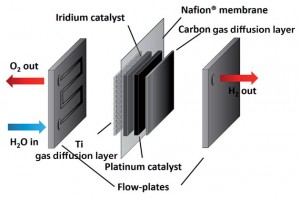

By using 3D printing researchers in the UK have cut the cost of manufacturing devices that produce hydrogen fuel by splitting water. The 3D printed plastic components developed by Lee Cronin and co-workers at the University of Glasgow, UK, allow for the construction of light weight and low-cost electrolysers that could make the currently expensive devices available to a wider audience. Hardware hackers in the scientific community are also encouraged to use the new manufacturing approach in open source developments.

Interested to find out more? For the full article visit Chemistry World.

Read the original article in Energy and Environmental Science – free to access until August 15th!

Lee Cronin, Greig Chisholm, Philip Kitson, Niall Kirkaldy and Leanne Bloor

Energy Environ. Sci., 2014, Accepted Manuscript