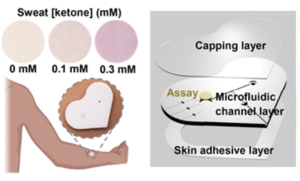

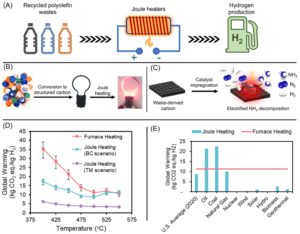

To combat climate change, we must reduce carbon footprints either through waste reduction or renewable energy. Plastic waste is a significant challenge, with millions of tons ending up in landfills and oceans each year. Thus, it is of immense importance to reduce or recycle plastic waste, or even convert it to useful materials. In a recent study, Z. Qiang et al. show how upcycled plastics, like polyethylene and polypropylene, can be converted into energy-efficient heating elements for clean hydrogen production, tackling both waste reduction and recycling issues simultaneously (Illustrated in Figure 1A). The key innovation in this study lies in transforming discarded plastic into a special kind of carbon material by a combination of techniques, including 3D printing, crosslinking, and pyrolysis (a high-heat process that breaks down materials) to turn plastics into a highly efficient heating element (Figure 1B). The plastic waste is first printed into 3D structures, then chemically treated to make it stronger. Finally, it’s heated to the point where it becomes carbon. This carbon material can then be used as both a catalyst support and a heater in ammonia decomposition for producing hydrogen without harmful emissions (Figure 1C). This simple carbon-based Joule heater heats up when electricity passes through it and is a more efficient method than traditional convection heaters, while offering quicker start-up and shutdown times. That’s a game-changer when it comes to making hydrogen production faster and more energy-efficient.

Figure 1: (A) Illustration demonstrating the upcycling of recycled mixed polyolefin waste to carbon-based Joule heaters for hydrogen production. (B) Mixed waste compounded into 3D-printing filament, and FFF-printed into structured parts turning into structured carbon and connected to a power source to demonstrate Joule heating capabilities. (C) Waste-derived carbons impregnated with Ru-based catalysts for Joule heating-enabled NH3 decomposition for hydrogen production. (D) The global warming impact of furnace heating and Joule heating for ammonia decomposition at different temperatures. (E) The global warming impact of ammonia decomposition by Joule heating (blue bars) versus conventional furnace heating (red line) for various energy sources. Reproduced from DOI: 10.1039/d4mh01755b with permission from the Royal Society of Chemistry.

So basically, the Joule heating isn’t just about generating heat—it’s about doing it in a cleaner, smarter way. Traditional methods of heating can be energy-hungry and slow but using electricity to directly heat materials through Joule heating is much more efficient. In the study, this improved heating method sped up the ammonia decomposition process, allowing for faster hydrogen production. Even better, the process also reduces carbon emissions and energy use compared to conventional methods (Figure 1D, E). That means we can make hydrogen in a cleaner, more sustainable way, helping to reduce our reliance on fossil fuels. The exciting thing about this study is a double win for the planet. On one side, it helps address the massive problem of plastic waste by turning it into something useful. On the other side, it helps create hydrogen, a clean energy source to power everything from vehicles to industrial processes, without any harmful emissions, which paves the way towards zero carbon footprint.

It will be more interesting to see if this approach could also be used in other industries beyond hydrogen production. For instance, replacing the old, carbon-intensive heating systems used in manufacturing with these waste-derived Joule heaters could save massive energy consumption and reduce enormous emissions. Therefore, this research is a big step to address the real-world problem of waste, which will be no longer a problem, but a resource. By linking energy production with material recycling, we can close the loop on waste and make industries cleaner and more efficient. However, it would be preliminary to expect its use at larger scale in various energy sectors. Challenges like ensuring consistent carbon material properties at large scale, long-term thermal stability under high temperatures, and seamless integration with existing hydrogen production systems could be challenging.

To find out more, please read:

Upcycling of mixed polyolefin wastes to 3D structured carbon Joule heaters for decarbonized hydrogen production

Anthony Griffin, Jiachun Wu, Adam Smerigan, Paul Smith, Gbadeoluwa Adedigba, Rui Shi, Yizhi Xiang and Zhe Qiang

Mater. Horiz., 2025, Advance Article

About the blogger

Dr. Shahid Zaman is postdoctoral fellow at the Hydrogen Research Institute, University of Quebec Trois-Rivières (UQTR), Canada, and a member of the Materials Horizons Community Board. He completed his Ph.D. in Material Physics and Chemistry from Huazhong University of Science and Technology in 2021. His research focuses on the development of nanomaterials for electrocatalysis, particularly in proton exchange membrane fuel cells and water electrolyzers. |