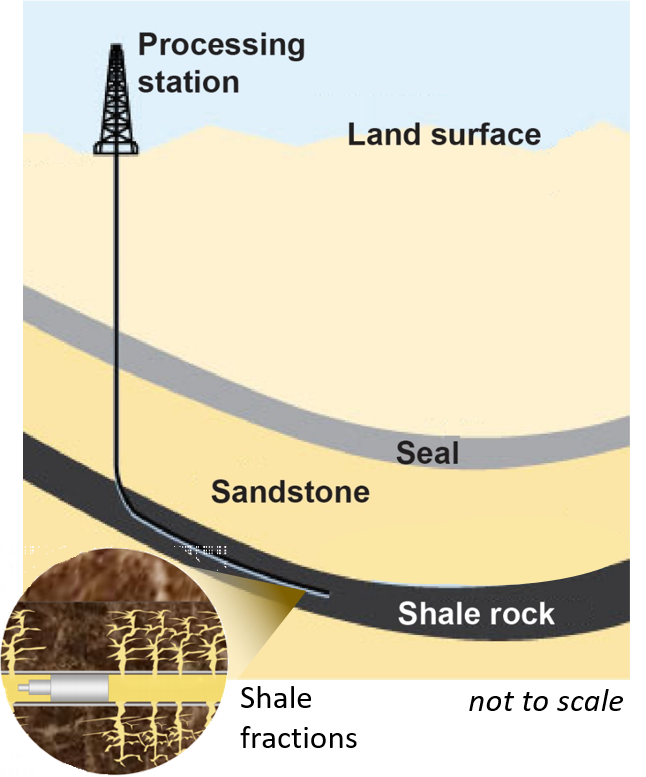

Shale is a type of fine-grained rock that contains silt, clay, mineral particles, and pores ranging from meter to nanometer scales. The high organic material content in shale rock is used in natural gas extraction, for which shale reservoirs are mechanically stimulated to create permeability in the pores. A preferred stimulation method is called hydraulic fracturing, where a pressurized fluid fractures shale stone and keeps the fractures open for gas extraction (Figure 1). Natural gas extraction from shale rock is a relatively new process compared to existing energy sources. It has attracted growing interest in America and Asia especially after the 2000s because of being an environmentally friendly alternative to other consumable energy sources. On the other hand, the gas industry currently struggles with optimizing the use of pore space and fractions for efficient extraction of the gas. In a newly opened shale rock reservoir, volatile components vaporize from meter to micrometer-scale pores first, leaving heavier components in hard-to-access nanometer-scale pores. Extraction of the remaining components is necessary for full utilization of the reservoirs but poses a hard-to-solve problem for the industry.

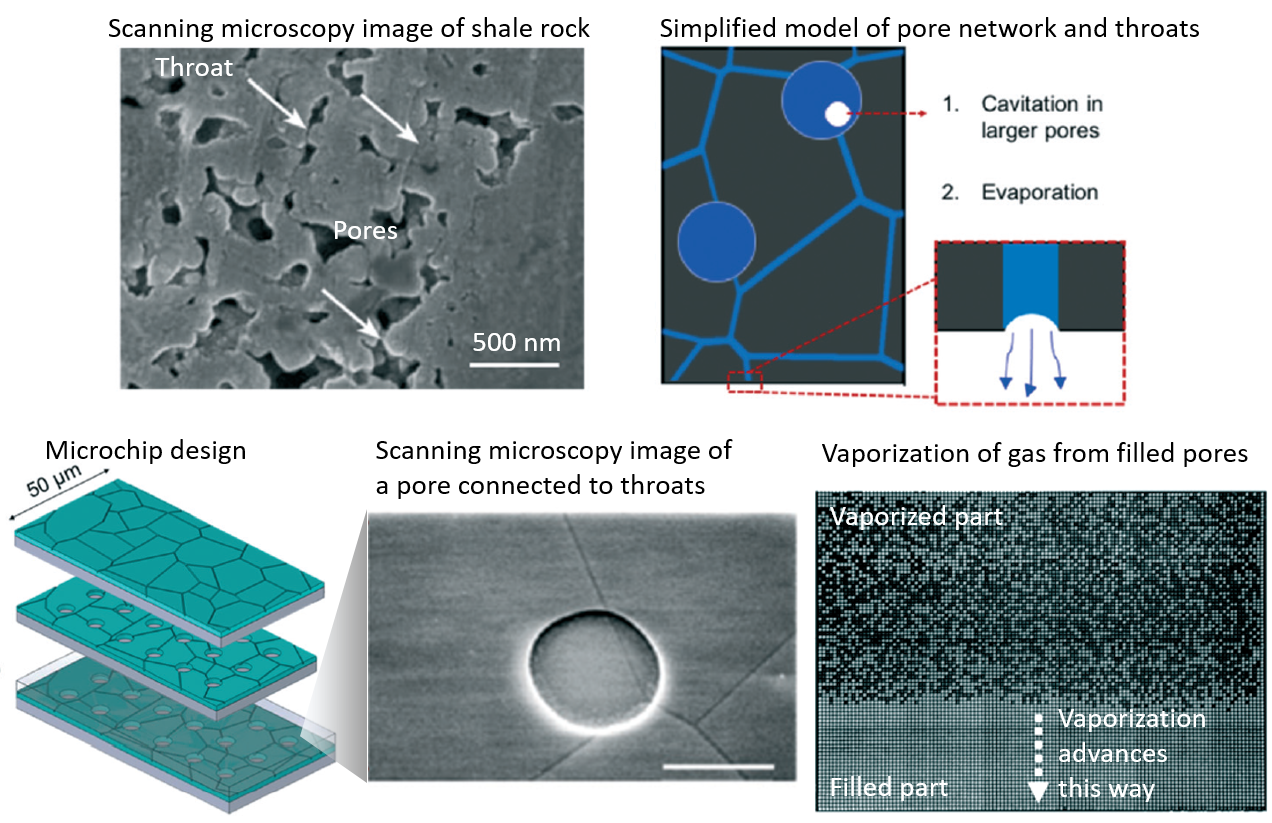

In a recent study published in Lab on Chip, David Sinton and co-authors review the current state of the technology and demonstrate a nano-scale physical model of shale with pores. The authors also study the dynamics of gas production in nanopores via imaging the system optically and developing an analytical model for gas vaporization. They first created a microchip model matching shale nanoporous matrix properties (e.g., dominant pore sizes and permeability) (Figure 2). The microchip model contained approximately 5800 pores connected via 23000 throats, where a hydrocarbon mixture was injected. In the model, the number of the small pores (≤10 nm) is designed to be greater than the number of the larger pores (∼100 nm) to store most of the accessible hydrocarbons. This pore size distribution captures the influence of nanoscale throats connecting the larger pores and is relevant to shale production. High, medium, and low superheat was applied to the filled microchip to investigate the spatiotemporal dynamics of vaporization via optical imaging. An analytical model and experimental results showed that phase change (liquid to vapor) in a pore is largely independent of phase change in neighboring pores.

This work supports the hypothesis that the rapid decline in production rates is due to a shift from the large connected features to the nanoporous matrix, as over time the smallest pores become enriched with heavier fractions. The authors reveal that vaporization rate slows down 3000 times thanks to the nanoscale throat bottlenecks at high temperatures, while the rates reduce further with vaporization of light components in large pores at low temperatures. Even the pores with 10 nm and fewer diameters can significantly influence the production from larger pores by severely gating transport. The authors found that this problem can be solved by applying very low pressures, although currently not available in the field, during the later stages of hydraulic fracturing. This finding seems to open a new avenue in the field of shale rock processing for energy.

Figure 2. Close up view of shale rock, the description of how the evaporation works, and the description of the microchip operation.

To download the full article for free* click the link below:

Arnav Jatukaran, Junjie Zhong, Ali Abedini, Atena Sherbatian, Yinuo Zhao, Zhehui Jin, Farshid Mostowfi and David Sinton

Lab Chip, 2018, Lab on a Chip Articles

DOI: 10.1039/c8lc01053f

*Article free to read until 7th May 2019

Burcu Gumuscu is a researcher in Mesoscale Chemical Systems Group at University of Twente in the Netherlands. Her research interests include the development of microfluidic devices for quantitative analysis of proteins from single-cells, next generation sequencing, compartmentalized organ-on-chip studies, and desalination of water on the microscale.