A device to deposit polymer layers on oil droplets has been made by researchers from Singapore, who say that their design is faster and

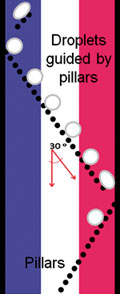

Oil droplets are guided through three liquid streams - two polymers and a washing station - by micropillars arranged in a zigzag fashion

more efficient than conventional deposition techniques and it achieves the highest number of polymer layers reported so far using microfluidics. The device could be used to encapsulate drugs for delivery or be used to create capsules for biosensing.

Dieter Trau from the National University of Singapore and colleagues have used a method that they call ‘microfluidic pinball’ to guide oil droplets through channels created by rows of micropillars, like a pinball machine. The rows are orientated in a zigzag fashion across three liquid streams – two polymers and a washing station. The angles created by the rows, as well as the flow rates in the streams, determine how long droplets stay in each channel.

The droplets are guided along the rows to travel repeatedly through the three streams. The team found that six polyelectrolyte layers could be deposited on a droplet in under three minutes – they were able to see the layers with fluorescence spectroscopy. Atomic force microscopy revealed the thickness of each layer to be approximately 2.8nm.

Read Jennifer Newton’s Chemistry World article online here or go straight to the HOT Lab on a Chip paper:

A microfluidic pinball for on-chip generation of Layer-by-Layer polyelectrolyte microcapsules

Chaitanya Kantak, Sebastian Beyer, Levent Yobas, Tushar Bansal and Dieter Trau,

Lab Chip, 2011

DOI: 10.1039/c0lc00381f