A picoliter of a droplet is approximately 1 µm. It is so small that a raindrop can contain thousands of picoliters. Despite the small quantity, precise control of picoliter size liquids spawns a growing number of applications including in point-of-care tools and drug synthesis. Such a task is not easy to achieve for conventional liquid-manipulation methods due to precision, evaporation and the ease of post-processing problems.

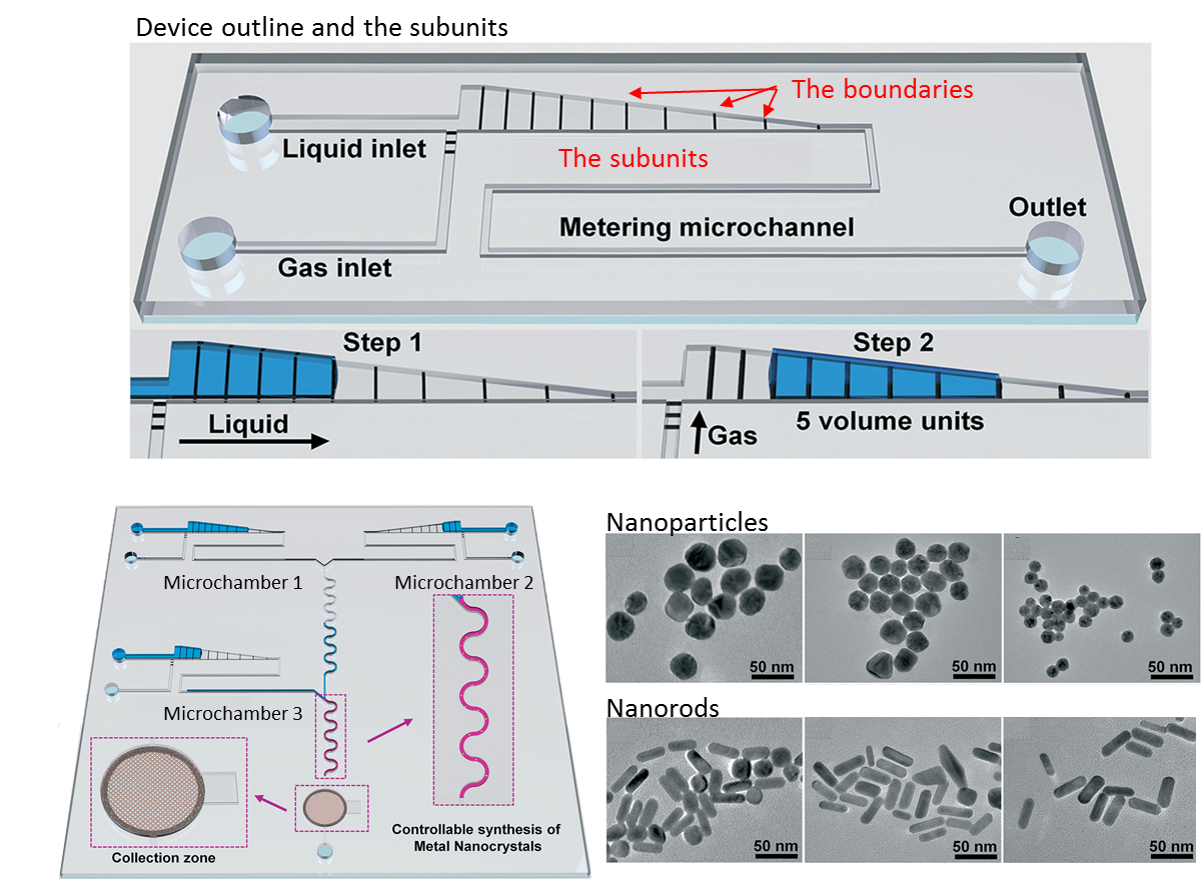

When it comes to small volume liquid handling, no other platform would be better than microfluidic devices. As such, a recent Lab Chip paper from Prof. Bai Yang’s Lab at Jilin University in China demonstrates the fabrication of a microfluidic platform to handle sub-picoliter size droplets. The authors use glass as the core material of the microchips because glass is mechanically strong and it enables higher precision in droplet manipulation (Figure 1). In the paper, pressure-controlled syringes are used to dispense down to 0,5 picoliters in a series of trapezoidal-shaped microchambers, each composed of 10 subunits. The boundaries of the subunits act as pressure barriers, preventing the liquid from flowing through the entire microchamber and allowing for fine-tuning of the volume to be handled. The authors also showed that the working range, stability, and precision of the device could be increased by adjusting the boundary properties and microchamber dimensions (e.g., height). However, the magnitude of the minimum volume will still be bound to two main factors. (1) The resolution of the fabrication technology determines the microchannel and boundary dimensions. (2) Laplace pressure difference between the channel and the boundaries determines the accuracy of the device. The smaller channels yield decreased accuracy due to higher pressure differences between the boundary-microchannel interfaces. Relying on these design criteria, the authors fabricated up to three interconnected picoliter-volume injection units. Combined units work together to synthesize gold nanoparticles and nanorods with a wide size range. The authors believe that the platform can be further used in several different applications including lab-on-chip platforms, analytical chemistry for medicine approaches, quantitative cell cultures, and even drug injection into single cells.

To download the full article for free* click the link below:

Nianzuo Yu, Yongshun Liu, Shuli Wang, Xiaoduo Tang, Peng Ge, Jingjie Nan, Junhu Zhang, and Bai Yang, Lab Chip, 2019, Lab on a Chip Hot Articles

DOI: 10.1039/C9LC00730J

Burcu Gumuscu is a researcher in Mesoscale Chemical Systems Group at the University of Twente in the Netherlands. Her research interests include the development of microfluidic devices for quantitative analysis of proteins from single-cells, next-generation sequencing, compartmentalized organ-on-chip studies, and desalination of water on the microscale.