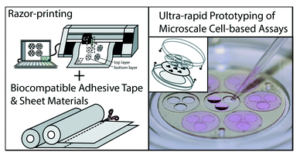

Sticker-like devices enable quick, rapid prototyping for cell culture experiments

Xurography, or razor-printing, is a low-cost and accessible method for fabricating microfluidic devices. By using a computer controlled razor cutter, sheets of material can be cut precisely to a design. Using adhesive materials, the cut patterns can be used like stickers, and microfluidic devices can then be made by stacking and layering the stickers to create three-dimensional structures. While razor-cut devices might not have the same resolution as soft lithography (150 μm vs. 10-30 μm), their ease of fabrication and rapid turnaround time makes the method very user-friendly and great for rapid prototyping. It is precisely for their ease of use that Jay Warrick (U. Wisconsin) and Maribella Domenech (U. Puerto Rico at Mayagüez) wanted to work with razor-cut microfluidics.

Having access to a very easy fabrication method became a necessity for Domenech. After an electrical fire destroyed her lab and soft lithography equipment in 2016, Domenech was looking for an easy way continue her research while waiting for renovations to be completed. Since she works primarily with undergraduate research students, she needed a fabrication method with a gentle learning curve. “Lithography methods are too difficult to be mastered within a couple of weeks, but razor-cut devices are easy for anyone to fabricate and use,” says Domenech.

As easy and accessible as any method may be, it won’t gain widespread adoption by a community unless it’s trusted. For biologists, this means trusting that the material is biocompatible and won’t interfere with their experiments. In their recent report, Domenech and Warrick address this challenge and do a service to the community by thoroughly characterizing ARcare 90106, a double-sided adhesive tape for xurography. The tape was compared to polystyrene and PDMS devices, the bread and butter materials of cell biology and microfluidics, respectively. The tape showed good performance across a variety of metrics of cell growth and with a range of cell types. Further, it compared favorably to PDMS in terms of absorption of lipophilic molecules, which means it is less likely to interfere with co-culture experiments where the diffusion of extracellular molecules (e.g., hormones, cytokines, growth factors etc.) is very important.

Easy-made tape-based biocompatible devices open up new opportunities for cell biology. “It’s quite enabling to be able to adhere these devices to so many different types of surfaces,” says Warrick. And because the tape is flexible, it can stick on curved surfaces as well as flat. It also opens up opportunities to integrate new materials with microfluidic devices. Warrick says he’s “often looked at different materials and wished there was an easy way to integrate them. Tape solves this.” In terms of new materials, the team demonstrated the integration of sheets of electrospun collagen within razor-cut microfluidic devices, and co-lead author Yasmín Álvarez-García is currently investigating what other materials could be incorporated. She hopes to expand the current work to include more cell types, perform cell migration studies, and expand the usability of the technique. This will further increase the trustworthiness of the tape’s biocompatibility and lower the barriers for more biologist to get into microfluidics.

To read the full paper for free*, click the link below:

Razor-printed sticker microdevices for cell-based applications

DOI: 10.1039/c7lc00724h (Paper), Lab on a Chip, 2018, 18, 451

__________________

Darius Rackus (Right) is a postdoctoral researcher at the University of Toronto working in the Wheeler Lab. His research interests are in combining sensors with digital microfluidics for healthcare applications.

*free access until 28th February 2018