The magic of magnetism can be shown through a simple classroom demonstration of bringing two magnetic pieces together and then trying to pull them apart. The attraction between the opposite poles of the magnets becomes very apparent as you struggle to tear them apart. This simple concept can be applied to lab-on-a-chip devices to eliminate the need for off-device hardware with power requirements, and therefore, enable the use of lab-on-a-chip technology in low-resource settings.

The majority of existing lab-on-a-chip systems use manual pipettes, syringe pumps, or pressure pump systems to manipulate the fluid flow. The dependence on off-chip hardware, however, makes the integration of these systems into low-cost environments rather challenging. Researchers in both, academia and industry think that this challenge can be addressed by “manually operated self-contained microfluidic devices”, which has gained significant attention over the past couple of years. In line with this objective, magnetically-adhesive based valves have for the first time shown to control fluid flow in a microfluidic device in a recent collaboration work by Sandia National Labs and Qorvo Inc. Here, the “magnetic-adhesive based valve” simply consists of a disk magnet seated on a thin ring of adhesive material.

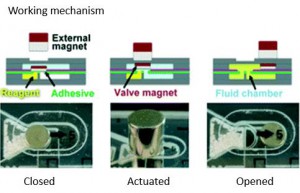

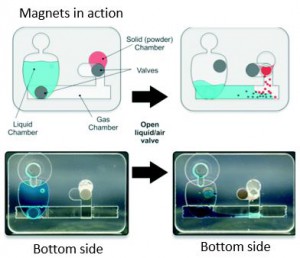

In this study, a microfluidic device is designed to perform bioassays and contains a port connecting two chambers in different planes. The port is closed by an internal magnet located on a pressure-sensitive adhesive tape, and is opened by the help of an external magnet which displaces the internal magnet (figure 1). When the port is open, the reagents can flow in the microchannels, as shown in figure 2. The adhesive tape prevents any leakage within the microchip, while the magnet serves as an actuatable gate for reagents. The microfluidic device, therefore, allows for storage and on-demand transport of different types of reagents (both liquid, solid, and gas) to perform bioassays.

Magnetic-adhesive based valves are fabricated at the millimeter-scale, however, it is possible to manufacture micron-sized valves depending on the resolution of the laser ablation system used to cut the valve layout. Design considerations and characterization of magnetic-adhesive based valves are further addressed in the paper. Apart from this, the self-contained device is made of low-cost materials (such as PMMA and magnetic alloys), resulting in a fabrication cost as low as 0.2 dollars per chip. As portable and low-cost devices start to draw increasing attention in lab-on-a-chip technology, this work might be an important milestone for next generation micro total analysis systems.

Figure 2. Controlled transport and reaction of the stored components in a simple, power- and instrument-free manner in a three chambered microfluidic device.

This is a recently published Hot article and you can download it for free* by clicking the link below:

Magnetic-adhesive based valves for microfluidic devices used in low-resource settings

Jason C. Harper, Jenna M. Andrews, Candice Ben, Andrew C. Hunt, Jaclyn K. Murton, Bryan D. Carson, George D. Bachand, Julie A. Lovchik, William D. Arndt, Melissa R. Finley and Thayne L. Edwards

Lab Chip, 2016, Recent HOT Articles

DOI: 10.1039/C6LC00858E

About the Webwriter

Burcu Gumuscu is a postdoctoral fellow in BIOS Lab on a Chip Group at University of Twente in The Netherlands.