If the Lab on a Chip HOT articles are anything to go by, using microalgae as a feedstock for biofuel is definitely a flourishing research area. Microalgae is a particularly attractive feedstock as it grows rapidly, has a large oil content, and can be grown pretty much anywhere.

David Sinton and co-workers at the University of Toronto have previously published in Lab on a Chip on this topic and have now reported their work on optimising the conditions for converting microalgae ‘biomass’ into crude biofuel (‘biocrude’). The process by which this is achieved is known as hydrothermal liquefaction. High temperatures and pressures are employed to break down the organic compounds from the biomass into the oils that make up biocrude.

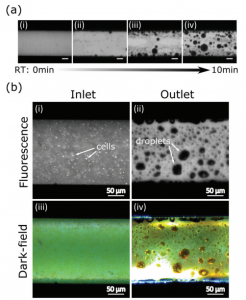

a) Fluorescence images at increasing reaction time; b) Fluorescence and dark-field imaging of fluids at inlet and outlet.

The Sinton lab have developed a microfluidic chip in order to accurately control the reaction conditions of this process and also to study the effect of changing conditions on the biofuel that is formed. The continuous flow and small volume of the chip allow very fast heating of the algal slurry so reaction times can be accurately studied – in fact the heating rate achieved is the fastest reported to date. The slurry was analysed in situ by fluorescence imaging and changes to the fluorescence signature were monitored. Over the course of the reaction, the fluorescence signal due to chlorophyll disappeared and a new peak developed, indicating the formation of the aromatic compounds that are a characteristic component of crude oil and plant based oils.

Further analysis of the samples collected from the chip outlet found that the energy content (measured by the elemental composition) of the biocrude reached saturation after short reaction times – much before the fluorescence signal stopped changing. In addition to this, non-fluorescent droplets could be seen inside the reaction chamber, as shown in the diagram on the left, which were presumed to comprise of aliphatic oils. These findings indicate that analysis of the elemental composition alone is insufficient to measure chemical conversion to biocrude and methods such as fluorescence imaging should also be employed.

This work is the first example of using a microfluidic platform in hydrothermal liquefaction research and just goes to highlight the versatility of lab-on-a-chip systems.

To download the full article for free* click the link below:

Biomass-to-biocrude on a chip via hydrothermal liquefaction of algae

Xiang Cheng, Matthew D. Ooms and David Sinton

Lab Chip, 2016, 16, 256-260

DOI: 10.1039/C5LC01369K

—————-

About the webwriter

Claire Weston is a PhD student in the Fuchter Group, at Imperial College London. Her work is focused on developing novel photoswitches and photoswitchable inhibitors.

—————-

*Access is free through a registered RSC account until 29/02/2016.