Electrochemical sensors are widely used as analytical tools. They are disposable, cheap to make, and small – making them ideal for many applications.

The current method for commercial electrochemical sensors uses screen printing onto plastic or ceramic surfaces to generate the circuit elements, which requires specialised fabrication equipment. This screen printing method also leads to wastage of electrode inks and reagents. One way of avoiding these issues is using paper microfluidics – Professor George Whitesides is a well-known name in this field.

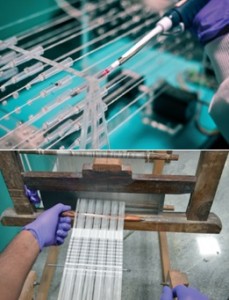

Dendukuri and coworkers, from Achira Labs, Bangalore, have come at this problem from a different angle. They have developed an alternative approach using textile weaving. Instead of screen printing, they coat their yarn with the required reagents in a way that results in no wastage, as shown in the photo. They use silk as their material which is biodegradable, unlike the plastics usually used. It is also easily processed – initially silk is hydrophobic but it can be made hydrophobic by degumming. This can be achieved by simply boiling the yarn.

Dendukuri and coworkers, from Achira Labs, Bangalore, have come at this problem from a different angle. They have developed an alternative approach using textile weaving. Instead of screen printing, they coat their yarn with the required reagents in a way that results in no wastage, as shown in the photo. They use silk as their material which is biodegradable, unlike the plastics usually used. It is also easily processed – initially silk is hydrophobic but it can be made hydrophobic by degumming. This can be achieved by simply boiling the yarn.

To make the sensors, electrode yarns are prepared by coating in conductive inks and reagents, and then woven into the fabric. Large numbers of sensors can be woven as patches on the fabric, which are then stuck onto an adhesive backing and laminated, leaving a window for application of the sample and for contact with a reader.To demonstrate this effectiveness of this new method, the authors developed glucose and haemoglobin sensors. The glucose sensors were found to have a clinically acceptable performance, according to FDA criteria, while the haemoglobin sensors were able to detect physiologically relevant concentrations. Multiplexed sensors capable of detecting more than one analyte were easily prepared by adding an additional electrode.

One of the most pleasing aspects of this new method, is its potential in the developing world, where weaving is still widely used. In addition, the cost of manufacture was calculated as less than 20 USD per 1000 sensors and this could even lower on scale up.

To download the full article for free* click the link below:

Woven electrochemical fabric-based test sensors (WEFTS): a new class of multiplexed electrochemical sensors

Tripurari Choudhary, G. P. Rajamanickam and Dhananjaya Dendukuri

DOI: 10.1039/C5LC00041F

*Access is free until 30.04.2015 through a registered RSC Personal Publishing Account