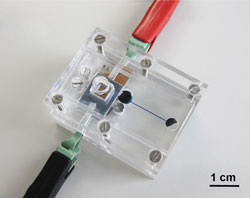

Hydrocyclones are widely used in industries such as petrochemicals and mining for the separation of particulates from fluids at the macro- and mesoscale. This is the first report of microscale hydrocyclone, tested on polystyrene microbeads suspended in PBS, providing continuous separation with exceptional flow rates and without clogging. Microfluidic applications potentially include chemical analysis, materials research, point-of-care and blood sample preparation.

Hydrocyclones are widely used in industries such as petrochemicals and mining for the separation of particulates from fluids at the macro- and mesoscale. This is the first report of microscale hydrocyclone, tested on polystyrene microbeads suspended in PBS, providing continuous separation with exceptional flow rates and without clogging. Microfluidic applications potentially include chemical analysis, materials research, point-of-care and blood sample preparation.

Microfluidic device based on a micro-hydrocyclone for particle–liquid separation

P. Bhardwaj, P. Bagdi and A. K. Sen

DOI: 10.1039/C1LC20606K

Cyclic olefin copolymer has been used to create a whole microfluidic device through microinjection moulding with the aim of bridging the gap between lab techniques and mass production of lab on a chip devices. The team that successfully developed the platform have also come up with a dimensionless number μf to provide an insight into the physics of microinjection moulding.

Cyclic olefin copolymer has been used to create a whole microfluidic device through microinjection moulding with the aim of bridging the gap between lab techniques and mass production of lab on a chip devices. The team that successfully developed the platform have also come up with a dimensionless number μf to provide an insight into the physics of microinjection moulding.

Sustainable fabrication of micro-structured lab-on-a-chip

Hwa Jin Oh, Jae Hong Park, Seok Jae Lee, Byeong Il Kim, Young Seok Song and Jae Ryoun Youn

DOI: 10.1039/C1LC20441F