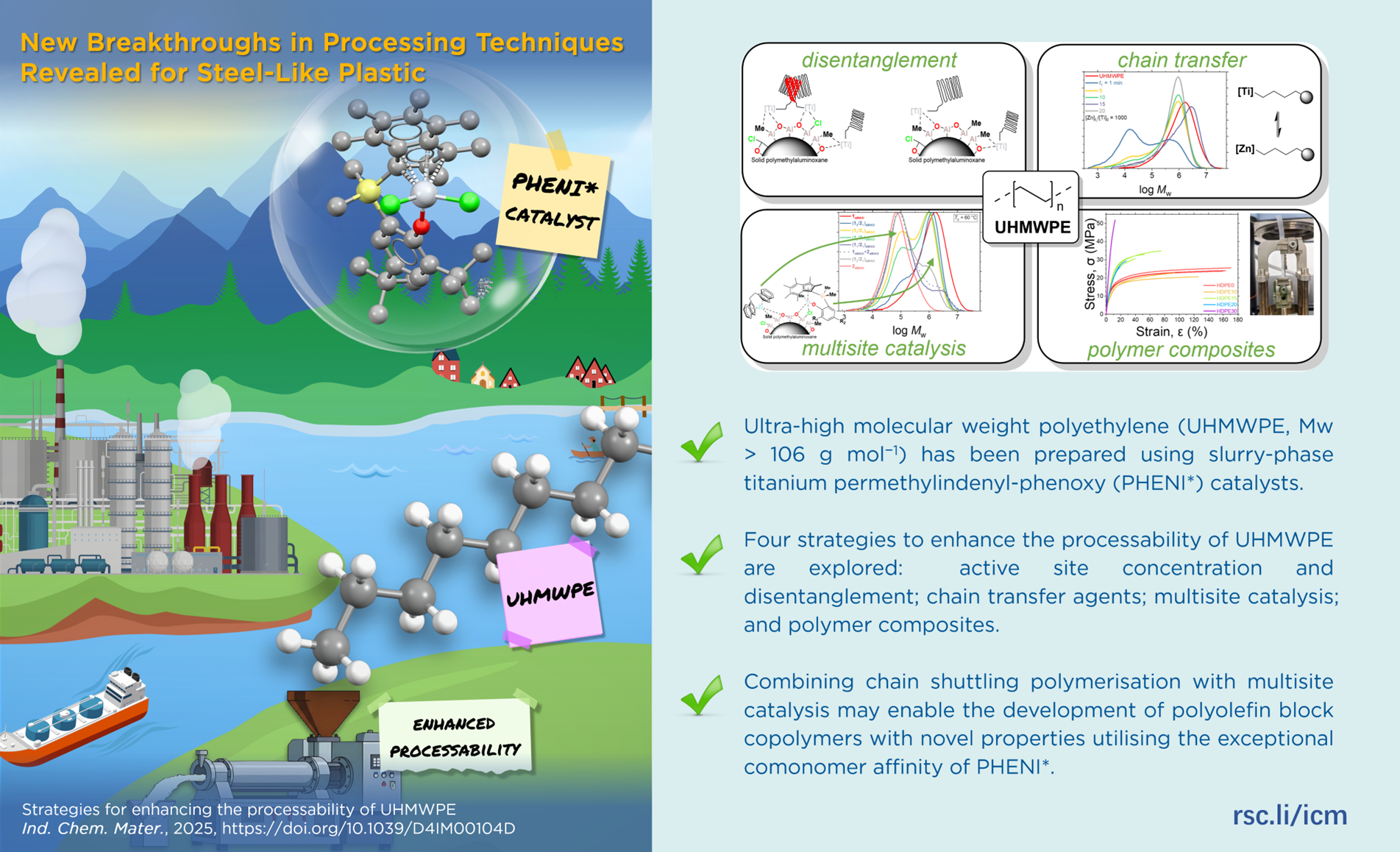

Strategies for enhancing the processability of UHMWPE

Clement G. Collins Rice, Alexander Evans, Zoë R. Turner, Jirut Wattoom and Dermot O’Hare*, University of Oxford

Ind. Chem. Mater., 2025, https://doi.org/10.1039/D4IM00104D

A strong and impact-resistant plastic that is comparable to steel could be on its way to more efficient processing thanks to new strategies introduced and tested by researchers based in the University of Oxford. They published their results in the journal Industrial Chemistry & Materials.

The team proposed and tested four approaches to improve the melt processibility — the process of melting a liquid material and reforming it into a solid shape or structure — of the material known as ultra-high molecular weight polyethylene, or UHMWPE. Melt processibility can become complicated when the material has high melt viscosity, meaning the liquid is thick and resists flow, according to corresponding author Dermot O’Hare, professor of chemistry at the University of Oxford.

“UHMWPE, defined by a molecular weight in the millions of Daltons that indicates the molecule’s large size and complex nature, is a specialty grade of polyethylene considered an important engineering plastic due to its desirable properties,” O’Hare said, noting applications exist for UHMWPE in the biomedical, maritime, aerospace and ballistics sectors. “However, due the long chains comprising the molecule creating entanglements, UHMWPE can be difficult to process. We investigated four strategies to improve UHMWPE melt processability, which is the chief limiting factor to applications of this high-performance polymer.”

The team first used active site engineering, which can accelerate and enhance material reactions, and found that it could substantially disentangle the large, complex molecule. By again targeting the chains comprising the material, the researchers next employed chain transfer agents, or molecular modifiers, to change the polyethylene’s weight and distribution. They also found that introducing small molecules into the UHMWPE improved the material’s processability without sacrificing the desired mechanical properties. Finally, the researchers determined that blending UHMWPE with high-density polyethylene helped improve processability.

“These approaches and combinations thereof are considered crucial to expanding the applicability of UHMWPE,” O’Hare said.

Next, the researchers said they plan to further investigate how combining various processing approaches may enable development of materials with novel properties.

This article is featured on EurekAlert!

Author Insights:

Dermot O’Hare is a Professor of Organometallic and Materials Chemistry in the Department of Chemistry at the University of Oxford. In addition, he is currently the Director of the SCG–Oxford Centre of Excellence for Chemistry and Associate Head for Business & Innovation in the Mathematics, Physical and Life Sciences Division. He leads a multidisciplinary research team that works across broad areas of catalysis and nanomaterials. His research is specifically targeted at finding solutions to global issues relating to energy, zero carbon and the circular economy. He has been awarded numerous awards and prizes for his creative and ground-breaking work in Inorganic Chemistry, including the Royal Society Chemistry Ludwig Mond Prize, the Royal Society Chemistry Tilden Medal and Royal Society of Chemistry Academia–Industry Prize.

Dermot O’Hare is a Professor of Organometallic and Materials Chemistry in the Department of Chemistry at the University of Oxford. In addition, he is currently the Director of the SCG–Oxford Centre of Excellence for Chemistry and Associate Head for Business & Innovation in the Mathematics, Physical and Life Sciences Division. He leads a multidisciplinary research team that works across broad areas of catalysis and nanomaterials. His research is specifically targeted at finding solutions to global issues relating to energy, zero carbon and the circular economy. He has been awarded numerous awards and prizes for his creative and ground-breaking work in Inorganic Chemistry, including the Royal Society Chemistry Ludwig Mond Prize, the Royal Society Chemistry Tilden Medal and Royal Society of Chemistry Academia–Industry Prize.