Daniel Alcaide Martín, Jean Cacheux, Sergio Dávila & Isabel Rodríguez

Madrid Institute for Advanced Studies in Nanoscience (IMDEA Nanoscience), Ciudad Universitaria de Cantoblanco, C/Faraday 9, Madrid 28049, Spain

1- Why is this useful?

Microfluidic devices need to be connected to fluidic pumps for regulation of the flow during the device operation1. Connecting and disconnecting devices is a tedious and time-consuming operation that often causes air bubbles which are detrimental for the fluidic experiment and a real nuisance for the time it takes to eliminate them.

Furthermore, in microfluidic experiments dealing with biomolecules or cell cultures, volumes are of concern as these materials are typically limited and/or costly. Hence, it will be very useful if the reagent filling or replacement process and the connecting and disconnecting operations to microchips are minimized to avoid both bubbles and reagents waste. Reducing the reservoir volume to the volumes needed for the experiment minimizing dead volumes will also allow saving expensive reagents.

With this aim, we have designed a fixture to make practical fluidic connections to a microchip from a pressure controller for fluidic control and device operations. It allows for easy opening and closing operations and for easy re-filling or replacement of the reagents into the microchannels without moving any tubing connection.

Here, we present a dual connector cum reservoir fixture as a practical and effective means to making fluidic connections onto polydimethylsiloxane (PDMS) microfluidic based chips. The fixture is completely built by stereolithography (SLA) 3D printing and includes two components: a piece including a reservoir with an O-ring slit and a cone shaped outlet as chip connector and, another piece that closes the reservoir and has a cone shaped inlet or air pressure connector.

This Chips and Tips builds on a previous approach,2 dealing with microchip fluidic fixtures using magnets. However, in this case, the reservoirs and release connection are moved off the chip which would be more practical to work with the chip on the microscope stage for real time observations. Moreover, it is adaptable for any chip design and particularly for microchips made in soft PDMS.

2- What do I need?

- 3D design software.

- SLA 3D printer.

- Cubic magnets.

- O-rings.

3 – What do I do?

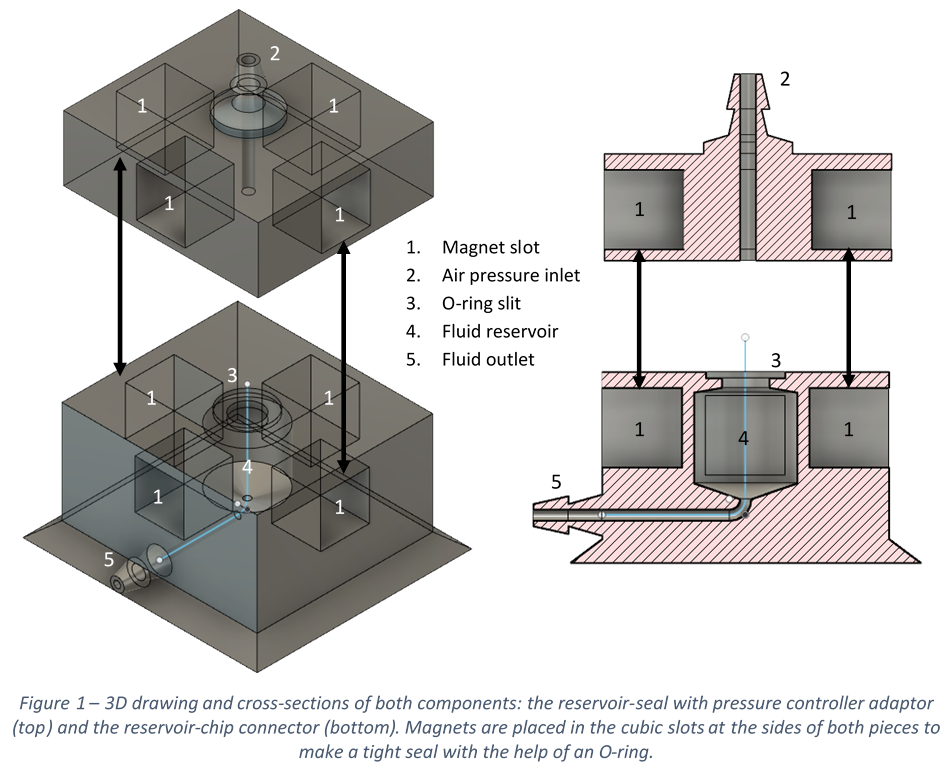

We first digitally design the parts of the dual connector: the reservoir-chip connector and the reservoir-seal air pressure adaptor. See the drawing in Figure 1. The corresponding F3D files can be here downloaded.

In our design, the reservoir sits aside from the PDMS chip and it is connected to it through a standard tube fitted on to the connecting outlet. The reservoir-seal encloses the reservoir. Four permanent magnets are inserted in each of the two components to produce a magnetic compressive force onto the O-ring and a tight seal to allow for applying a controlled pressure to cause the reagent to flow at the desired rate into the microfluidic chip.

Once the components are printed, the magnets are inserted into the lateral slots. Then, the plastic tubes are connected to the chip inlets and outlets and to the reservoir chip connector. The reservoir is filled with the correct volume of reagent (in this design is 0.2 ml) and the reservoir- seal piece is placed on top. Finally, through the air pressure inlet, tubing is connected to a pressure controller. When air pressure is applied, the reagent flows through the chip. The closing system formed by the O-ring seal and magnet force is able to handle at least 1 bar working pressure without any leakage.

Figure 2 – Fluidic system set-up showing .two dual connector-reservoir fixtures connected to a microchip and to a pressure controller.

Acknowledgements

This work was performed within the framework of the EVONANO project funded by the European Union’s Horizon 2020 FET Open programme under grant agreement No. 800983.

References

- Interfacing of microfluidic devices – Chips and Tips. https://blogs.rsc.org/chipsandtips/2009/02/27/interfacing-of-microfluidic-devices/.

- Reusable magnetic connector for easy microchip interconnects – Chips and Tips. https://blogs.rsc.org/chipsandtips/2011/06/27/reusable-magnetic-connector-for-easy-microchip-interconnects/.