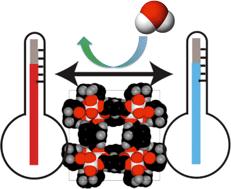

The use of fossil fuel-powered vapour compressors for the allocation of hot and cold air makes a significant contribution to global warming. A greener alternative involves reversible adsorption and desorption of a working fluid (often water) in adsorption heat pumps (AHPs) or adsorption chillers (ADCs), concepts originally devised by Michael Faraday in 1848.

The limiting factor when using MOF-based AHPs and ADCs is the rate of heat transfer. In this light, Al-based MOFs provide an attractive target as Al can not only provide a heat-conducting surface, but is also naturally abundant and of low toxicity.

MOFs for heat transfer

In their recent paper in CrystEngComm, de Lange, Gascon and co-workers evaluate a series Al-based MOFs for use in AHPs and ADCs. Of all the materials they tested, the most favourable characteristics were shown by the compound designated CAU-10-H, a material comprised of [Al–OH]2+ chains linked together by isophthalic acid, (CAU is Christian-Albrechts-Universität, where the compounds were first developed).

In the presence of hydrochloric acid, CAU-10-H can be grown directly on to γ-alumina beads or metallic aluminium. These systems show good water adsorption and stability. Up to 38kJ of heat can be withdrawn in the evaporator of an AHP/ADC per square metre of Al-coated surface, suggesting further study and development of Al-MOFs is worthwhile.

For more details, read the full paper:

Crystals for sustainability – structuring Al-based MOFs for the allocation of heat and cold

M. F. de Lange, C. P. Ottevanger, M. Wiegman, T. J. H. Vlugt, J. Gascon and F. Kapteijn

CrystEngComm, 2014, DOI: 10.1039/C4CE01073F

Gwenda Kyd has a PhD in metallocarborane chemistry from the University of Edinburgh. Other research work includes the spectroscopic study of the structure of glasses and organometallic electron-transfer reactions and the preparation of new inorganic phosphors