Posted on behalf of Gwenda Kyd, web writer for CrystEngComm

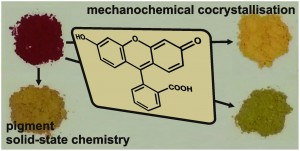

Pigments are solid colourants used in the production of materials such as paints, inks and plastics. For a given pigment, the colour is affected by particle size and morphology, among other things. Formation of a multi-componet system (co-crystal) may also affect the colour and, additionally, may alter properties like heat stability. However, pigments tend to be insoluble in common solvents, rendering production of co-crystals by conventional, solution-based, methods difficult.

A new paper shows how mechanochemical co-crystallisation (ie grinding the components in a small quantity of solvent) can produce co-crystals of the pigment fluorescein (see diagram below) quickly and in quantitative yields. Co-crystals with three different co-formers were produced each with a different colour. Attempts to produce co-crystals using solvent-based methods were also successful, but produced different co-crystals and less efficiently. Authors discuss the broad implications of the results for the pigment and dye industries, suggesting mechanochemical co-crystallisation as an efficient route to colour- and property-tunable pigments.

More information can be found in the full paper at:

Advantages of mechanochemical cocrystallisation in the solid-state chemistry of pigments: colour-tuned fluorescein cocrystals

Dejan-Krešimir Bučar, Stefan Filip, Mihails Arhangelskis, Gareth O. Lloyd and William Jones

CrystEngComm, 2013, Advance Article

DOI: 10.1039/C3CE41013G, Communication

Gwenda Kyd has a PhD in metallocarborane chemistry from the University of Edinburgh. Other research work includes the spectroscopic study of the structure of glasses and organometallic electron-transfer reactions and the preparation of new inorganic phosphors. Currently she works as a scientific database editor.

Gwenda Kyd has a PhD in metallocarborane chemistry from the University of Edinburgh. Other research work includes the spectroscopic study of the structure of glasses and organometallic electron-transfer reactions and the preparation of new inorganic phosphors. Currently she works as a scientific database editor.