Meet some of our Advisory Board members who work in nanomaterials’ interfaces

We recently introduced our inaugural Advisory Board for RSC Applied Interfaces. Each month, we will be shining a spotlight on some of our new Advisory Board members and highlighting their current research interests.

This week we are delighted to introduce Giridhar U. Kulkarni, Xing Yi Ling, Xiaogang Liu and Shu-Hong Yu as members of our inaugural Advisory Board.

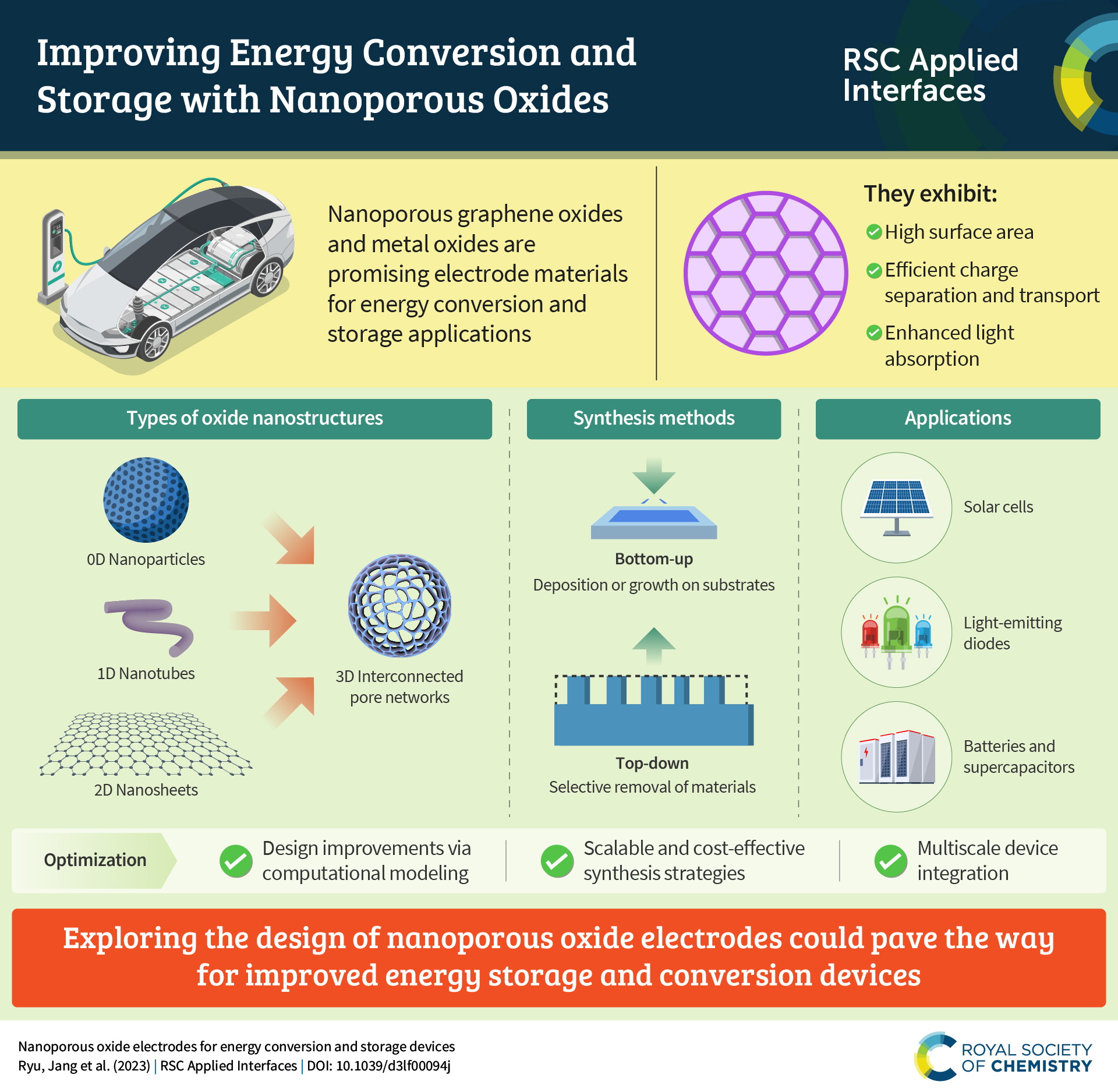

Giridhar U. Kulkarni holds a Ph.D. (1992) in Chemistry from Indian Institute of Science, Bangalore, India. After his postdoctoral studies at Cardiff University, UK (1993-95), he joined Jawaharlal Nehru Centre for Advanced Scientific Research, Bangalore. After serving as Director of Centre for Nano and Soft Matter Science, Bangalore (2015-2020), he joined JNCASR as its President. He is a Fellow of major science and engineering academies in India. His research interests include synthesis of nanomaterials of different dimensionalities and fabrication of devices. Currently, his focus is neuromorphic devices for in-memory computing and mimicking animal behaviour. He has published more than 330 papers and holds 26 patents.

“I am proud to be associated with RSC Applied Interfaces” – Giridhar U. Kulkarni

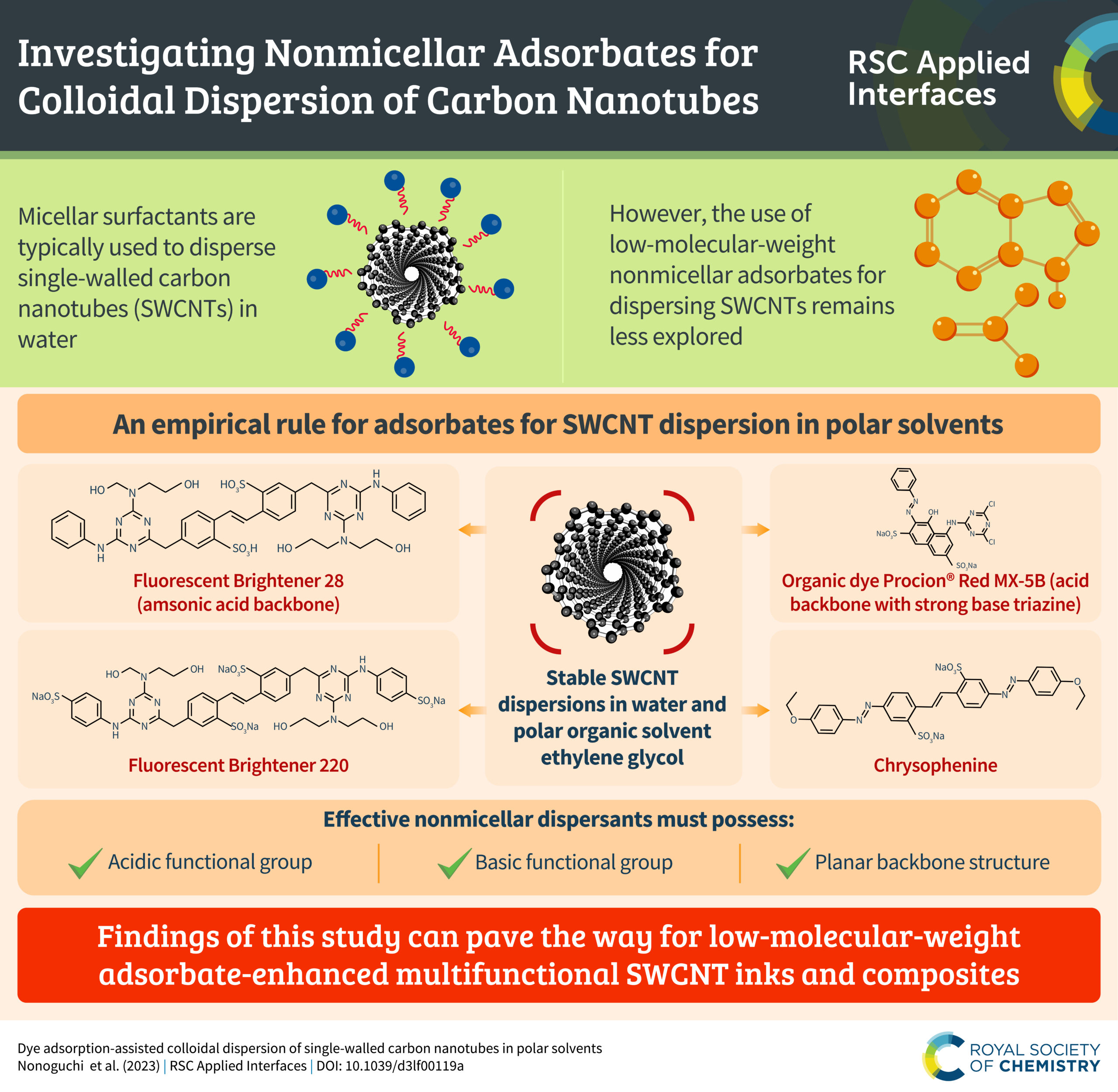

Xing Yi Ling is a Professor at Nanyang Technological University, Singapore. She was the recipient of the Lectureship Awardee at the Chemical Society Japan Annual Meeting (2016), L’ORÉAL Singapore for Women in Science National Fellowship (2015), the Asian and Oceanian Photochemistry Association prize for Young Scientist (2014), Singapore National Research Foundation Fellowship (2012), Rubicon Fellowship by the Netherlands Organization for Scientific Research (2009), and IUPAC Young Chemist award (2009). Her research group focuses on nanoparticle synthesis, surface chemistry, self-assembly, nanopatterning, nanofabrication, materials and device characterization. In particular, her group uses molecule-specific surface-enhanced Raman spectroscopy (SERS) for fundamental studies and applications in catalysis, sensing, and diagnosis.

Xiaogang Liu earned his BE degree in Chemical Engineering from Beijing Technology and Business University, China. He received his MS degree in Chemistry from East Carolina University and completed his PhD at Northwestern University. He then worked as a postdoctoral fellow at MIT for two years before joining the faculty of the National University of Singapore. He holds a joint appointment with the Institute of Materials Research and Engineering. His research interests include luminescent materials synthesis, supramolecular chemistry, transition metal-based catalysis, and surface science for sensing, optoelectronic and biomedical applications.

Shu-Hong Yu is a Professor of Chemistry at the University of Science and Technology of China. Prof. Yu’s research interests include bio-inspired synthesis of nanoscale building blocks, self-assembly and macroscopic assemblies, nanocomposites, and their functions and applications. He has authored and co-authored more than 430 refereed journal publications, 17 invited book chapters, and 26 patents. His recent awards include the 2nd Prize of National Natural Science Award awarded by Chinese Government (2010, 2016), and the Roy-Somiya Medal of the International Solvothermal and Hydrothermal Association (ISHA) (2010).

Please join us in welcoming our new Advisory Board members to the journal community!

RSC Applied Interfaces is a dedicated, interdisciplinary reference journal for cutting-edge research on the applications of surfaces and interfaces. In addition to the applied focus, work considered for publication in RSC Applied Interfaces is expected to be highly original and of top quality. The journal seeks to report major scientific advances beyond the state of the art, at the cutting edge of this interdisciplinary field.

RSC Applied Interfaces is a dedicated, interdisciplinary reference journal for cutting-edge research on the applications of surfaces and interfaces. In addition to the applied focus, work considered for publication in RSC Applied Interfaces is expected to be highly original and of top quality. The journal seeks to report major scientific advances beyond the state of the art, at the cutting edge of this interdisciplinary field.