Industrial Chemistry & Materials (ICM) warmly congratulates Professor Susumu Kitagawa, member of the ICM Advisory Board, on being awarded the Nobel Prize in Chemistry 2025.

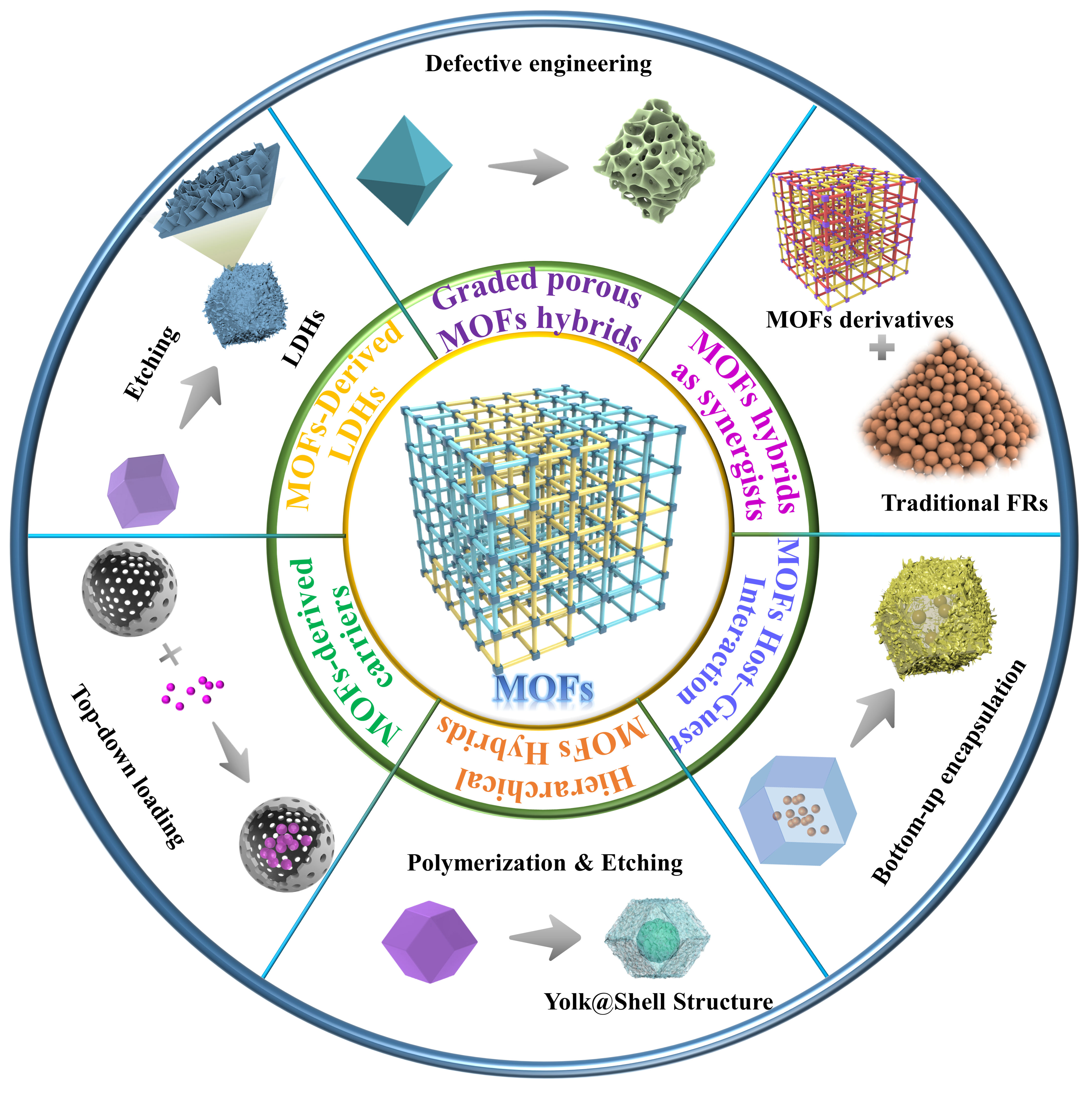

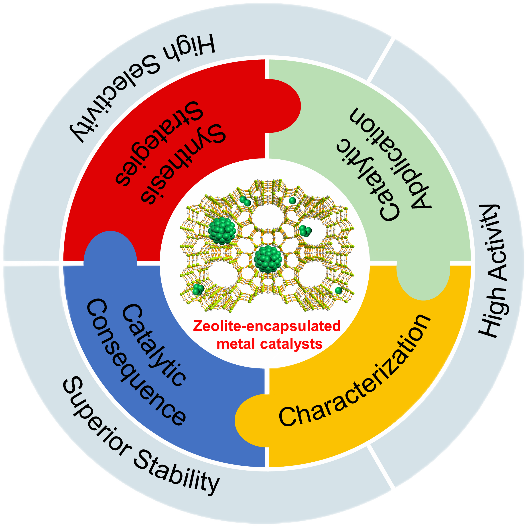

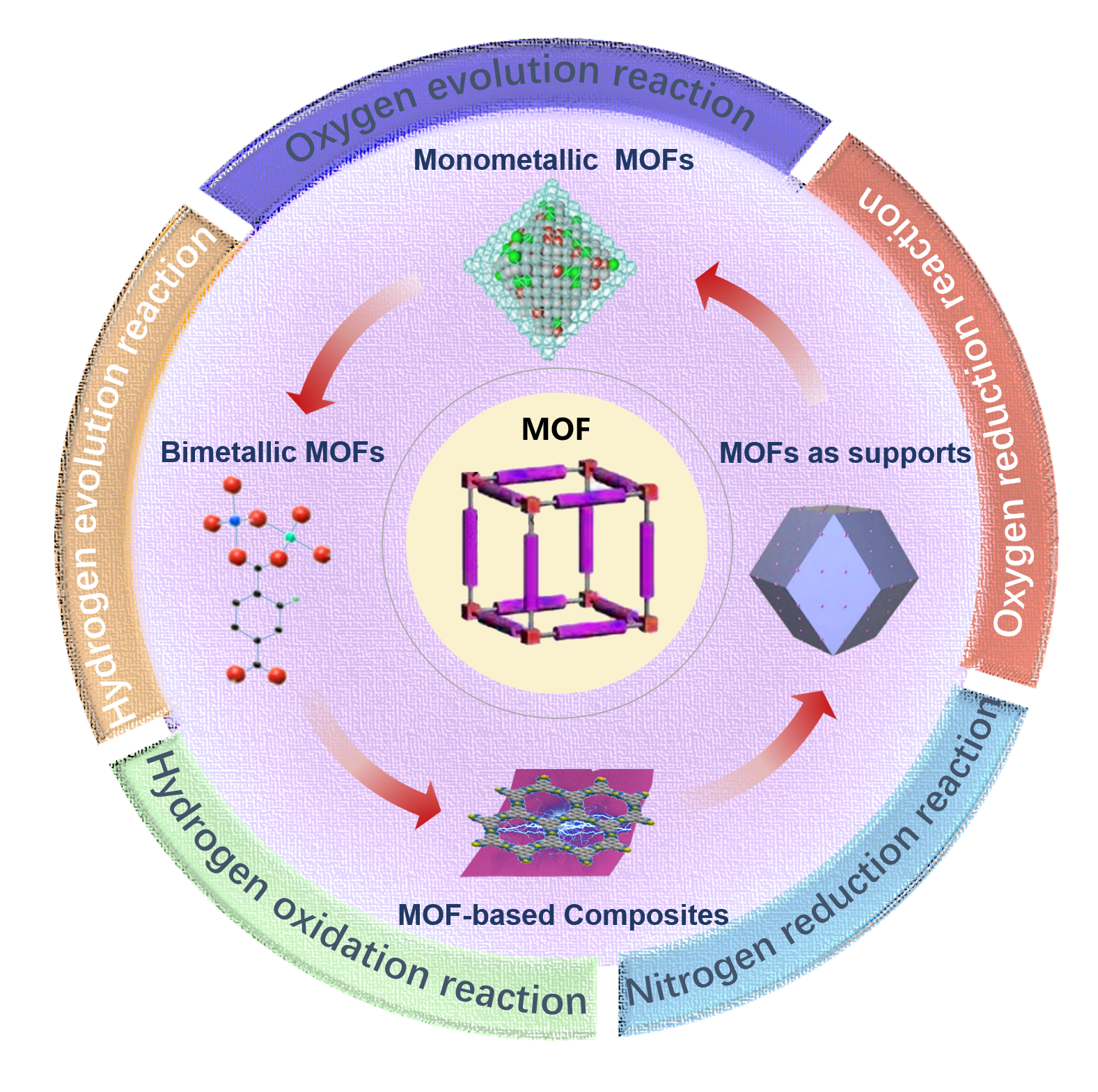

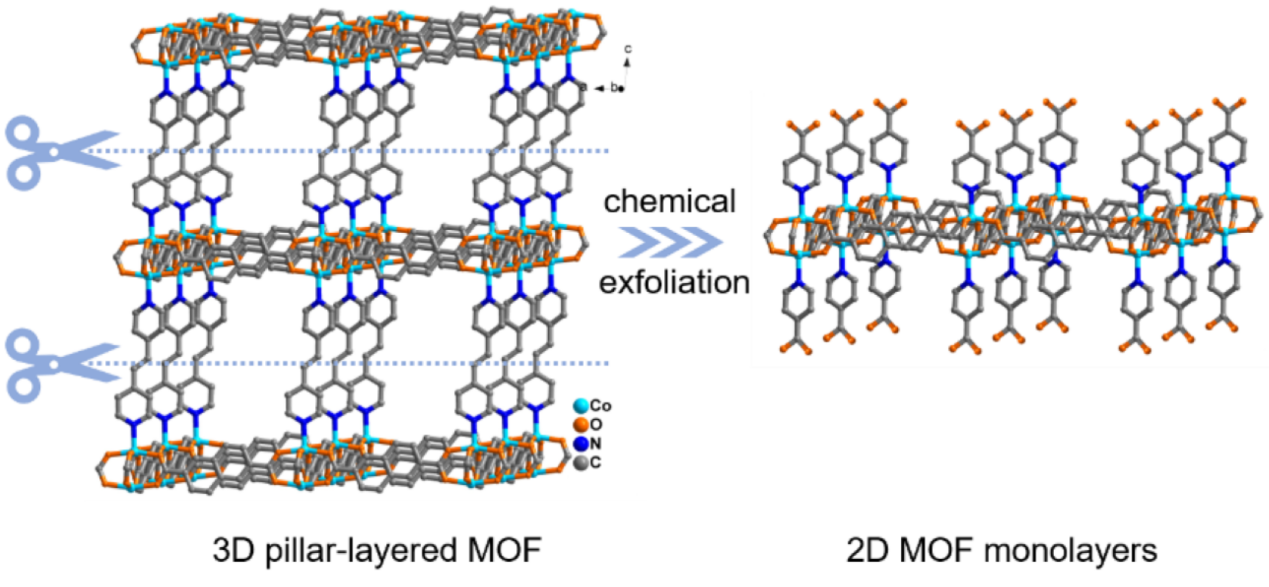

This prestigious honor recognizes Prof. Kitagawa’s pioneering contributions to the development of metal–organic frameworks (MOFs) — innovations that have revolutionized materials chemistry and opened new frontiers in gas storage and separation, chemical sensors, water harvesting and purification, heterogeneous catalysis, energy storage, and drug delivery.

His recent review on flexible MOFs has been published in ICM in July 2025:

Soft porous crystals: flexible MOFs as a new class of adaptive materials

Jiahui Guo, Sai Chu, Fangli Yuan, Ken-ichi Otake,* Ming-Shui Yao* and Susumu Kitagawa*

Read for free: https://doi.org/10.1039/D5IM00067J

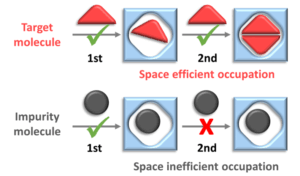

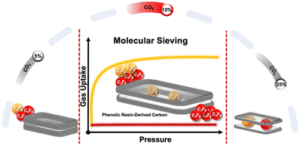

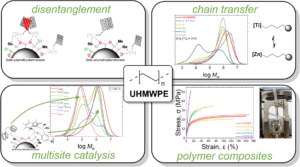

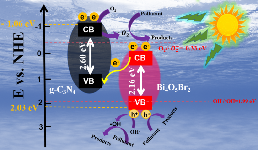

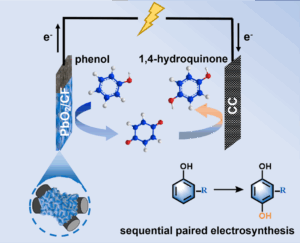

In this review, Prof. Kitagawa and co-authors summarized key advancements in SPCs across dosage-related applications, including moderate and high-dose scenarios as well as trace or low-dose ones. They emphasized the significance of “dose-sensitive” applications for “scaling softness” in industrialization. They reveal the promising applications of SPCs in fields such as gas storage and separation, catalysis, nuclear industry, and devices, providing valuable guidance for future material design and process development. This insightful review also provided an outlook on the remaining challenges to this field under real-world conditions.

This article has also been featured on EurekAlert!. Read the EurekAlert! coverage here.

Professor Susumu Kitagawa is a Distinguished Professor at Kyoto University, Japan. He is a Member of the Japan Academy (2019) and Foreign Member of the Royal Society (2023). His main research field is inorganic and material chemistry, in particular, chemistry of coordination space, and his current research interests are centered on synthesis and properties of porous coordination polymers/metal-organic frameworks. He is a pioneer in the development of metal-organic frameworks (MOFs) who was the first to discover and to demonstrate “porosity” for metal complexes with gas sorption experiments (1997).

Professor Susumu Kitagawa is a Distinguished Professor at Kyoto University, Japan. He is a Member of the Japan Academy (2019) and Foreign Member of the Royal Society (2023). His main research field is inorganic and material chemistry, in particular, chemistry of coordination space, and his current research interests are centered on synthesis and properties of porous coordination polymers/metal-organic frameworks. He is a pioneer in the development of metal-organic frameworks (MOFs) who was the first to discover and to demonstrate “porosity” for metal complexes with gas sorption experiments (1997).

Contact us: icm@rsc.org

Contact us: icm@rsc.org

Visit our website: rsc.li/icm

Find all the latest developments, research and news from across our portfolio on X (Twitter), LinkedIn, Bluesky, and sign-up to our e-alerts.

Comments Off on ICM Spotlight: A Review on Soft Porous Crystals by Susumu Kitagawa — Newly Minted Nobel Laureate 2025

Contact us: icm@rsc.org

Contact us: icm@rsc.org

Suojiang Zhang, Professor at the Institute of Process Engineering (IPE), Chinese Academy of Sciences (CAS), President of Henan University, China. He is a leading scientist in ionic liquids (ILs) and green chemical engineering who was elected as a Member of Chinese Academy of Sciences in 2015 and Fellow of the Canadian Academy of Engineering in 2024. He has published over 700 papers in Chemical Reviews, Nature Communications, Angewandte Chemie, Advanced Materials, AIChE Journal, Chemical Engineering Journal, etc., with 40,543 citations and an h-index of 97, 11 books, and 8 chapters. He holds 291 patents, including 6 United States of America/Japan patents. He has developed over 10 IL-based green technologies with successful industrial applications, such as the world’s first 200,000 t/a IL-catalyzed CO2 to dimethyl carbonate industry plant. He is a member of the Chinese Academy of Sciences and has received the TWAS Award in Chemistry, the Ho Leung Ho Lee Foundation Science and Technology Progress Award, and the 2nd Class Award for National Natural Science of China. As head of the CAS–TWAS Centre of Excellence for Green Technology and the International Green Technology Alliance, he has cultivated over 50 graduate students from Pakistan, India, Nigeria, etc., contributing greatly to exchanges and cooperation with developing countries.

Suojiang Zhang, Professor at the Institute of Process Engineering (IPE), Chinese Academy of Sciences (CAS), President of Henan University, China. He is a leading scientist in ionic liquids (ILs) and green chemical engineering who was elected as a Member of Chinese Academy of Sciences in 2015 and Fellow of the Canadian Academy of Engineering in 2024. He has published over 700 papers in Chemical Reviews, Nature Communications, Angewandte Chemie, Advanced Materials, AIChE Journal, Chemical Engineering Journal, etc., with 40,543 citations and an h-index of 97, 11 books, and 8 chapters. He holds 291 patents, including 6 United States of America/Japan patents. He has developed over 10 IL-based green technologies with successful industrial applications, such as the world’s first 200,000 t/a IL-catalyzed CO2 to dimethyl carbonate industry plant. He is a member of the Chinese Academy of Sciences and has received the TWAS Award in Chemistry, the Ho Leung Ho Lee Foundation Science and Technology Progress Award, and the 2nd Class Award for National Natural Science of China. As head of the CAS–TWAS Centre of Excellence for Green Technology and the International Green Technology Alliance, he has cultivated over 50 graduate students from Pakistan, India, Nigeria, etc., contributing greatly to exchanges and cooperation with developing countries. Contact us:

Contact us:

Professor Susumu Kitagawa

Professor Susumu Kitagawa

Contact us:

Contact us: