Pollutants enter the ecosystem through several pathways. Dangerous substances are released into the atmosphere in many ways, for instance by car exhausts, from industrial fumes and drainage effluents and through degradation of pesticides to name but a few.

Pollutants enter the ecosystem through several pathways. Dangerous substances are released into the atmosphere in many ways, for instance by car exhausts, from industrial fumes and drainage effluents and through degradation of pesticides to name but a few.

A contaminant that appears to be ubiquitous and released through all these pathways is phenol. Phenols are highly toxic by inhalation, causing lung edema, through ingestion, damaging kindneys, brain and liver, and it is also an extreme irritant to the skin, causing severe burns. Some phenols are reported carcinogens.

Degrading and removing phenols from contaminated water is essential before allowing it to enter the ecosystem. Many techniques have been developed and applied in order to do this, such as the use of polymeric resins, microbial or enzymatic degradation, adsorption and other catalytic chemical transformations.

A recently published work by Yao, Shi and Sui focused on the latter.

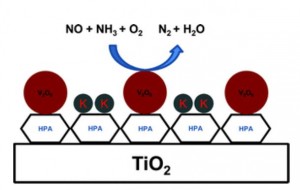

The group focused on the use of supported titania for the photocatalytic degradation of phenols under UV light in aqueous solutions. The catalyst was prepared by anchoring TiO2 onto fly ash deriving from municipal waste combustion: a less usual support compared to the more widespread silica, alumina and zeolites.

The fly ash was treated with acid, washed and dried before the titanium oxide coating was applied as a sol-gel and the material calcinated. Several calcination temperatures were tested, finding that 500 °C provided the ideal condition to obtain high degree of crystallinity in the catalyst.

The catalytic loading was also explored in the range 10-30 g/L to determine the highest concentration achievable without preventing light from reaching the bulk of the solution; the catalyst also proved robust and reusable, retaining 90% of its photocatalytic activity even after 4 cycles. Several tests were peformed to ensure that the activity of the system was due to the photocatalyst, including test runs with untreated fly ash, only titania and UV irradiation alone.

To better understand the characteristics of the system, a kinetic study of the degradation reaction was also performed, revealing a first order-like behaviour; also, a three-step mechanism for the fly ash-supported catalyst was proposed.

Using the optimal conditions found during the study, the group achieved 94 % of phenol degradation with a catalyst loading of 20 g/L over 4 hours of irradiation, which, with its reusability, could make the catalyst potentially employable for continuous use in water treatment.

Read more about this catalyst here.

Application of fly ash supported titanium dioxide for phenol photodegradation in aqueous solution

Zhongliang Shi, Shuhua Yao and Chengcheng Sui

Catal. Sci. Technol., 2011, Advance Article

DOI: 10.1039/C1CY00019E