S.J.Samuel Justin1, P.Wilson1

1Department of Chemistry, Madras Christian College

Email: sam310just@gmail.com, wilson@mcc.edu.in

Why is this useful?

Spin-coating is a highly reproducible, simple, time-efficient, and cost-effective coating technique is widely employed technique for the fabrication of thin-film coatings over large areas with smooth and homogeneous surfaces [1]. It has been widely used for the production of monolayer- and multilayer-thin coatings, freestanding (FS) nanosheets and membranes, for various industrial and biomedical applications, e.g. mitigation of corrosion [2], wound dressings, cell culture substrates, and as drug delivery devices.

A tip to develop portable spin coaters by recycling computer fans and mobile phone wall chargers was previously presented [3]. Using adhesive strips to secure a metal alloy sample on the center of the computer fan often slips and knocked down while trying to remove the sample after the coating process. This affects the coating and thereby a proper substitute to hold the sample tight during the spin and at the same time easier to remove it after the coating is essential. In addition, the sample spinning at high rpm levels expels the excess coating substrate away from the system which has to be addressed in order to prevent the contamination of the surroundings. In this regard an improved form of portable spin coater is proposed and presented.

What do I need?

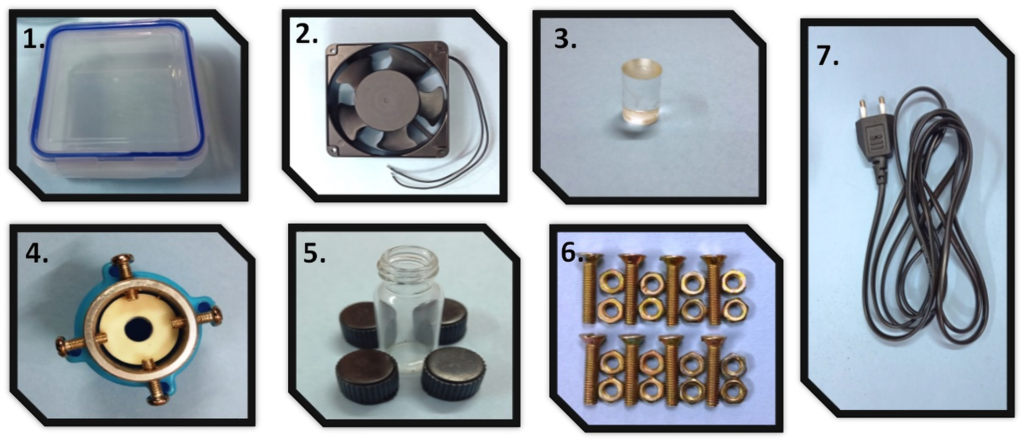

Parts for the spin coater

- Polycarbonate container, Dimensions 155 X 155 X 60 mm

- Panel cooling fan 120 x 120 x 38 mm with 2800 rpm

- Acrylic support rod of length 15 mm and diameter of 12 mm

- Faucet water tap adapter

- Black cap of 5mL clear round glass bottle – 4 pieces

- 8 pieces set of 3mm diameter round head 20 mm bolt and nut

- Power cable

Parts and chemicals for the specific examples

- Nitro cellulose lacquer

- Aluminium alloy 15mm x15mm x6mm

What do I do?

Assembling of spin coater

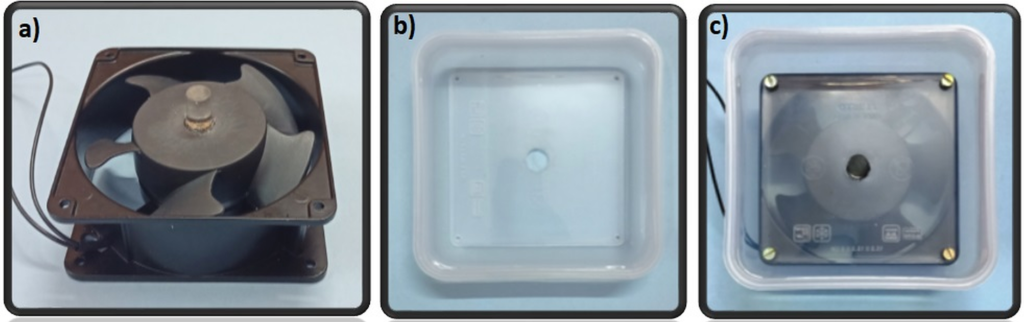

- The acrylic rod is fixed at the centre of the fan using instant cyanoacrylate ester adhesive (Fig.a)

- A hole of 15 mm dia. is drilled at the centre of the container base and 2.8 mm hole at the four corners of the container (Fig.b).

- The container is placed over the fan and the corners are fixed using bolt and nut (Fig.c)

- The stem of the faucet water tap adapter was cut and the hole is enlarged to 12mm dia. It is then fixed using instant adhesive on the top of the acrylic rod (Fig.d, e & f)

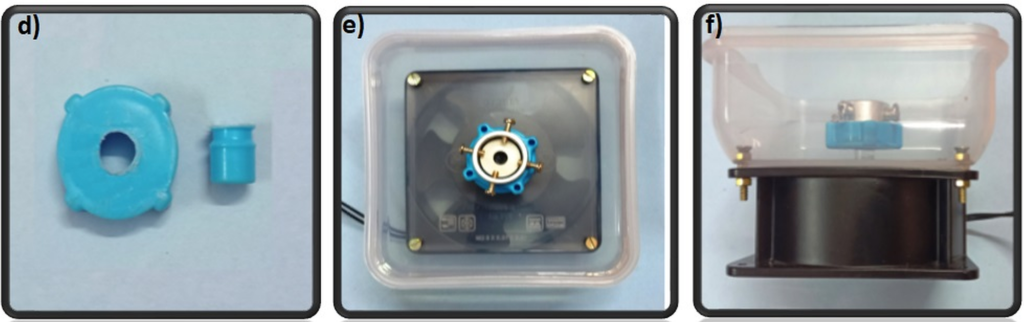

- The black caps were drilled at the center to create a hole of 2.8mm dia. The bolt is inserted from below each cap and then tightened with the base of the cooling fan at the four corners (Fig. g and h).

- The power cable is attached to the fan (Fig. i)

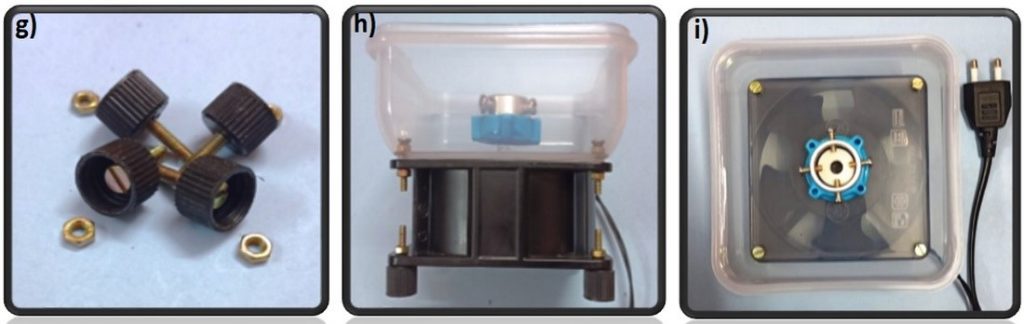

- The lid of the container is drilled at the center to 15mm dia. which acts as a space for dropping the coating material (Fig. j and k) and the final product is displayed in (Fig. l).

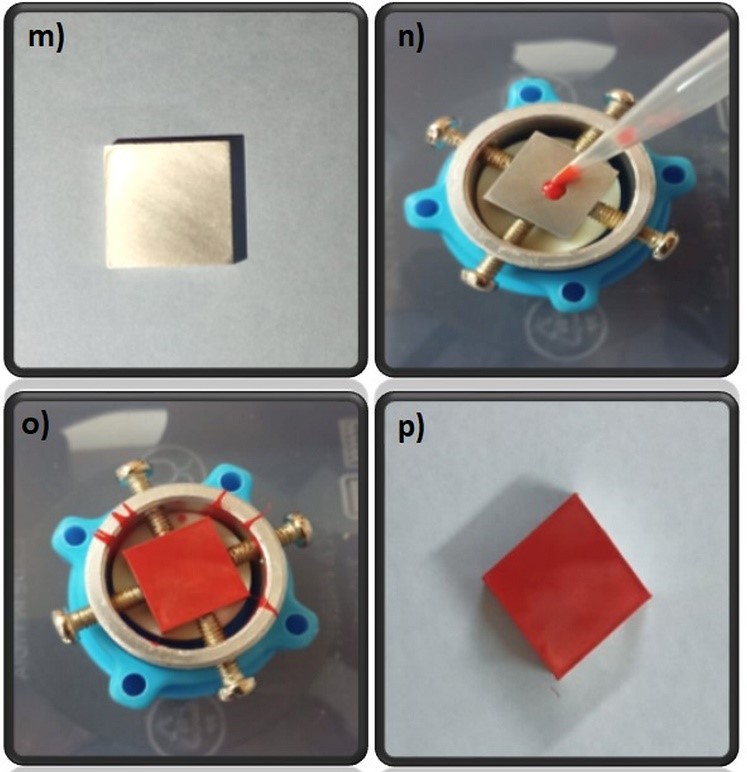

- The liquid containing the coating material (pigmented nitrocellulose lacquer) is placed on top of the substrate (Aluminium alloy) (Fig. m) by using a (micro) pipette (Fig. n.)

- The fan is turned on and the substrate is spin coated for about 30 seconds (Fig. o) (time can vary depending on the substrate viscosity and coating thickness required). The coated substrate (Fig. p) is subjected to further evaluation.

References:

[1] Moreira, Joana, A. Catarina Vale, and Natália M. Alves. “Spin-coated freestanding films for biomedical applications.” Journal of materials chemistry B 9, no. 18 (2021): 3778-3799.

[2] Telmenbayar, Lkhagvaa, Adam Gopal Ramu, Daejeong Yang, Minjung Song, Tumur-Ochir Erdenebat, and Dongjin Choi. “Corrosion resistance of the anodization/glycidoxypropyltrimethoxysilane composite coating on 6061 aluminum alloy.” Surface and Coatings Technology 403 (2020): 126433.

[3] A second life for old electronic parts: a spin coater for microfluidic applications, https://blogs.rsc.org/chipsandtips/2018/04/25/a-second-life-for-old-electronic-parts-a-spin-coater-for-microfluidic-applications/ (accessed August 2020)