Lorenzo Capretto1, Stefania Mazzitelli2, Stefano Focaroli2 and Claudio Nastruzzi2

1 School of Engineering Sciences, University of Southampton, UK

2 Department of Chemistry and Technology of Drugs, University of Perugia, Perugia, Italy

Why is this useful?

Common ways to link microdevices with standard fluidic equipments (such as syringe or peristaltic pumps) are based on the use of nanoports, created by: hand screwing a tube in the substrate material, gluing the tube fitting directly on the microfluidic device or commercial nanoports.

However, when such types of connection are used, there might be a series of potential issues, including: possible leakage of liquid from the connections, especially when high pressure inlet are required, possible clog of the port when glue is used or the high cost of the commercial devices.

Here, we demonstrate an easy and effective way for the creation of cheap and tight microfluidic connection ports for a varied range of substrate material including glass, silicon and polymers. Our approach solves the issues reported above with the creation of and inexpensive, well tight and glue-free port based on a “wall plug inspired” effect.

What do I need?

- Plastic tube (ETEF, FEP or PTFE) 1/16″ OD, 0.75 mm ID [1]

- 21 gauge hypodermic needle [2]

- Drilling bit 1.5 mm [3]

- A Proxxon, table top, micro miller [3] or any other handheld power tool

- A cutting disc made of a hard abrasive [3] or any other tool for cutting the needle

Fig. 1. Tubing used for the production of “wall plug inspired” connectors for macro to microfluidic interfacing: FEP (fluorinated ethylene-propylene) tube (A) and hypodermic needle with Luer-Lock (21 gauge) (B).

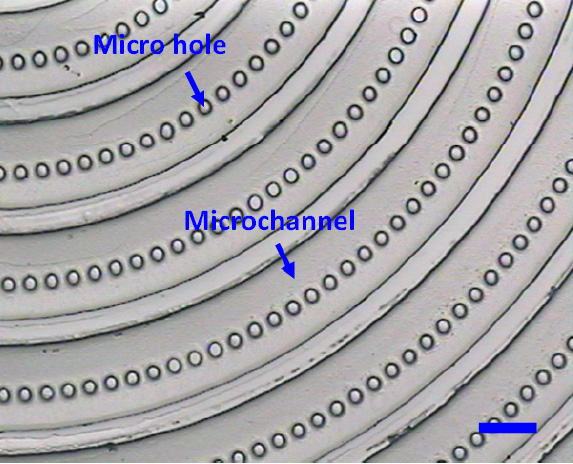

Fig. 2. Stereo photomicrographs of the FEP tube (A), the hypodermic needle (B), the hypodermic needle inserted into the FEP tube (C) and the bit used for drilling the microfluidic chips (D). Note the different (crucial) sizes as determined by photomicrograph analysis. External diameter of the FEP tube: 1.58 mm (red arrow); internal diameter of the FEP tube: 0.76 mm (magenta arrow); external diameter of the 21 gauge needle: 0.82 mm (yellow arrow); external diameter of the FEP tube after insertion of the hypodermic needle: 1.66 mm and finally, diameter of the bit used for drilling the microchips: 1.5 mm (white arrow).

What do I do?

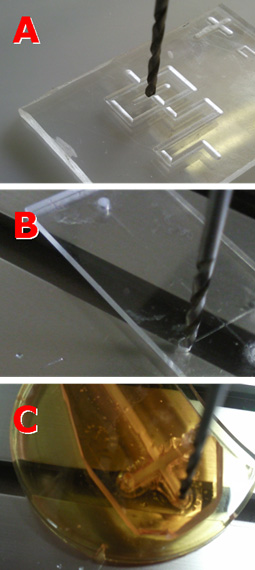

1. First drill the hole on the microfluidic device you wish to connect.

Fig. 3. Drilling process on different materials, namely: commercial TOPAS® COC (A) and custom made poly(methyl methacrylate) (PMMA) (B) or epoxy resin (C) chips.

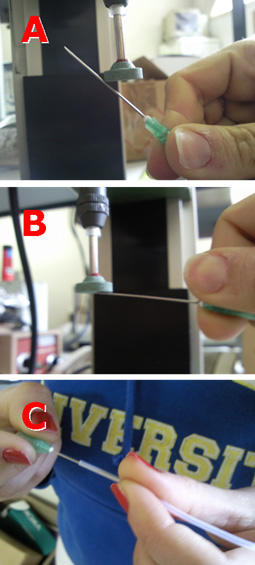

2. Cut the needle and pre-insert it in the plastic tube.

Fig. 4. Assembly of the”wall plug inspired” connectors. Cutting (A), sanding (B) and insertion (C) of the needle into the FEP tube.

3. Assemble the port and tighten it in the previously drilled hole by inserting the needle in the tube. The needle must be inserted deeper than the interface between tube and hole in order to leverage the wall plug effect.

Fig. 5. Insertion of the finished “spit inspired nanoport” into different chip type, namely: commercial TOPAS® COC (A) and custom made epoxy resin (B) or polydimethylsiloxane (PDMS) (C) chips

Fig. 6. Schematic representation of the assembling of “wall plug inspired” microfluidic ports.

References

[1] http://www.upchurch.com

[2] http://www.artsana.com

[3] http://www.proxxon.com