Johnny J. Perez and Jonathan G. Shackman

Department of Chemistry, Temple University, Philadelphia, PA, USA 19122

Why is this useful?

A critical step in fabrication of microfluidic devices is coupling with the macroscopic world. Reservoirs or pressure fittings are frequently adhered to devices by liquid epoxies or heat cured adhesive rings, such as supplied with commercial Upchurch Scientific (Oak Harbor, WA, USA) NanoPorts. Liquid methods can potentially enter the device and clog channels. Non-tacky resin rings make alignment of critical fittings and O-rings difficult, as they are inert until heat cured. As an alternative to PDMS-based interfacing [1,2,], we describe a simplified method for forming customized, tacky adhesive rings using 3MT VHBT pressure-sensitive tape (Fig 1). The rings are similar to the now discontinued NanoPort rings formed from 3MT 583 tape [3], but can cure at room temperature. We have tested NanoPorts using these rings underwater on both polycarbonate and glass substrates in excess of 40 psi with no failures. The cost per ring (assuming a 1 cm diameter) is a few US pennies. Rings can easily be peeled from the ports and substrate after applying sufficient torque or sheer forces without leaving residues, facilitating aggressive cleaning (such as in piranha solution) of clogged microchannels.

What do I need?

The materials needed are shown in Figure 2 and include:

- 3MT VHBT tape. We use 0.5″ wide VHBT 4926, but a variety of tapes (including 3MT 583 tape) could be used, with selectable adhesion qualities and solvent resistances.

- Gasket Punch or Cork Borers. Cork borers (commonly used in chemistry labs) require two cuts while dual cutting punches, such as available from McMaster-Carr (Elmhurst, IL, USA), cut both inner and outer rings simultaneously. We use 3/16″ inner and 7/16″ outer diameter punches for NanoPort rings.

- Hammer and pad. A piece of scrap wood can be used for a cutting pad.

- Forceps. Fine tips aid in ring manipulation and removing the adhesive backing.

- Ports and microchip. Homemade or commercial ports and chips can be used with the method. The glass device used for demonstration was made using previous protocols [4].

- Binder clip. The tape requires at least 10 psi for strong bonds and pressure should be maintained during curing. Mini-vises or C-clamps can also be used for hard to reach ports [3].

- Oven (optional). VHBT tape can cure overnight at room temperature or in 1 hr at 60 to 90 °C.

What do I do?

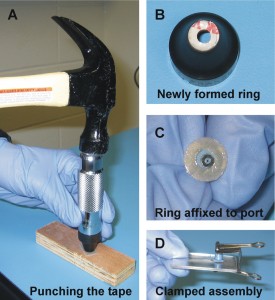

The sequence is shown in Figure 3. The following specifics can easily be modified for a given application.

1. Clean ports / O-rings in DI water followed by methanol or isopropanol. It is assumed the microdevice is clean after fabrication but can also be carefully cleaned.

2. Cut a 1 cm length of tape and place the sticky side on the punch.

3. Place the end of the punch/tape on a pad or wood block and hit the opposite end of the punch with a hammer (Fig 3A).

4. The ring will likely remain in the punch, with the backing side facing out (Fig 3B). Use forceps to remove the newly formed ring and attach the exposed tacky side to the port. Pressing the port (prior to removing the backing) against a flat surface can help adhesion.

5. Remove the backing with forceps to expose the other tacky side (Fig 3C) and align the assembly with the microchip access hole.

6. Clamp the port and microfluidic device using a binder clip or clamps (Fig 3D).

7. Cure either overnight or for 1 hr in an oven at 60 to 90 °C.

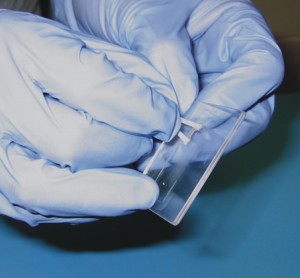

8. Adhered ports can be removed by either twisting and tilting or tightening a nut longer than the port to lift the port off the substrate. The remaining ring can be removed using forceps to lift an edge and peeling (Fig 4).

What else should I know?

Rings should be made as needed to prolong shelf life (VHBT on the roll lists a 2 yr life when stored at room temperature and 50% relative humidity) [5]. While suitable for aqueous solutions, prolonged use of organic solvents is not recommended with VHBT tape [6], and an alternative adhesive or method, such as described by Watson and Wheeler [1], is suggested. Application of high torque will cause the rings to fail, as can occur when over-tightening pressure fittings.

References

[1] M. W. L. Watson, A. R. Wheeler, Organic solvent compatible reservoirs for glass microfluidic chips, Chips & Tips, (Lab on a Chip), 12 December 2007

[2] J. Greener, W. Li, D. Voicu, E. Kumacheva, Reusable, robust NanoPort connections to PDMS chips, Chips & Tips, (Lab on a Chip), 24 October 2008

[3] C. Koch, J. Ingle, V. Remcho, Bonding Upchurch® NanoPorts to PDMS, Chips & Tips, (Lab on a Chip), 15 February 2008

[4] N.I. Davis, M. Mamunooru, C.A. Vyas, J.G. Shackman, Anal. Chem., 2009, 81, 5452-5459.

[5] 3MT VHBT Double Coated Acrylic Foam Tapes – June 2009 Data Sheet

[6] 3MT VHBT Durability – March 2001 Bulletin