Jian Hua Han, Shao Hua Li, Zhong Han Sheng and Long Jiang

Key Laboratory of Colloid and Interface, Institute of Chemistry, Chinese Academy of Sciences (ICCAS), Beijing, China

Why is this useful?

We demonstrate a reversible bonding method to fabricate microscope slide glass chips. This method involves pre-curing a PDMS polymer layer to form a highly adhesive glue which strongly bonds glass chips. Traditional bonding methods[1-4] are either irreversible or not very strong; our approach solves this problem. The glass chips made by our approach can bear high fluid pressure without leakage and can easily be disassembled and reassembled when clogging happens. Our method is suitable for any ordinary labs that lack expensive equipment to fabricate microfluidic chips.

What do I need?

- Microscope slides and PDMS kits (SYLGARD®184), produced by Dow Corning. The silicone elastomer base and curing agent were mixed well at the ratio of 10:1 to form a paste before use.

- Craft knife, scalpel, plastic wrap, etc.

- Microscope slides chip with patterns and appropriately located inlet and outlet holes.

What do I do?

First, prepare a microscope slide chip using standard wet etching methods[5] and drill holes. Then execute the following 5 steps:

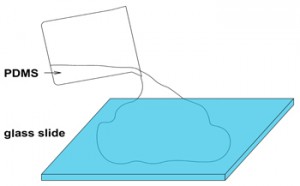

1. Pour the PDMS (elastomer mixed with curing agent and degassed) onto a glass slide, see figure 1.

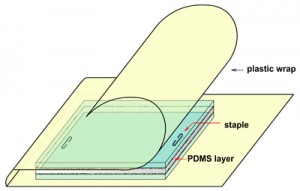

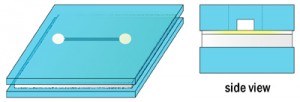

2. Place another glass slide onto the PDMS of step 1 carefully, avoiding any bubbles during the process. Use a staple as a spacer, and wrap the sandwich in plastic wrap to avoid leakage of PDMS. See figure 2.

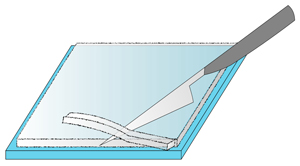

3. Cure the PDMS to a solid state, then pry up the upper slide. Use a scalpel to trim the PDMS layer to size, see figure 3.

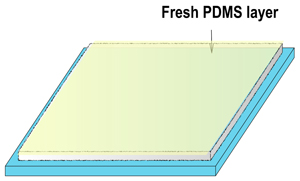

4. Spin coat a fresh PDMS layer 1µm thick onto the PDMS layer of step 3 at the rate of 3000 RPM, then pre-cure for 20min at 80°C to form a hard glue, see figure 4.

5. Place the glass slide chip (with patterns and appropriately located inlet and outlet holes) onto the PDMS layer of step 4, then continue to cure the polymer to a solid state, and the microfluidic chip is formed, see figure 5.

What else should I know?

The method presented above is a useful method for rapid fabrication of microfluidic chips. The advantages of this method are as follows:

- does not need a strictly flat surface, very cheap microscope slides are available

- high contact bonding strength, does not rupture under high pressure (280kPa), while commonly used devices cannot withstand fluid pressures of more than 100kPa

- the chip can be opened with a craft knife when clogging happens and can be reused many times

The limitation of this method is that you must be careful when placing the etched glass slide onto the uncured PDMS layer – avoid too much pressure on it since this could lead to squeezing of PDMS into the channels and clogging of the chip.

Acknowledgements

This research is funded by the Chinese Academy of Sciences (grant number KJCX2-YW-H18) and the National Sci-Tech Special Item for Water Pollution Control and Management (2009ZX07 5287- 007 – 03).

References

[1] N. Miki, Sensor Letters, 2005, 3, 263-273

[2] A. Sayah, D. Solignac, T. Cueni and M. A. M. Gijs, Sensors and Actuators A: Physical, 2000, 84, 103-108

[3] S. Shoji, H. Kikuchi and H. Torigoe, Sensors and Actuators A: Physical, 1998, 64, 95-100

[4] N. Chiem, L. Lockyear-Shultz, P. Andersson, C. Skinner and D. J. Harrison, Sensors and Actuators B: Chemical, 2000, 63, 147-152

[5] M. Castano-Alvarez, D. F. Pozo Ayuso, M. Garcia Granda, M. T. Fernandez-Abedul, J. Rodriguez Garcia and A. Costa-Garcia, Sensors and Actuators B: Chemical, 2008, 130, 436-448