Jie Xu and Daniel Attinger

Laboratory for Microscale Transport Phenomena, Department of Mechanical Engineering, Columbia University, New York, NY 10027, USA

Why is this useful?

Assembling multiple layers by bonding or lamination is a simple way to manufacture complex multilayer microfluidic chips [1, 2]. However, bonding or lamination of chambers with large aspect ratio, i.e. wide and shallow, sometimes fails because of sagging. Figure 1 illustrates a sagging problem, which resulted in the top chamber wall being accidentally bonded to the bottom wall. Here, we describe a tip to prevent sagging by using regular cooking salt.

What do I need?

- Cooking salt (grain size: normally 300 microns, can be further ground to less than 100 micron; melting temperature: 801 °C, good for lamination)

- Precision tweezers

- Stereomicroscope

What do I do?

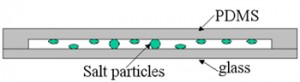

1. Carefully pave the bottom of the chamber with ordinary salt as in Figure 2. Try to perform this action using fine tweezers under a stereomicroscope, if the chamber is too small.

2. Plasma bond or laminate the top layer. Be careful during handling, so that the salt does not end up in your DRIE machine.

3. After bonding is done, flush the microfluidic system with deionized water for several minutes to dissolve and remove salt particles. As figure 4 shows, the bonded chamber does not exhibit adhesion between the top and bottom wall.

References

1. J. Xu and D. Attinger, Drop on demand in a microfluidic chip, J. Micromech. Microeng., 2008, 18, 065020.

2. P. J. Hung, P. J. Lee, P. Sabounchi, N. Aghdam, R. Lin, and L. P. Lee, A novel high aspect ratio microfluidic design to provide a stable and uniform microenvironment for cell growth in a high throughput mammalian cell culture array, Lab Chip, 2005, 5, 44-48.