Jeonggi Seo and Meng H. Lean

Palo Alto Research Center, Palo Alto, CA, USA

Why is this useful?

Syringes are commonly used to supply or collect liquid samples for microfluidics. However, interfacing between a microfluidic chip and syringe is problematic due to their size difference. Plastic tube connectors or Luer stubs have been used as interfacing methods, but they increase sample dead volume and thus experimental cost. The goal of this tip is to provide an inexpensive and simple interface, with minimized sample dead volume, between a microfluidic device and syringe.

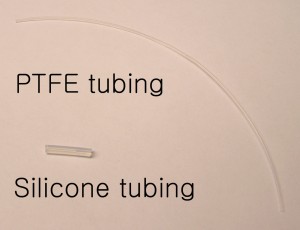

Figure 1.

What do I need?

- 18 gauge blunt needle

- PTFE microbore tubing (0.012″ID x 0.030″OD, Cole Parmer)

- Silicone (platinum-cured) tubing (1/50″ID x 1/12″OD, Cole Parmer)

- B-D Disposable Syringes 1 mL

What do I do?

1.Punch access holes into your PDMS device with an 18 gauge blunt needle.

2.Cut a segment of silicone tubing ~10 mm long. (Figure 1)

3.Cut a segment of PTFE microbore tubing with desirable length for your set-up.

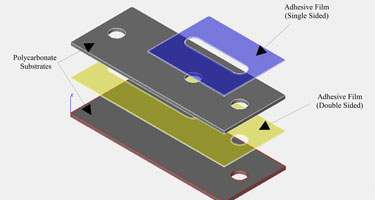

Figure 2.

4.Insert the piece of silicone tubing inside the 1 ml syringe tip. Make sure the silicone tubing reaches the inner chamber of the syringe but doesn’t disturb piston movement. (Figure 2a-c)

5.Insert the PTFE tubing into the inserted silicone tubing. (Figure 2d)

6. Load your sample into the syringe

7. Insert the free end of the PTFE tubing into the access hole on your PDMS device (Figure 3). Since no adhesive is involved, the PTFE tubing can be disposed of or reused after cleaning.

References

S. Mohanty, G. Mensing and D. J. Beebe, PDMS connectors for macro to microfluidic interfacing, Chips & Tips (Lab on a Chip), 23 October 2006.