We are very pleased to present RSC Sustainability’s themed collection on Energy Materials Redesign, Reuse and Repurpose.

Read the collection now: https://rsc.li/su-energymaterials

As the world moves away from using fossil fuels to produce energy, demand for alternative materials is increasing. In order to ensure a sustainable supply of energy materials in the future, it is vital that they can be recycled and used again. This collection highlights research that aims to make this a reality.

The collection showcases work in 3 broad categories: 1) redesigning materials and processes to increase device lifetime, 2) reuse and repurpose of waste as a secondary source, and 3) recycling of end-of-life devices to reduce waste generation.

Read the Editorial from the Guest Editors here: https://doi.org/10.1039/D4SU90068E

Explore some of the highlights from the collection with comments from the authors themselves:

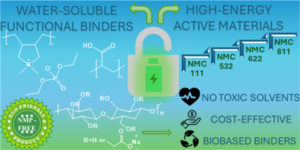

Mecerreyes, Pozo-Gonzalo, et al, RSC Sustain., 2024, 2, 2125-2149

This article highlights how polymer binders are key in the development of green and high energy batteries. It summarizes the recent advances in aqueous processing of NMC cathodes in high-voltage Li-ion batteries.

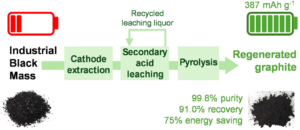

Recovery of graphite from industrial lithium-ion battery black mass

Titirici, et al, RSC Sustain., 2025, 3, 264-274

While significant attention is given to metal extraction from Li-ion battery cathodes, graphite anodes are often overlooked, despite being a critical resource facing a projected supply shortage. Our research focuses on recovering graphite from industrially sourced black mass, addressing real-world challenges and exploring efficient regeneration methods. These methods are designed to integrate seamlessly with existing metal recovery processes, offering practical solutions for the recycling industry.

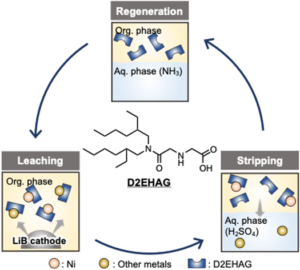

Non-aqueous dir ect leaching using a reusable nickel-selective amic-acid extractant for efficient lithium-ion battery recycling

ect leaching using a reusable nickel-selective amic-acid extractant for efficient lithium-ion battery recycling

Goto, et al, RSC Sustain., 2025

With the increasing demand for electric vehicles, the recycling of lithium-ion batteries (LiBs) becomes crucial. However, there are concerns surrounding traditional recycling methods for LiBs regarding their high environmental impact. This study aims to develop an environmentally friendly LiB recycling process surpassing conventional methods. The proposed approach eliminates the need for inorganic acids, simplifying the process. Upon realization, this process will contribute to society in various aspects, including environmental, economic, and social aspects. This process aligns with SDGs 7, 11, and 13.

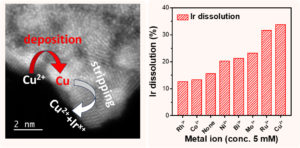

Enhanced electrochemical di ssolution of iridium oxide in acidic electrolytes through presence of metal ions: shortened lifetime and hope for recovery

ssolution of iridium oxide in acidic electrolytes through presence of metal ions: shortened lifetime and hope for recovery

Sharma, Andersen, et al, RSC Sustain., 2024, 2, 2225-2238

Electrochemical dissolution of iridium oxide is not only a vital degradation mechanism but also an innovative methodology for iridium recycling. The current work is a showcase on manipulation of metal ions to stimulate the dissolution process.

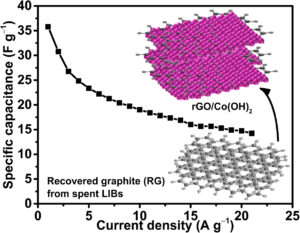

Reduced graphene oxide from dead Li-ion batteries with β-Co(OH)2 as a potential electrode for enhanced charge storage capabilities

Reduced graphene oxide from dead Li-ion batteries with β-Co(OH)2 as a potential electrode for enhanced charge storage capabilities

Viswanathan and Aravindan, RSC Sustain., 2024, 2, 2199-2212

Everybody can’t produce energy but save it, the energy that you save is the energy that you produce. Supercapacitors are the future energy savers, better we recycle the batteries to make them.

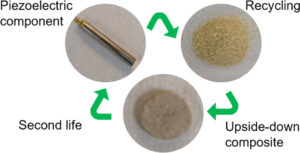

Bai, et al, RSC Sustain., 2024, 2, 961-974

Although we are moving towards greener piezoelectric components in the next-generation manufacturing, the older generation has left us a tremendous number of devices containing hazardous elements. We should not let them expose to the nature but rather should recycle them and give them a second life in lower-end products that may accept compromised functionality, to save resources for the new manufacturing for higher-end products.

We hope you found exploring this collection both enjoyable and rewarding. If you have work on recycling energy materials that you would like to publish, submit to RSC Sustainability now at https://mc.manuscriptcentral.com/rscsus