Environmental impacts of oil spills

Accidental oil spills are unavoidable during the acquisition, processing and distribution of petroleum products. Oil can pollute the oceans through a range of processes, such as land run off, tanker discharges and vessel accidents. Oil spills impact humans, plants and wildlife, including fish, mammals and birds.

In many cases, the environmental recovery after an oil spill is fairly swift and complete within ten years; however, some long-term environmental effects can be measured decades after a large oil spill.

Oil slick in the Gulf of Mexico, April 29th 2010 (Image from NASA Goddard Space Flight Center)

Oil spill remediation techniques

Remediation techniques to manage oil spills are often both expensive and lengthy. Conventional clean-up techniques after oil spills range from in situ burning; mechanical methods, such as booms, vacuums and skimming; chemical dispersants; and/or the use of sorbent materials. Each of these methods presents its own advantages and disadvantages depending on the scenario of the oil spill.

One of the most versatile, cost effective and fruitful methods is to use porous sorbent materials to remove oil from the water surface. We can find natural oil sorbents such as wood, cotton, milkweed, and wool, among others. The efficiency of the sorbent material is related to its hydrophobicity, porosity, sorption capacity and rate, and reusability.

Each oil remediation technique comes with its own environmental impact. Many novel synthetic oil sorbents are currently being developed and there is great need for biodegradable and reusable absorbents to manage oil spills – and to minimize the environmental effect of the oil remediation technique.

New methods to separate oil and water: biodegradable synthetic oil sorbent

A study from Boston University recently published in Environmental Science: Water Research & Technology presents knowledge on biodegradable synthetic oil sorbents, allowing for efficient recovery after accidental oil spills.

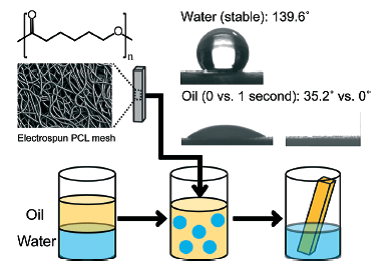

Electrospun non-woven poly(ε-carporlactone) PCL microfiber meshes are mechanically robust, reusable and biodegradable polymeric oil sorbents capable of retrieving oil from oil spills in both freshwater and seawater.

Schematic diagram of an electrospun hydrophobic PCL mesh that selectively removes oil from a water-in-oil emulsion.

By simulating oil spills in fresh- and seawater scenarios, researchers examined how well the polymeric oil sorbent could retrieve oil. The PCL is hydrophobic and has >99.5% (oil over water) oil selectivity and has oil absorption capacities of approx. 10 grams of oil/gram of sorbent material. Both the absorption capacity and the oil selectivity remained constant over several oil absorption and vacuum assisted retrieval cycles when removing crude oil or mechanical pump oil.

This study shows the need for biodegradable synthetic oil sorbents which balance porosity and mechanical integrity enabling reuse, and allowing for efficient recovery of oil after an oil spill.

Interested in this research? You can read the full paper for free* using the link below:

Poly(ε-caprolactone) microfiber meshes for repeated oil retrieval

J.S Hersey, S.T Yohe and M. W. Grinstaff

Env. Sci: Water Res. Technol. 2015, 1, 779-786

DOI: 10.1039/C5EW00107B

—————-

Jesper Agrelius is a MSc student in Environmental Science at Linköping University, Sweden. His main interests regards environmental science, especially climate change and biogeochemistry. You can follow him on Twitter @JesperAgrelius.

—————-

*Access is free through a registered RSC account – click here to register