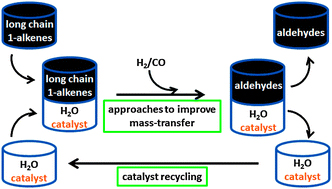

Hydroformylation (or the oxo process) is an important industrial procedure which combines alkenes with carbon monoxide and hydrogen to produce aldehydes, which are easily hydrogenated to alcohols and then plasticizers or detergents. Hydroformylation is used to produce around 9 million tons of aldehyde per year world-wide and is one of the largest industrial applications of homogeneous catalysis.

Catalyst recycling is highly desirable to reduce costs and was effectively implemented for short chain alkenes with the development of the aqueous biphasic Ruhrchemie/Rhone-Poulenc (RCH/RP) process, however due to mass-transfer limitations the application of this process is constrained to the short chain hydrocarbons. This Hot Perspective by Lorenz Obrecht, Paul C. J. Kamer and Wouter Laan details some of the alternative approaches which have been developed for the aqueous–organic biphasic hydroformylation for higher alkenes.

Alternative approaches for the aqueous–organic biphasic hydroformylation of higher alkenes

Lorenz Obrecht, Paul C. J. Kamer and Wouter Laan

Catal. Sci. Technol., 2013, Advance Article