According to the USDA foreign agriculture service, the European Union consumed 13.8 billion litres of biodiesel in 2012. The increasing demand for biodiesel stems from its lower greenhouse gas emissions, estimated to be 57% lower than emissions from burning petroleum diesel. To become competitive with fossil fuels, alternative energy sources must achieve low production costs starting from abundant feedstocks.

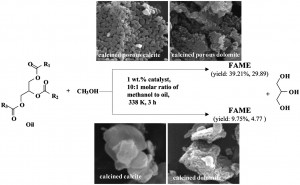

In this Advance Article, Yang and co-workers reports the transesterification of several oils to biodiesel (primarily fatty acid methyl ester, FAME), obtaining >97% yields using 3 wt% calcined porous calcite or dolomite catalysts. Prepared through simple thermal decomposition of cheap Mg/Ca carbonate minerals and stearic acid mixtures, these heterogeneous catalysts possess high special surface areas (SSAs) increasing the sites accessible for reactivity.

The researchers found that the catalysts could be regenerated by treatment with stearic acid, and re-used with no appreciable loss in activity. The authors propose that this process could be well-suited for industrial application as it is inexpensive and environmentally benign.

Read the full article here:

Rui Wang. Hu Li, Fei Chang, Jiafeng Luo, Milford A. Hanna, Daoyang Tan, Deyu Hu, Yuping Zhang, Baoan Song, and Song Yang

Catal. Sci. Technol., 2013, DOI:10.1039/C3CY00129F

Tien Nguyen is a web contributor working towards her PhD in David Nicewicz’s research group at the University of North Carolina at Chapel Hill, USA. Her current area of research focuses on anti-Markovnikov hydroamination of alkenes using photoredox catalysis.